Self-soldering enameled copper wire

-

2UEW155 0.4mm Enameled Copper Winding Wire For Transformer/Motor

0.4mm enameled copper wire is a commonly used enameled wire and plays a vital role in the production of high-frequency transformers and motor windings. The product has a single wire diameter of 0.4mm and is widely praised for its excellent performance and versatility in a variety of electrical applications. The wire is coated with a solderable polyurethane enameled coating and is available in two different heat resistance ratings: 155°C and 180°C for different operating environments.

-

3UEW155 0.117mm Ultra-fine Enameled Copper Winding Wire For Electronic Devices

Enameled copper wire, also known as enameled wire, is a key component in the production of various electronic devices. This specialized wire offers superior conductivity and insulation properties and is designed to meet high industry standards.

-

2UEWF/H 0.04mm Green Color Super Thin Magnet Wire Enameled Copper Wire For Motor

The enameled copper wire produced by our company has many advantages in the field of information transmission, bringing excellent performance and reliability to the fields of electronic equipment manufacturing and communications.

Most of the enameled wires we produce are copper in color, but this specially customized green enameled copper wire is very popular. It uses polyurethane as the paint film component, has a temperature resistance level of 155 degrees, and is a high-quality ultra-fine wire. In addition to green, we can also customize enameled copper wires in other colors according to customer needs, such as blue, red, pink, etc.

-

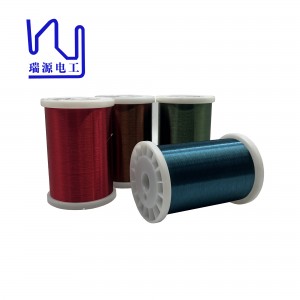

Blue / Green / Red /Brown Color Enameled Copper Wire For Winding Coils

Ruiyuan focuses on the production of enameled copper wire and is willing to customize it according to your special needs. Whether you need multiple colors including red, blue, green, brown, or yellow, we have you covered.

-

2UEW155 40 AWG 0.08mm Brown Color Motor Winding Insulated Copper Wire Solid

40 AWG 0.08mm brown and other custom color enameled wire for wide application in industrial fields.

Our 40 AWG 0.08mm enameled copper wire is a trustworthy choice because it is not only high quality, performs well, but is also available in a variety of custom colors.

-

44 AWG 0.05mm 2UEW/3UEW 155 Super Thin Red Color Magnet Wire Enameled Copper Winding Wire

The wire diameter of this wire is 0.05mm, polyurethane enamel layer, it’s solderable magnet wire and can be widely used in various industrial fields.

According to different application requirements, we provide enameled copper wire with temperature resistance levels of 155 degrees and 180 degrees. This means that the enameled copper wire can work in high temperature environments, has good heat resistance, and is not easy to deform or melt. Whether in the fields of automotive electronics, communication equipment or household appliances, this high-temperature enameled copper wire can play an outstanding role.

-

2UEWF/H 0.06mm Blue Color Polyurethane Enameled Copper Wire Magnet Wire

We provides high-quality enameled copper wire with excellent performance and wide range of applications.

The insulating layer of this film is usually made of polyurethane, which can effectively isolate conductive copper wires to prevent current leakage and short circuits.

-

2UEW 180 0.14mm Round Enameled Copper Winding Wire For Transformer

Enameled copper wire is a commonly used wire material. Its core is copper wire as a conductor, and polyurethane paint is used as a protective layer around it. Enameled wire has the properties of insulation and high temperature resistance, and is widely used in various fields.

-

Ultra Thin 0.025mm Class 180℃ SEIW Polyester-imide Solderable Insulated Round Enameled Copper Wire For Electric Motors

SEIW wire is an enameled copper wire with polyester-imide insulating layer. The temperature resistance grade is 180℃. Insulation of SEIW can be soldered directly without removing the insulating layer by manual or chemical methods, it make the soldering process simple, reduce the manufacturing cost and improves the efficiency. In addition,it has high temperature resistance, good adhesion of insulation layer and conductor, meet the requirements of winding that soldering and high heat resistance.

-

0.05mm Enameled Copper Wire for Ignition Coil

G2 H180

G3 P180

This product is UL certified, and the temperature rating is 180 degrees H180 P180 0UEW H180

G3 P180

Diameter range: 0.03mm—0.20mm

Applied standard: NEMA MW82-C, IEC 60317-2 -

SEIW 180 Polyester-imide Enameled copper wire

SEIW is composed of denatured polyesterimide as insulation which is solderable. In this case, SEIW can be resistant to high temperature as well as possesses property of soldering. It meets the needs of winding that requires soldering, high heat resistance and high impedance.

-

0.071mm Enameled Copper Wire for Electric Motor Winding

Enameled Copper Wire for Electric Motor produced by our company has good performance to resist high heat, abrasion, and corona.