Best Price for 2UEW 155 Hot Wind Self Bonding Enameled Copper Wire - 0.011mm -0.025mm UEW Ultra-fine Enameled Copper Wire – Ruiyuan

Best Price for 2UEW 155 Hot Wind Self Bonding Enameled Copper Wire - 0.011mm -0.025mm UEW Ultra-fine Enameled Copper Wire – Ruiyuan Detail:

The selection of copper wire as raw materials and the process of drawing play a key role in fine wire drawing. With the 0.80mm copper wire drawn to 0.011mm, it has to go through several procedures such as middle draw and annealing, small draw and anealing, fine draw and micro drawing with annealing, In order to ensure the softness of wire, copper wire needs to be annealed every time when its cross section is compressed by 90%. Copper wire after drawing must keep bright, oxidation, discoloration and enamel stains must be avoided. Besides, the copper wire needs to be winded orderly and tightly on the take-up spool. We made a breakthrough in drawing 0.011mm fine enameled wire, and now we decidedly set our goal for 0.010mm.

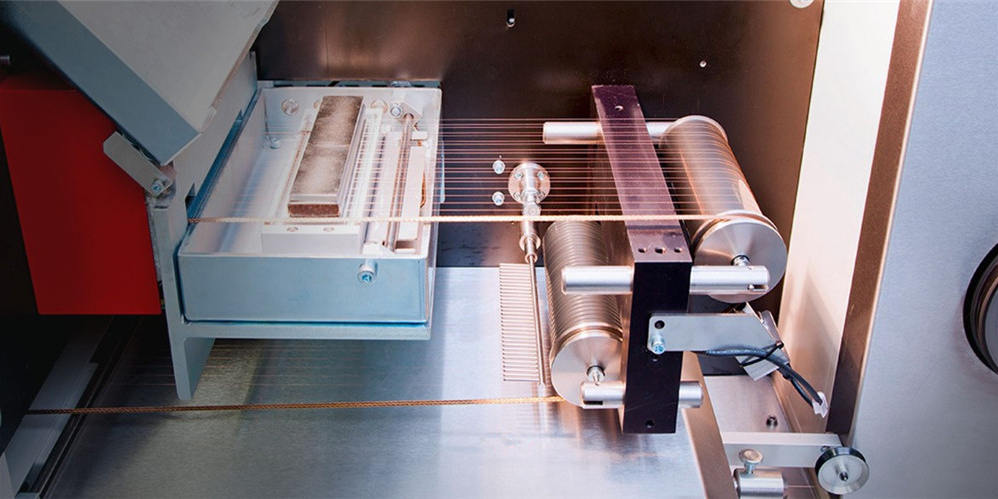

Regarding painting. First the drawn thin copper wire is cleaned of some impurities on the copper wire through felt to ensure quality of enameled wire during painting. Cleaned enameled wire is put into enamel tank. The wire passes through the paint rolling machine that keeps it fixed in the machine. As the rolling machine rotates with the enameled copper wire, the wire will not waggle up and down so that the paint is even and insufficient painting won’t happen. Hence good quality of painting is guaranteed.

-Solderable

-Soft raw materials for high-speed winding

-Good insulating property and consistent thickness of enamel

-Various colors to choose: natural color, red, pink, green, blue, black, etc.

| NominalDiameter |

Enameled Copper Wire (overall diameter) |

Resistance at 20 °C

|

||||||

|

Grade 1 |

Grade 2 |

Grade 3 |

||||||

| [mm] |

min [mm] |

max [mm] |

min [mm] |

max [mm] |

min [mm] |

max [mm] |

min [Ohm/m] |

max [Ohm/m] |

| 0.010 |

0.012 |

0.013 |

0.014 |

0.016 |

0.017 |

0.019 |

195.88 |

239.41 |

| 0.012 |

0.014 |

0.016 |

0.017 |

0.018 |

0.019 |

0.021 |

136.03 |

166.26 |

| 0.014 |

0.016 |

0.018 |

0.019 |

0.020 |

0.021 |

0.023 |

99.94 |

122.15 |

| 0.016 |

0.018 |

0.020 |

0.021 |

0.022 |

0.023 |

0.025 |

76.52 |

93.52 |

| 0.018 |

0.020 |

0.022 |

0.023 |

0.024 |

0.025 |

0.026 |

60.46 |

73.89 |

| 0.019 |

0.021 |

0.023 |

0.024 |

0.026 |

0.027 |

0.028 |

54.26 |

66.32 |

| 0.020 |

0.022 |

0.024 |

0.025 |

0.027 |

0.028 |

0.030 |

48.97 |

59.85 |

| 0.021 |

0.023 |

0.026 |

0.027 |

0.028 |

0.029 |

0.031 |

44.42 |

54.29 |

| 0.022 |

0.024 |

0.027 |

0.028 |

0.030 |

0.031 |

0.033 |

40.47 |

49.47 |

| 0.023 |

0.025 |

0.028 |

0.029 |

0.031 |

0.032 |

0.034 |

37.03 |

45.26 |

| 0.024 |

0.026 |

0.029 |

0.030 |

0.032 |

0.033 |

0.035 |

34.01 |

45.56 |

| 0.025 |

0.028 |

0.031 |

0.032 |

0.034 |

0.035 |

0.037 |

31.34 |

38.31 |

| NominalDiameter

|

Elongation acc to IEC |

Breakdown Voltage acc to IEC |

Winding Tension |

||

|

Grade 1 |

Grade 2 |

Grade 3 |

|||

|

min [%] |

max [cN] |

||||

|

0.010 |

3 |

70 |

125 |

170 |

1.4 |

|

0.012 |

3 |

80 |

150 |

190 |

2.0 |

|

0.014 |

4 |

90 |

175 |

230 |

2.5 |

|

0.016 |

5 |

100 |

200 |

290 |

3.2 |

|

0.018 |

5 |

110 |

225 |

350 |

3.9 |

|

0.019 |

6 |

115 |

240 |

380 |

4.3 |

|

0.020 |

6 |

120 |

250 |

410 |

4.4 |

|

0.021 |

6 |

125 |

265 |

440 |

5.1 |

|

0.022 |

6 |

130 |

275 |

470 |

5.5 |

|

0.023 |

7 |

145 |

290 |

470 |

6.0 |

|

0.024 |

7 |

145 |

290 |

470 |

6.5 |

|

0.025 |

7 |

150 |

300 |

470 |

7.0 |

Transformer

Motor

Ignition coil

Voice Coil

Electrics

Relay

Drawing

Paint

Annealing

Baking

Cooling

Customer Oriented,Innovation brings more Value

RUIYUAN is a solution provider, which requires us to be more professional on wires, insulation material and your applications.

Ruiyuan has a heritage of innovation, along with advancements in enameled copper wire, our company has grown through an unwavering commitment to integrity, service and responsiveness to our customers.

We look forward to continuing to grow on the basis of quality, innovation and service.

7-10 days Average delivery time.

90% European and North American customers. Such as PTR,ELSIT, STS etc.

95% Repurchase rate

99.3% Satisfaction rate. Class A supplier verified by German customer.

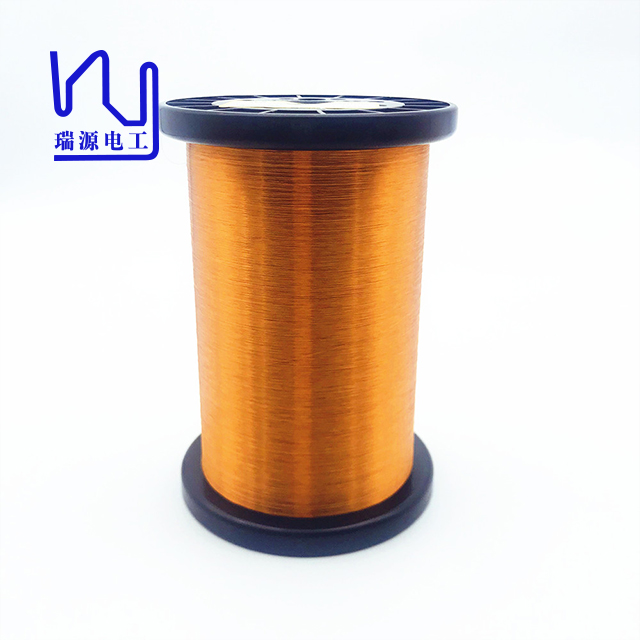

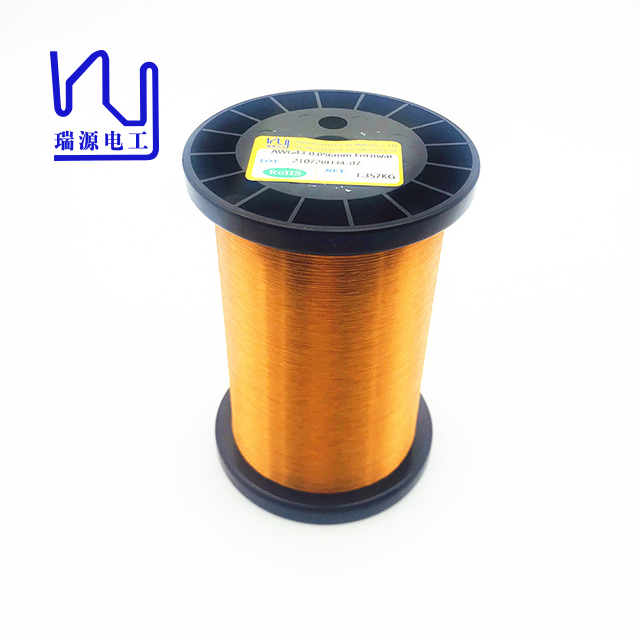

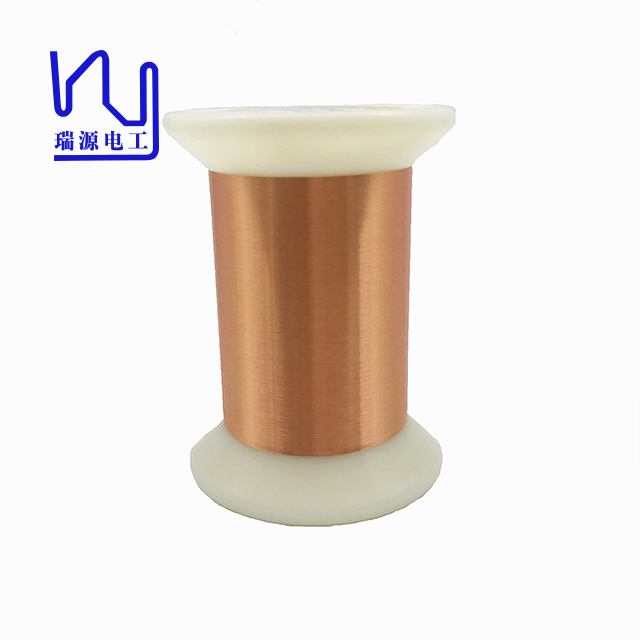

Product detail pictures:

Related Product Guide:

To meet the customers' over-expected gratification , we have our robust crew to offer our best over-all support which includes marketing, income, coming up with, production, excellent managing, packing, warehousing and logistics for Best Price for 2UEW 155 Hot Wind Self Bonding Enameled Copper Wire - 0.011mm -0.025mm UEW Ultra-fine Enameled Copper Wire – Ruiyuan , The product will supply to all over the world, such as: Albania, Peru, Israel, We have sufficient experience in producing products according to samples or drawings. We warmly welcome customers from home and abroad to visit our company, and to cooperate with us for a splendid future together.

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.