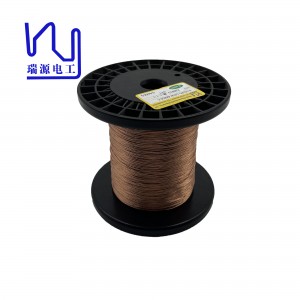

Custom Made Taped Litz Wire 120/0.4mm Polyesterimide High Frequency Copper Wire

Taped Litz wire is a high-frequency copper Litz wire, which is twisted by multiple enameled wires. During the production process of the coated Litz wire, polyesterimide film (PI fim) is wrapped on the outside of the wires to improve their insulation performance and temperature resistance, and to protect the internal enameled wires from the external environment.

|

Test report for litz wire served with tape Spec: 2UEW-F-PI 0.4mm*120 |

||

|

Characteristics |

Technical requests |

Test Results |

|

Outer diameter of single wire(mm) |

0.422-0.439 |

0.428-0.433 |

|

Conductor diameter(mm) |

0.40±0.005 |

0.397-0.400 |

|

Overall dimension(mm) |

Max. 6.45 |

5.56-6.17 |

|

No. Of strands |

120 |

120 |

|

Pitch(mm) |

130±20 |

130 |

|

Maximum Resistance(Ω/m 20℃) |

0.001181 |

0.001110 |

|

Dielectric strength(V) |

Min.6000 |

12000 |

|

Tape(overlap %) |

Min.50 |

54 |

Taped Litz wire has the advantages of electromagnetic shielding and anti-interference, which is very useful in high-frequency and miniaturized transmission, and is widely used in electronic equipment, communication and other fields

With these characteristics, taped Litz wire has been widely used in various industrial fields such as power capacitors, transformers, motors, automobiles, and aerospace. Electrical insulation performance, very suitable for high temperature, high pressure, high frequency environment.

We accept small batch customization, the minimum order quantity is 10kg.

Applying the Taped Litz wire to the manufacture of transformers can significantly improve the energy efficiency of the transformer, reduce power loss and prolong the service life of the equipment.

Taped Litz wire is used as the insulation material of motors and motors, which can improve the output power and efficiency of the system, help electrical equipment avoid losses caused by problems such as arcing, and ensure safe and efficient operation of equipment.

Taped Litz wire is also useful in the automotive field and is an important part of automotive electronic systems. The temperature resistance and electrical insulation properties of taped Litz wire make it ideal for automotive electrical safety and performance stability.

With the continuous development of automotive electronic systems, the requirements for electrical insulating materials will become higher and higher, and the taped Litz wire will also have a bright future. In the aerospace field, polyester imide film (PI fim) is also a very important material.

High-performance polyester-imide film (PI fim) is the most suitable material for manufacturing high-temperature sensors and spacecraft, providing excellent electrical insulation and durability even in high-temperature environments. Therefore,taped Litz wire is also one of the important materials for manufacturing high-performance aerospace electrical equipment.

5G base station power supply

EV Charging Stations

Industrial Motor

Maglev Trains

Medical Electronics

Wind Turbines

Founded in 2002, Ruiyuan has been in the manufacture of enamelled copper wire for 20 years.We combine the best manufacturing techniques and enamel materials to create a high-quality, best-in-class enameled wire. The enameled copper wire lies at the heart of technology we use every day – appliances, generators, transformers, turbines, coils and much more. Nowadays, Ruiyuan has the global footprint to support our partners in marketplace.

Our Team

Ruiyuan attracts many outstanding technical and management talents, and our founders have built the best team in the industry with our long-term vision. We respects the values of each employee and provides them with a platform to make Ruiyuan a great place to grow a career.