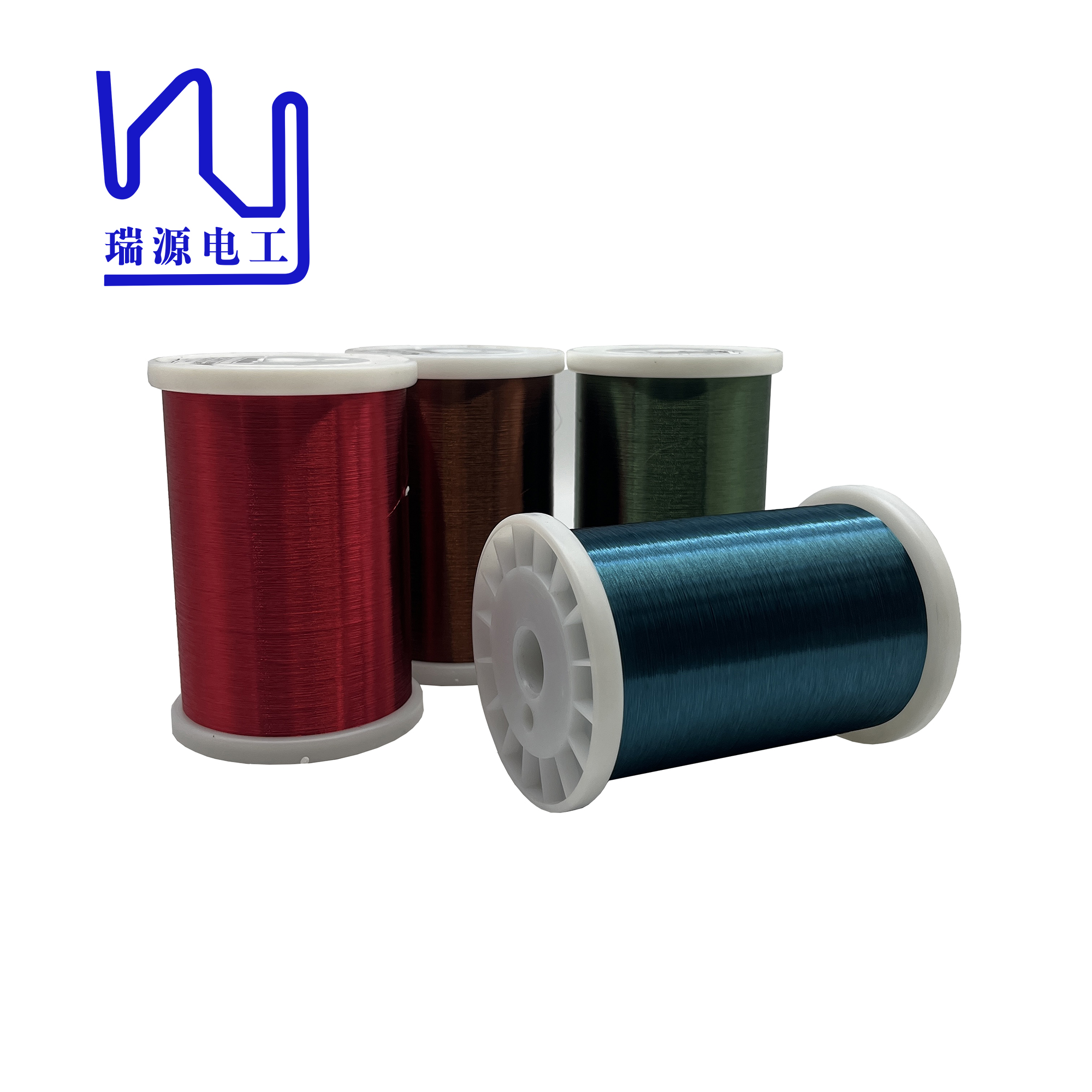

Blue / Green / Red /Brown Color Enameled Copper Wire For Winding Coils

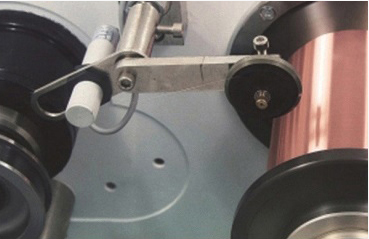

The production process of enameled copper wire is a complex and precise process that requires multiple links to ensure quality and performance.

First of all, we choose high-purity copper as raw material to ensure the conductivity and reliability of the product.

Then, by introducing advanced enameling technology, we evenly coat the insulating material on the copper wires to form a protective layer to prevent current leakage and short circuits.

Finally, a strict quality inspection process is carried out to ensure that each colored enameled copper wire meets industry standards and customer requirements.

·IEC 60317-23

·NEMA MW 77-C

·customized according to customer requirements.

The production process of enameled copper wire is a complex and precise process that requires multiple links to ensure quality and performance.

First of all, we choose high-purity copper as raw material to ensure the conductivity and reliability of the product.

Then, by introducing advanced enameling technology, we evenly coat the insulating material on the copper wires to form a protective layer to prevent current leakage and short circuits.

Finally, a strict quality inspection process is carried out to ensure that each colored enameled copper wire meets industry standards and customer requirements.

|

Test Items |

Requirements |

Test Data |

|||

|

|

|

1st Sample |

2nd Sample |

3rd Sample |

|

| Appearance |

Smooth & Clean |

OK |

OK |

OK |

|

| Conductor Diameter |

0.060mm ± |

0.002mm |

0.0600 |

0.0600 |

0.0600 |

| Thickness of Insulation |

≥ 0.008mm |

0.0120 |

0.0120 |

0.0110 |

|

| Overall Diameter |

≤ 0.074mm |

0.0720 |

0.0720 |

0.0710 |

|

| DC Resistance |

≤6.415 Ω/m |

6.123 |

6.116 |

6.108 |

|

| Elongation |

≥ 14% |

21.7 |

20.3 |

22.6 |

|

| Breakdown Voltage |

≥500V |

1725 |

1636 |

1863 |

|

| Pin Hole |

≤ 5 faults/5m |

0 |

0 |

0 |

|

| Adherence |

No cracks visible |

OK |

OK |

OK |

|

| Cut-through |

200℃ 2min No breakdown |

OK |

OK |

OK |

|

| Heat Shock |

175±5℃/30min No cracks |

OK |

OK |

OK |

|

| Solderability |

390± 5℃ 2 Sec No slags |

OK |

OK |

OK |

|

| Insulation Continuity |

≤ 60(faults)/30m |

0 |

0 |

0 |

|

The quality of our enameled copper wire is reliable and can provide stable electrical performance to ensure the safe operation of equipment and systems.

We are willing to provide customized services according to your special needs and ensure product quality and performance.

Please contact us and we will be happy to provide you with a satisfactory solution.

Automotive coil

sensor

special transformer

special micro motor

inductor

Relay

Customer Oriented,Innovation brings more Value

RUIYUAN is a solution provider, which requires us to be more professional on wires, insulation material and your applications.

Ruiyuan has a heritage of innovation, along with advancements in enameled copper wire, our company has grown through an unwavering commitment to integrity, service and responsiveness to our customers.

We look forward to continuing to grow on the basis of quality, innovation and service.

7-10 days Average delivery time.

90% European and North American customers. Such as PTR,ELSIT, STS etc.

95% Repurchase rate

99.3% Satisfaction rate. Class A supplier verified by German customer.