Class 240 2.0mmx1.4mm Polyetheretherketone PEEK wire

PEEK wire, made from polyetheretherketone, is a high-performance material renowned for its exceptional properties, making it suitable for a wide range of demanding applications. This wire is particularly sought after in industries requiring high-temperature resistance, chemical stability, high strength, and superior electrical insulation.

Aerospace: PEEK wire is used in the aerospace field for its light weight, high temperature resistance, and ability to withstand extreme conditions. It is used to manufacture satellite cables and aircraft engine windings.

Automotive Industry: In automotive applications, PEEK wire is used for motor windings, particularly in high-voltage environments, where it helps reduce corona discharge and extend motor life. It is also used as cable ties for securing wiring and in the production of wear-resistant components.

Oil and Gas: The wire’s resistance to high and low temperatures, as well as chemical corrosion and radiation, makes it an ideal choice for motor windings in downhole equipment and submersible pumps.

Electronics and Semiconductors: In semiconductor manufacturing, PEEK wire is used to support and transport glass substrates, as well as in the production of electronic components and equipment.

Medical Industry: PEEK’s excellent biocompatibility and antimicrobial properties make it suitable for components of medical devices, including implants and surgical instruments.

Industrial Equipment: In the chemical industry, PEEK wire is used for fluid transportation and protective housings in harsh environments because it is resistant to acids and alkalis.

Renewable Energy: PEEK filament is also used in fuel cells and battery separators to improve performance and safety.

PEEK filament offers exceptional high-temperature resistance, maintaining mechanical integrity at temperatures up to 260°C. It exhibits strong chemical resistance to a wide range of acids and organic solvents, and is both strong and abrasion-resistant. Furthermore, its excellent electrical insulation properties over a wide temperature range, low outgassing, and robust radiation resistance make it suitable for environments exposed to radiation. Its biocompatibility further solidifies its position as the material of choice for medical implants.

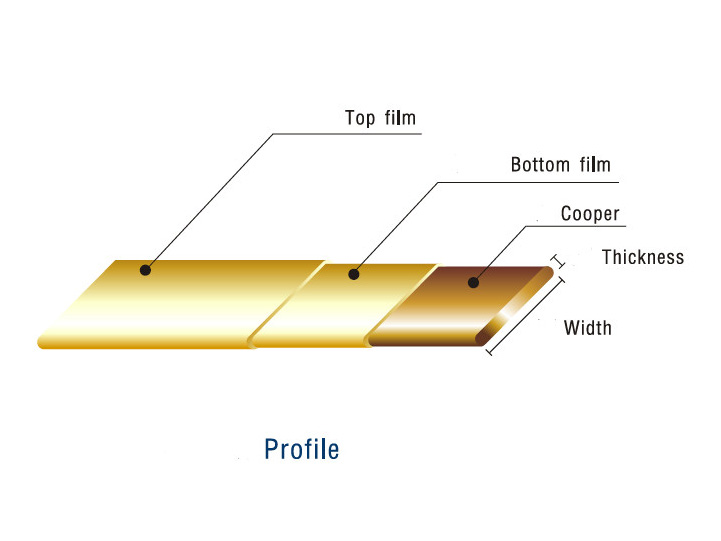

Technical Parameter Table Of PEEK WIRE 1.4mm*2.00mm rectangular enameled copper wire

| Ref.- | Item | Specification | Measurement data | |

| No. | W6070102A250904 | W6070102B250904 | ||

| 1 | Copper width | 1.980-2.020mm | 2.004 | 2.005 |

| 2 | Copper thickness | 1.380-1.420mm | 1.400 | 1.399 |

| 3 | Overall width | 2.300-2.360 mm | 2.324 | 2.321 |

| 4 | Overall thickness | 1.700-1.760 mm | 1.732 | 1.731 |

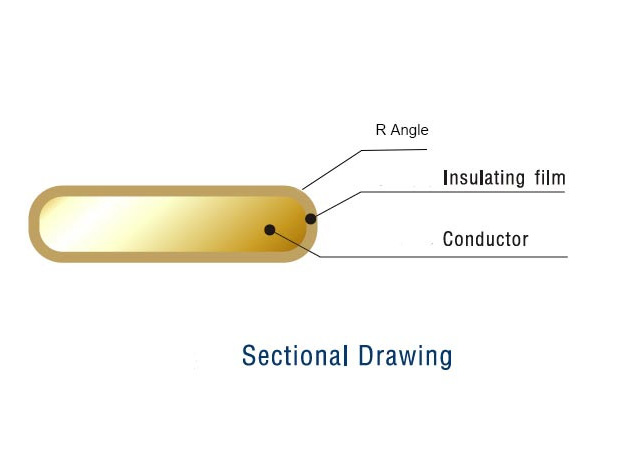

| 5 | Copper radius | 0.350-0.450mm | 0.375 | 0.408 |

| 6 | Copper radius | 0.385 | 0.412 | |

| 7 | Copper radius | 0.399 | 0.411 | |

| 8 | Copper radius | 0.404 | 0.407 | |

| 9 | Insulation layer thickness | 0.145-0.185mm | 0.170 | 0.159 |

| 10 | Insulation layer thickness | 0.162 | 0.155 | |

| 11 | Insulation layer thickness | 0.155 | 0.161 | |

| 12 | Insulation layer thickness | 0.167 | 0.165 | |

| 13 | Insulation layer thickness | 0.152 | 0.155 | |

| 14 | Insulation layer thickness | 0.161 | 0.159 | |

| 15 | Insulation layer thickness of radius | 0.145-0.185mm | 0.156 | 0.158 |

| 16 | Insulation layer thickness of radius | 0.159 | 0.155 | |

| 17 | Insulation layer thickness of radius | 0.154 | 0.159 | |

| 18 | Insulation layer thickness of radius | 0.160 | 0.165 | |

| 19 | Copper | T1 | OK | |

| 20 | Coating/Temperature grade | 240℃ | OK | |

| 21 | Elongation | ≥40% | 46 | 48 |

| 22 | Spring back angle | / | 5.186 | 5.098 |

| 23 | Flexibility | After winding wit

h Ø2.0mm and Ø3.0mmdiameter round rods, thereshould be no cracking in the insulation layer. |

OK | OK |

| 24 | Adhesion | ≤3.00mm | 0.394 | 0.671 |

| 25 | 20℃ Conductor resistance | ≤6.673 Ω/km | 6.350 | 6.360 |

| 26 | BDV | ≥12000 V | 22010 | 21170 |

5G Base Station Power Supply

Aerospace

Maglev Trains

Wind Turbines

New Energy Automobile

Electronics

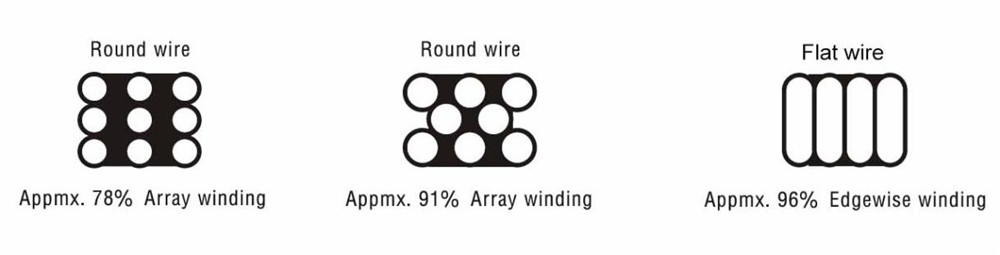

We produces costom rectangular enaemeled copper wire in temperature classes 155°C-240°C.

-Low MOQ

-Quick Delivery

-Top Quality

Ruiyuan attracts many outstanding technical and management talents, and our founders have built the best team in the industry with our long-term vision. We respects the values of each employee and provides them with a platform to make Ruiyuan a great place to grow a career.