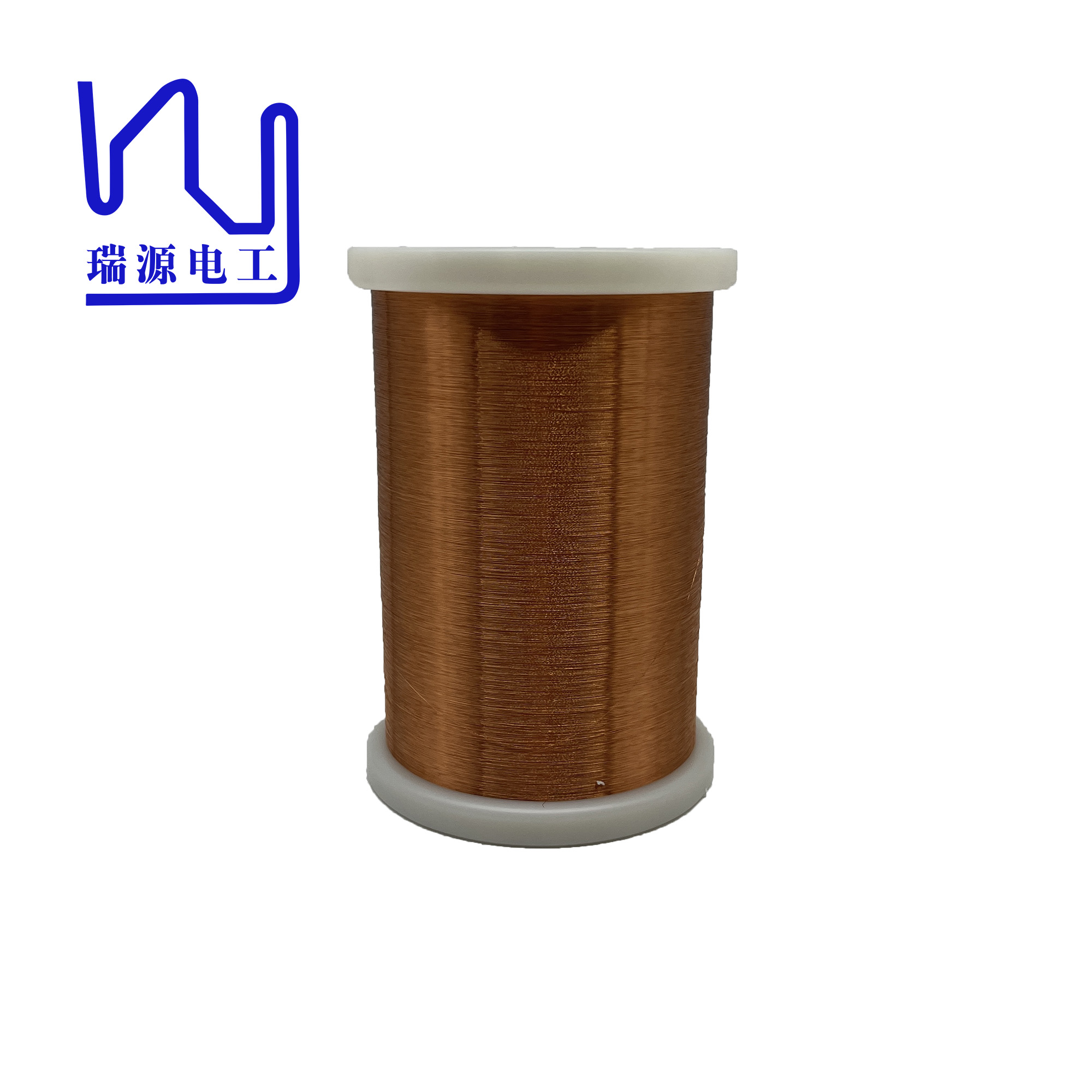

42.5 AWG 2UEW180 0.06mm polyurethane hot wind self adhesive enameled copper winding wire

Our ultra-fine self-adhesive enamelled copper wire is made of high-quality copper material, which has excellent electrical and thermal conductivity.

This ultra-fine self-adhesive enamelled copper wire stands out for its solderable design, excellent self-adhesive and excellent electrical conductivity. Its wide application in the field of audio coils has brought the performance of audio equipment to a whole new level.

·NEMA MW 132-C

·customized according to customer requirements.

1. The ultra-fine self-adhesive enameled copper wire can accommodate more wires in the same space, thus providing higher conductivity. This means that the audio signal can be transmitted more precisely, maintaining the purity and detail of the sound quality.

2.The wire has excellent self-adhesiveness, which makes the installation process more convenient. Thanks to the self-adhesive layer on the wire, our ultra-fine enamelled copper wire can be easily fixed at the target position without external auxiliary materials.

This not only saves you the trouble of finding suitable materials, but also saves construction time and improves production efficiency.

3.Our self-adhesive enamelled copper wire is made of high-quality copper material, which has excellent electrical and thermal conductivity.

Regardless of high-frequency or high-power environments, it can stably transmit audio signals and ensure the excellent performance of audio equipment.

In the field of audio coils, ultra-fine self-adhesive enamelled copper wires are widely used.

Audio coils are an important part of audio equipment, they are responsible for converting electrical signals into sound.

Ultra-fine self-adhesive enamelled copper wire makes the sound of audio equipment more clear and real by providing high conductivity and precise signal transmission. Whether it is speakers, headphones, recording equipment or audio amplifiers, you can enjoy the excellent performance brought by ultra-fine self-adhesive enameled copper wire.

| Test Item | Unit | Technical requests | Reality Value | ||

| Min. | Ave | Max | |||

| Conductor dimensions | mm | 0.060±0.002 | 0.060 | 0.060 | 0.060 |

| (Basecoat dimensions) Overall dimensions | mm | Max.0.077 | 0.0753 | 0.0753 | 0.0754 |

| Insulation Film Thickness | mm | Min. 0.003 | 0.004 | 0.004 | 0.004 |

| Bonding Film Thickness | mm | Min. 0.003 mm | 0.004 | 0.004 | 0.004 |

| Continuity of covering(50V/30m) | pcs | Max.60 | Max.0 | ||

| Adhesive | Coating layer is good | Good | |||

| Conductor Resistance(20℃) | Ω/km | 5.995-6.306 | 6. 16 | 6. 16 | 6. 17 |

| Elongation | % | Min. 17 | 24 | 25 | 25 |

| Breakdown Voltage | V | Min.700 | Min. 1526 | ||

| Bonding Strength | g | Min.8 | 15 | ||

| Resistance to Softening(Cut through) | ℃ | Continue 2 times pass | 200℃/Good | ||

| Solder test(390 ℃±5℃) | S | Max.2 | Max. 1.5 | ||

| Surface apperance | Smooth coloury | Good | |||

Automotive coil

sensor

special transformer

special micro motor

inductor

Relay

Customer Oriented,Innovation brings more Value

RUIYUAN is a solution provider, which requires us to be more professional on wires, insulation material and your applications.

Ruiyuan has a heritage of innovation, along with advancements in enameled copper wire, our company has grown through an unwavering commitment to integrity, service and responsiveness to our customers.

We look forward to continuing to grow on the basis of quality, innovation and service.

7-10 days Average delivery time.

90% European and North American customers. Such as PTR,ELSIT, STS etc.

95% Repurchase rate

99.3% Satisfaction rate. Class A supplier verified by German customer.