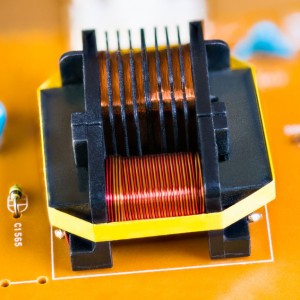

Custom 2UDTC-F 0.1mmx300 High Frequency Silk Covered Litz Wire For Transformer Winding

This silk covered litz wire is made from 0.1mm enameled wire, it has a heat resistance rating of 155 degrees Celsius, for those customers who require higher temperature resistance, we offer custom options that increase heat resistance to 180 degrees Celsius. This adaptability makes our wire-covered litz wire suitable for a wide range of applications, from high-performance transformers to automotive wiring systems, where reliability and safety are critical.

The construction of our Litz wire is a testament to our commitment to quality. This litz wire consists of 300 strands, and it's covered with durable nylon yarn with a double wrapping to enhance its structural integrity. Stranded wire minimizes skin and proximity effects, allowing for better current distribution and reduced energy loss, which is critical in high-frequency applications.

We understand that every project has unique requirements, which is why we support small batch customization with a minimum order quantity of only 10 kg. Whether you require a specific single wire diameter (from a minimum of 0.03 mm to a maximum of 10,000 strands), or a different covering material (such as polyester yarn or silk), we can produce the wire to your design specifications.

The applications for silk covered litz wire are wide and varied. In transformer windings, the wire's excellent electrical conductivity and heat resistance ensure efficient energy transfer and minimal losses, thereby helping to improve the overall performance of the transformer.

In the automotive industry, where reliability and safety are paramount, our wire-covered litz wire is used in a variety of electrical systems, from ignition coils to battery connections. By choosing our custom silk covered litz wire, you are investing in a product that not only meets but exceeds industry standards, ensuring your project is built on quality and reliability.

| Characteristics | Technical requests | Test Results |

| Conductor diameter(mm) | 0.10±0.003 | 0.098-0.10 |

| Overall diameter(mm) | Max.2.99 | 2.28-2.40 |

| No. Of strands | 300 | √ |

| Pitch(mm) | 47±3 | √ |

| Maximum Resistance(Ω/m 20℃) | 0.007937 | 0.00719 |

| Minimum Breakdown Voltage(V) | 1100 | 3100 |

| Solderability | 390±5℃, 9s | √ |

| Pinhole(faults/6m) | Max. 66 | 33 |

Founded in 2002, Ruiyuan has been in the manufacture of enamelled copper wire for 20 years.We combine the best manufacturing techniques and enamel materials to create a high-quality, best-in-class enameled wire. The enameled copper wire lies at the heart of technology we use every day – appliances, generators, transformers, turbines, coils and much more. Nowadays, Ruiyuan has the global footprint to support our partners in marketplace.

Our Team

Ruiyuan attracts many outstanding technical and management talents, and our founders have built the best team in the industry with our long-term vision. We respects the values of each employee and provides them with a platform to make Ruiyuan a great place to grow a career.