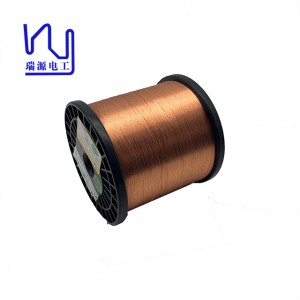

2UEWF 0.06mm*7 Stranded Copper Enameled Wire Litz Wire

This custom-made enameled stranded wire is made of 0.06mm direct-solder able polyurethane enameled round copper wire as a single wire, the number of twisted strands is 7, and the thermal class is 155 degrees. The customer uses this wire for high-frequency inductors to replace the previous enameled copper round wire. In order to reduce the high frequency current loss, reduce the impedance and increase the conductivity, we customized this stranded wire for the customer. To a large extent, the efficiency is improved and the heat generation is reduced.

This design balances the flux linkage and reactance of the individual strands so that the current is evenly distributed throughout the conductor. Then, the resistance ratios (AC vs. DC) tend toconverge. Custom stranded wire requires the engineer using the stranded wire knows the operating frequency and RMS current required for the application. Since the main benefit of Litz conductors is to reduce AC losses, the primary consideration for any Litz design is the operating frequency. Operating frequency not only affects the actual Litz structure, but is also used to determine individual wire gauges.

Our products have passed multiple certifications: ISO9001/ISO14001/IATF16949/UL/ROHS/REACH/VDE(F703)

|

single wire diameter (mm) |

0.06mm |

|

number of strands |

7 |

|

MaximumOutside Diameter(mm) |

0.25mm |

|

Insulation class |

class130/class155/class180 |

|

Film type |

Polyurethane/Polyurethane composite paint |

|

Film thickness |

0UEW/1UEW/2UEW/3UEW |

|

Twisted |

Single twist/multiple twist |

|

Pressure resistance |

>950V |

|

Stranding direction |

Forward/ Reverse |

|

lay length |

14±2 |

|

Color |

copper/red |

|

Reel Specifications |

PT-4/PT-10/PT-15 |

This customized product not only reduces the cost of customers, but also solves the problem of excessive current consumption of customers

5G base station power supply

EV Charging Stations

Industrial Motor

Maglev Trains

Medical Electronics

Wind Turbines

Founded in 2002, Ruiyuan has been in the manufacture of enamelled copper wire for 20 years.We combine the best manufacturing techniques and enamel materials to create a high-quality, best-in-class enameled wire. The enameled copper wire lies at the heart of technology we use every day – appliances, generators, transformers, turbines, coils and much more. Nowadays, Ruiyuan has the global footprint to support our partners in marketplace.

Our Team

Ruiyuan attracts many outstanding technical and management talents, and our founders have built the best team in the industry with our long-term vision. We respects the values of each employee and provides them with a platform to make Ruiyuan a great place to grow a career.