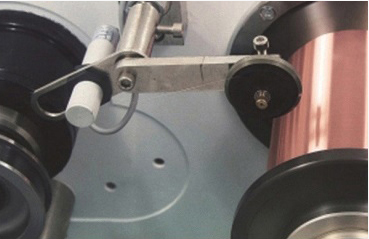

0.1mm x 250 strands Triple Insulated copper Litz wire

The triple insulation of TIW wire offers many advantages over traditional wire used in high voltage products.

Its sturdy construction ensures greater safety and reliability. Triple insulation provides an additional barrier against electrical breakdown, reducing the risk of insulation failure and potential accidents. This makes it an excellent choice for use in high-voltage environments such as power plants and substations.

The fluoropolymer insulation layer contributes to the excellent thermal stability of TIW wire. It can withstand high operating temperatures without compromising its electrical integrity, ensuring safe and efficient operation even under harsh conditions.

The unique combination of materials used in triple insulation provides excellent resistance to chemicals and solvents, making TIW wire suitable for use in harsh environments where exposure to such substances is common.

|

Item/No. |

Requirements |

Test Result |

Note |

|

Appearance |

Smooth surface, no black spots, no peeling, no copper exposure or cracking. |

OK |

|

|

Flexibility |

10 turns winding on rod, no crack, no wrinkles, no peeling |

OK |

|

|

Solderability |

420+/-5℃, 2-4s |

OK |

Can be peeled off, can be soldered |

|

Overall Diameter |

2.2+/-0.20mm |

2.187mm |

|

|

Conductor Diameter |

0.1+/-0.005mm |

0.105mm |

|

|

Resistance |

20℃, ≤9.81Ω/km |

5.43 |

|

|

Breakdown Voltage |

AC 6000V/60S, no breakdown of insulation |

OK |

|

|

Withstand Bending |

Withstand 3000V for 1min. |

OK |

|

|

Elongation |

≥15% |

18% |

|

|

Heat Shock |

≤150° 1hr 3d no crack |

OK |

|

|

Withstand friction |

Not less than 60 times |

OK |

|

|

Withstand temperature |

-80℃-220℃ high temperature test, no wrinkle on surface, no peeling, no crack |

OK |

The customizability of TIW wire further enhances its versatility and applicability across a variety of industries.

We can customize wire, including diameter, number of strands, and insulation, to meet your specific requirements.

This flexibility enables TIW wires to be used in a wide range of high-voltage applications such as power transformers, energy storage systems, electric vehicles and aerospace technology.

Customer Oriented,Innovation brings more Value

RUIYUAN is a solution provider, which requires us to be more professional on wires, insulation material and your applications.

Ruiyuan has a heritage of innovation, along with advancements in enameled copper wire, our company has grown through an unwavering commitment to integrity, service and responsiveness to our customers.

We look forward to continuing to grow on the basis of quality, innovation and service.

7-10 days Average delivery time.

90% European and North American customers. Such as PTR,ELSIT, STS etc.

95% Repurchase rate

99.3% Satisfaction rate. Class A supplier verified by German customer.