AIW220 1.0mm*0.3mm enameled flat copper wire For windings

This custom-made wire SFT-AIW 0.12mm*2.00mm is 220°C corona resistant Polyamideimide enameled flat wire. The customer uses this wire on the drive motor of the new energy vehicle. As the heart of new energy vehicles, there are many magnet wires in the drive motor. If the magnet wire and insulating material cannot withstand the high voltage, high temperature and high voltage change rate during the operation of the motor, they will be easily broken down and reduce the service life of the motor. At present, when most companies produce enameled wires for new energy vehicle drive motors, due to the simple process and single paint film, the products produced have poor corona resistance and poor thermal shock performance, thus affecting the service life of the drive motor. The birth of corona-resistant flat wire, a good solution to such problems! Better for customers to improve efficiency and reduce costs.

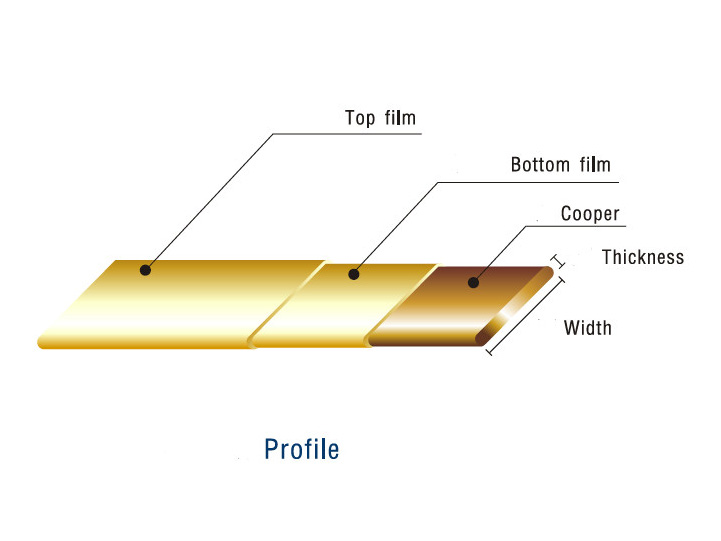

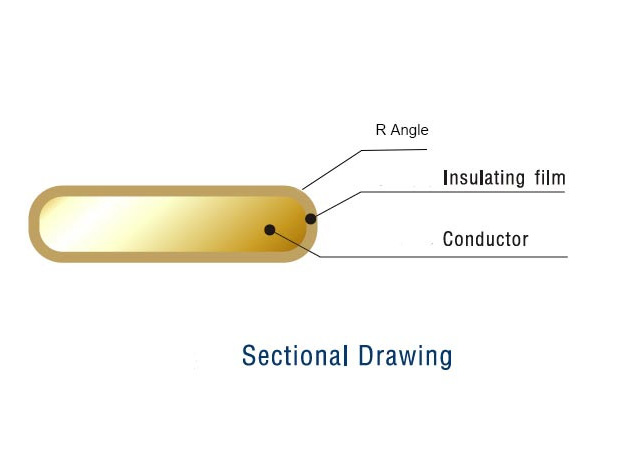

The 1mm*0.3mm enameled flat wire has a variety of remarkable properties and is very suitable for automotive industry applications. Its excellent 220-degree temperature resistance ensures that the flat wire can withstand the high operating temperatures commonly found in automotive systems. This makes it ideal for use in engines, exhaust systems and other high-temperature environments within vehicles. In addition, the polyamide-imide paint film has excellent electrical insulation properties, making the enameled flat wire suitable for electrical components and systems in automobiles.

In addition, the enameled copper flt wire has excellent resistance to chemicals and solvents, ensuring the durability and service life of enameled flat wires under the harsh conditions of automotive applications. This resistance to chemical degradation makes flat wire suitable for use in fuel delivery systems, oil circulation systems, and other components in contact with various automotive fluids. The excellent mechanical strength of the enamel coating further enhances the reliability of the enameled flat wire, allowing it to withstand vibration and mechanical stress in the automotive environment.

In the automotive industry, due to the advantages of this enameled flat wire has been widely used. It is commonly used to manufacture ignition systems, sensors, actuators and other electrical components within vehicles. Temperature resistance and excellent electrical insulation properties make it ideal for these critical automotive systems, ensuring reliable performance even under high temperature and high pressure conditions. In addition, enamelled rectangular wire can be used to produce coils, transformers and inductors for a variety of automotive applications, benefiting from the chemical resistance and mechanical strength provided by the enamel coating.

The 1mm*0.3mm enameled flat wire has a polyamide-imide paint film, which has excellent characteristics and advantages and is very suitable for use in the automotive industry. Its temperature resistance, electrical insulation, chemical resistance and mechanical strength make it ideal for a variety of automotive applications, helping to improve vehicle reliability and performance. As automotive technology continues to advance, the demand for high-quality enameled flat copper wires, such as the 1mm*0.3mm variant with polyamide-imide paint film, is expected to grow, further solidifying its importance in the automotive industry .

Technical Parameter Table Of SFT-AIW 0.3mm*1.00mm rectangular enameled copper wire

| Item | conductor

dimension |

Unilateral

insulationlayer thickness |

Overall

dimension |

breakdown

voltage |

Conductor resistance | ||||

| Unit | Thickness | Width | Thickness | Width | Thickness | Width | kv | Ω/km 20℃ | |

| mm | mm | mm | mm | mm | mm | ||||

| SPEC | Ave | 0.300 | 1.000 | 0.025 | 0.025 | ||||

| Max | 0.309 | 1.060 | 0.040 | 0.040 | 0.350 | 1.050 | 65.730 | ||

| Min | 0.291 | 0.940 | 0.010 | 0.010 | 0.340 | 1.030 | 0.700 | ||

| No. 1 | 0.298 | 0.984 | 0.022 | 0.029 | 0.342 | 1.042 | 1.520 | 62.240 | |

| No. 2 | 2.320 | ||||||||

| No. 3 | 1.320 | ||||||||

| No. 4 | 2.310 | ||||||||

| No. 5 | 1.185 | ||||||||

| Ave | 0.298 | 0.984 | 0.022 | 0.029 | 0.342 | 1.042 | 1.731 | ||

| NO.of reading | 1 | 1 | 1 | 1 | 1 | 1 | 5 | ||

| Min. reading | 0.298 | 0.984 | 0.022 | 0.029 | 0.342 | 1.042 | 1.185 | ||

| Max. reading | 0.298 | 0.984 | 0.022 | 0.029 | 0.342 | 1.042 | 2.320 | ||

| Range | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 1.135 | ||

| Result | OK | OK | OK | OK | OK | OK | OK | OK | |

5G Base Station Power Supply

Aerospace

Maglev Trains

Wind Turbines

New Energy Automobile

Electronics

We produces costom rectangular enaemeled copper wire in temperature classes 155°C-240°C.

-Low MOQ

-Quick Delivery

-Top Quality

Ruiyuan attracts many outstanding technical and management talents, and our founders have built the best team in the industry with our long-term vision. We respects the values of each employee and provides them with a platform to make Ruiyuan a great place to grow a career.