Chinese Professional Electric Motor Winding Wire - 0.05mm Enameled Copper Wire for Ignition Coil – Ruiyuan

Chinese Professional Electric Motor Winding Wire - 0.05mm Enameled Copper Wire for Ignition Coil – Ruiyuan Detail:

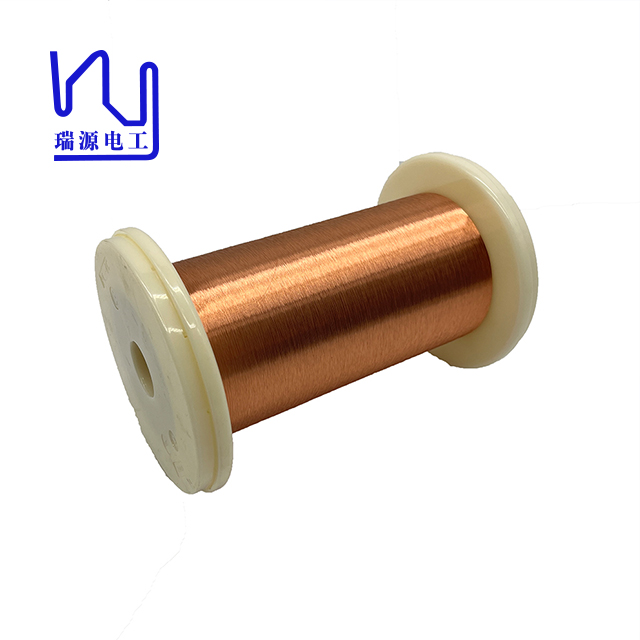

The working principle of automobile ignition coil is to convert low voltage of DC power to high voltage of DC by inversion and dual voltage rectification which passes through the primary of the ignition coil intermittently. A high voltage is induced in the secondary of the ignition coil ( Generally around 20KV) and then it drives the spark plug of ignition coil to discharge for ignition. It’s difficult to control some properties of conventional enameled wire for automotive ignition coils as broken wire often occurs during process. Considering special requirements of ignition coils, our company designs a unique enameled wire for automotive ignition coils with excellent appearance, good solderability, high softening resistance and stability during manufacturing. We use drawn copper wire that is initially covered with base coat soldering at low temperature. Then the wire is additionally coated with softening-resistant enamel. Components of this wire is polyurethane with high temperature resistance.

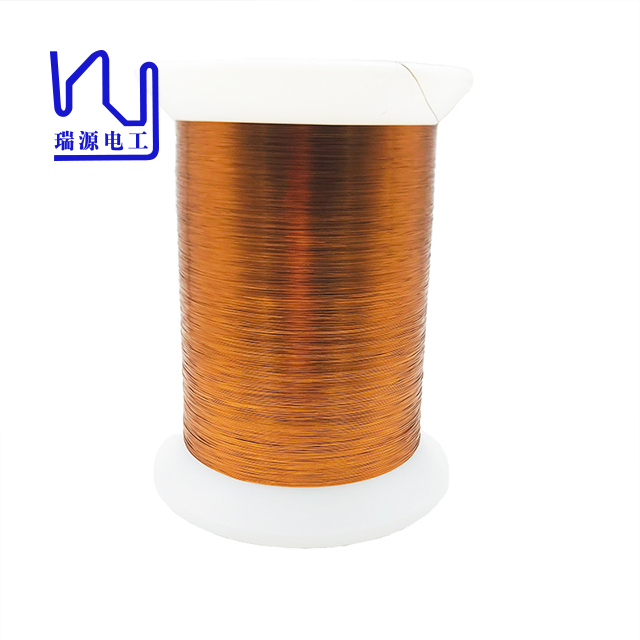

One of the characteristics of enameled wire (G2 H0.03-0.10) for the secondary of automobile ignition coil is that its diameter is extremely thin. The thinnest is only about one-third of human hair. Moreover, as it is a wire with thick polyurethane enamel of thermal class 180C, it has rather high demands on the manufacturing process. Our company has abundant experience and mature and advanced technology in enameled wire design for automotive ignition coil. The production process is stable.

1. Improvement of the softening resistance so at not to break during softening breakdown under the condition of 260℃*2min.

2. better soldering performance, the soldering surface is smooth and clean without solder slag under the condition of 390℃*2S.

The rate for wire breakage in the production process is reduced from more than 20% to less than 1%, so that the surface is smoother and the conductivity is stable.

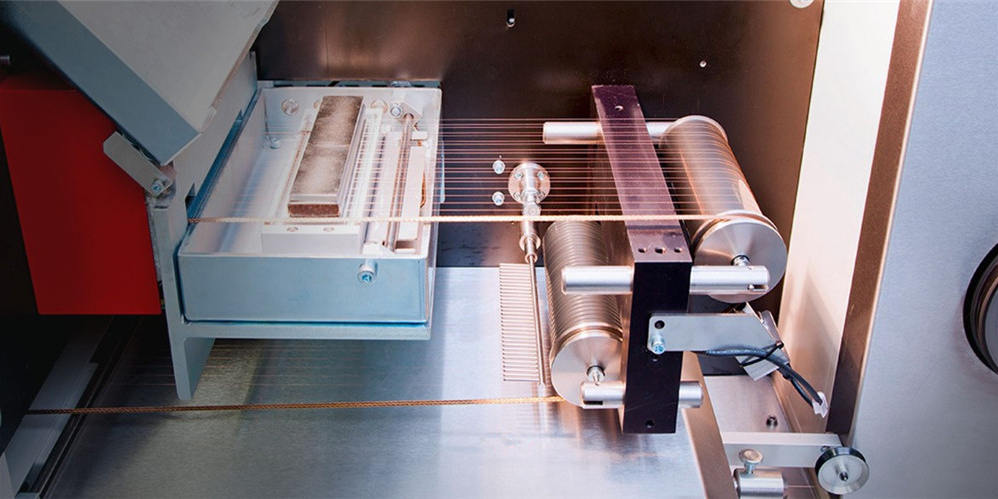

1. We adopts a composite insulation: enamel with low temperature soldering property is used as base coat, and enamel with high softening resistance as topcoat to produce composite enameled wire with good solderability and high softening resistance.

2. Improvement the production technology of enameled wire: change of concentration of drawing oil during drawing. Mould set for manufacture management is conducive to smooth surface of copper wire. Installation of automatic viscosity adjustment device and automatic tension control device in the enamelling process reduces the rate for wire breakage.

| Diameter | Tolrance |

Enameled copper wire(overall diameter) |

|||||

| (mm) | (mm) | Grade 1 | Grade 2 | Grade 3 | |||

|

Min.(mm) |

Max.(mm) |

Min.(mm) |

Max.(mm) |

Min.(mm) |

Max.(mm) |

||

|

0.030 |

* |

0.033 |

0.037 |

0.038 |

0.041 |

0.042 |

0.044 |

|

0.032 |

* |

0.035 |

0.039 |

0.04 |

0.043 |

0.044 |

0.047 |

|

0.034 |

* |

0.037 |

0.041 |

0.042 |

0.046 |

0.047 |

0.05 |

|

0.036 |

* |

0.04 |

0.044 |

0.045 |

0.049 |

0.05 |

0.053 |

|

0.038 |

* |

0.042 |

0.046 |

0.047 |

0.051 |

0.052 |

0.055 |

|

0.040 |

* |

0.044 |

0.049 |

0.05 |

0.054 |

0.055 |

0.058 |

|

0.043 |

* |

0.047 |

0.052 |

0.053 |

0.058 |

0.059 |

0.063 |

|

0.045 |

* |

0.05 |

0.055 |

0.056 |

0.061 |

0.062 |

0.066 |

|

0.048 |

* |

0.053 |

0.059 |

0.06 |

0.064 |

0.065 |

0.069 |

|

0.050 |

* |

0.055 |

0.06 |

0.061 |

0.066 |

0.067 |

0.072 |

|

0.053 |

* |

0.058 |

0.064 |

0.065 |

0.07 |

0.071 |

0.076 |

|

0.056 |

* |

0.062 |

0.067 |

0.068 |

0.074 |

0.075 |

0.079 |

|

0.060 |

* |

0.066 |

0.072 |

0.073 |

0.079 |

0.08 |

0.085 |

|

0.063 |

* |

0.069 |

0.076 |

0.077 |

0.083 |

0.084 |

0.088 |

|

0.067 |

* |

0.074 |

0.08 |

0.081 |

0.088 |

0.089 |

0.091 |

|

0.070 |

* |

0.077 |

0.083 |

0.084 |

0.09 |

0.091 |

0.096 |

|

0.071 |

±0.003 |

0.078 |

0.084 |

0.085 |

0.091 |

0.092 |

0.096 |

|

0.075 |

±0.003 |

0.082 |

0.089 |

0.09 |

0.095 |

0.096 |

0.102 |

|

0.080 |

±0.003 |

0.087 |

0.094 |

0.095 |

0.101 |

0.102 |

0.108 |

|

0.085 |

±0.003 |

0.093 |

0.1 |

0.101 |

0.107 |

0.108 |

0.114 |

|

0.090 |

±0.003 |

0.098 |

0.105 |

0.106 |

0.113 |

0.114 |

0.12 |

|

0.095 |

±0.003 |

0.103 |

0.111 |

0.112 |

0.119 |

0.12 |

0.126 |

|

0.100 |

±0.003 |

0.108 |

0.117 |

0.118 |

0.125 |

0.126 |

0.132 |

|

0.106 |

±0.003 |

0.115 |

0.123 |

0.124 |

0.132 |

0.133 |

0.14 |

|

0.110 |

±0.003 |

0.119 |

0.128 |

0.129 |

0.137 |

0.138 |

0.145 |

|

0.112 |

±0.003 |

0.121 |

0.13 |

0.131 |

0.139 |

0.14 |

0.147 |

|

0.118 |

±0.003 |

0.128 |

0.136 |

0.137 |

0.145 |

0.146 |

0.154 |

|

0.120 |

±0.003 |

0.13 |

0.138 |

0.139 |

0.148 |

0.149 |

0.157 |

|

0.125 |

±0.003 |

0.135 |

0.144 |

0.145 |

0.154 |

0.155 |

0.163 |

|

0.130 |

±0.003 |

0.141 |

0.15 |

0.151 |

0.16 |

0.161 |

0.169 |

|

0.132 |

±0.003 |

0.143 |

0.152 |

0.153 |

0.162 |

0.163 |

0.171 |

|

0.140 |

±0.003 |

0.151 |

0.16 |

0.161 |

0.171 |

0.172 |

0.181 |

|

0.150 |

±0.003 |

0.162 |

0.171 |

0.172 |

0.182 |

0.183 |

0.193 |

|

0.160 |

±0.003 |

0.172 |

0.182 |

0.183 |

0.194 |

0.195 |

0.205 |

|

0.170 |

±0.003 |

0.183 |

0.194 |

0.195 |

0.205 |

0.206 |

0.217 |

|

0.180 |

±0.003 |

0.193 |

0.204 |

0.205 |

0.217 |

0.218 |

0.229 |

|

0.190 |

±0.003 |

0.204 |

0.216 |

0.217 |

0.228 |

0.229 |

0.24 |

|

0.200 |

±0.003 |

0.214 |

0.226 |

0.227 |

0.239 |

0.24 |

0.252 |

|

Diameter |

Tolrance |

Resistance at 20 °C |

||

|

mm |

mm |

Nom(ohm/m) |

Min(ohm/m) |

Max(ohm/m) |

|

0.030 |

* |

24.18 |

21.76 |

26.6 |

|

0.032 |

* |

21.25 |

19.13 |

23.38 |

|

0.034 |

* |

18.83 |

17.13 |

20.52 |

|

0.036 |

* |

16.79 |

15.28 |

18.31 |

|

0.038 |

* |

15.07 |

13.72 |

16.43 |

|

0.040 |

* |

13.6 |

12.38 |

14.83 |

|

0.043 |

* |

11.77 |

10.71 |

12.83 |

|

0.045 |

* |

10.75 |

9.781 |

11.72 |

|

0.048 |

* |

9.447 |

8.596 |

10.3 |

|

0.050 |

* |

8.706 |

7.922 |

9.489 |

|

0.053 |

* |

7.748 |

7.051 |

8.446 |

|

0.056 |

* |

6.94 |

6.316 |

7.565 |

|

0.060 |

* |

6.046 |

5.502 |

6.59 |

|

0.063 |

* |

5.484 |

4.99 |

5.977 |

|

0.067 |

* |

4.848 |

4.412 |

5.285 |

|

0.070 |

* |

4.442 |

4.042 |

4.842 |

|

0.071 |

±0.003 |

4.318 |

3.929 |

4.706 |

|

0.075 |

±0.003 |

3.869 |

3.547 |

4.235 |

|

0.080 |

±0.003 |

3.401 |

3.133 |

3.703 |

|

0.085 |

±0.003 |

3.012 |

2.787 |

3.265 |

|

0.090 |

±0.003 |

2.687 |

2.495 |

2.9 |

|

0.095 |

±0.003 |

2.412 |

2.247 |

2.594 |

|

0.100 |

±0.003 |

2.176 |

2.034 |

2.333 |

|

0.106 |

±0.003 |

1.937 |

1.816 |

2.069 |

|

0.110 |

±0.003 |

1.799 |

1.69 |

1.917 |

|

0.112 |

±0.003 |

1.735 |

1.632 |

1.848 |

|

0.118 |

±0.003 |

1.563 |

1.474 |

1.66 |

|

0.120 |

±0.003 |

1.511 |

1.426 |

1.604 |

|

0.125 |

±0.003 |

1.393 |

1.317 |

1.475 |

|

0.130 |

±0.003 |

1.288 |

1.22 |

1.361 |

|

0.132 |

±0.003 |

1.249 |

1.184 |

1.319 |

|

0.140 |

±0.003 |

1.11 |

1.055 |

1.17 |

|

0.150 |

±0.003 |

0.9673 |

0.9219 |

1.0159 |

|

0.160 |

±0.003 |

0.8502 |

0.8122 |

0.8906 |

|

0.170 |

±0.003 |

0.7531 |

0.7211 |

0.7871 |

|

0.180 |

±0.003 |

0.6718 |

0.6444 |

0.7007 |

|

0.190 |

±0.003 |

0.6029 |

0.5794 |

0.6278 |

|

0.200 |

±0.003 |

0.5441 |

0.5237 |

0.5657 |

Transformer

Motor

Ignition coil

Voice Coil

Electrics

Relay

Drawing

Paint

Annealing

Baking

Cooling

Customer Oriented,Innovation brings more Value

RUIYUAN is a solution provider, which requires us to be more professional on wires, insulation material and your applications.

Ruiyuan has a heritage of innovation, along with advancements in enameled copper wire, our company has grown through an unwavering commitment to integrity, service and responsiveness to our customers.

We look forward to continuing to grow on the basis of quality, innovation and service.

7-10 days Average delivery time.

90% European and North American customers. Such as PTR,ELSIT, STS etc.

95% Repurchase rate

99.3% Satisfaction rate. Class A supplier verified by German customer.

Product detail pictures:

Related Product Guide:

Innovation, good quality and reliability are the core values of our enterprise. These principles today extra than ever form the basis of our success as an internationally active mid-size organization for Chinese Professional Electric Motor Winding Wire - 0.05mm Enameled Copper Wire for Ignition Coil – Ruiyuan , The product will supply to all over the world, such as: Iraq, Cairo, South Africa, We are fully aware of our customer's needs. We provide high quality products, competitive prices and the first class service. We would like to establish good business relationships as well as friendship with you in the near future.

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!