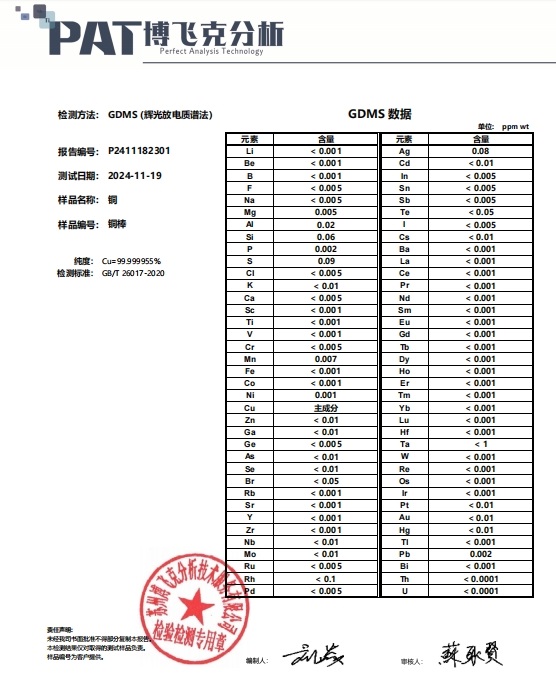

High Purity 99.9999% 6N Copper Pellets For Evaporation

High purity copper pellets, such as those with a purity of 99.9999% (often referred to as “six nines” copper), offer several advantages, particularly in specialized applications. Here are some key benefits:

Electrical Conductivity: High purity copper has superior electrical conductivity compared to lower purity grades. This makes it ideal for applications in electrical wiring, connectors, and components where efficient current flow is critical.

Thermal Conductivity: Similar to its electrical properties, high purity copper also exhibits excellent thermal conductivity, making it suitable for heat exchangers, cooling systems, and other applications where heat transfer is important.

Corrosion Resistance: Higher purity levels can enhance the corrosion resistance of copper, making it more durable in harsh environments. This is particularly beneficial in applications exposed to moisture or corrosive substances

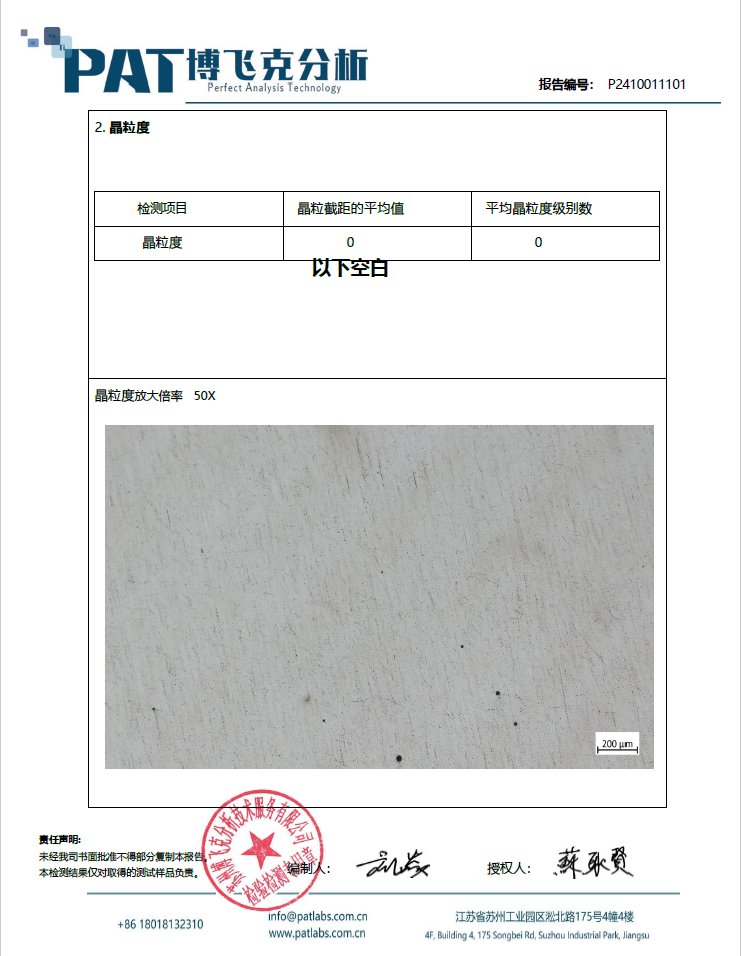

Reduced Impurities: The absence of impurities minimizes the risk of defects in the material, leading to improved mechanical properties and performance. This is crucial in high-stakes applications such as aerospace, electronics, and medical devices.

Enhanced Performance in Electronics: In the electronics industry, high purity copper is essential for high-frequency applications, as impurities can lead to signal degradation and increased resistance.

Improved Solderability: High purity copper can improve soldering processes, leading to better joint integrity and reliability in electronic assemblies.

|

Main Size of 4N5-7N 99.995%-99.99999% high purity Pellets

|

||||

|

2*2 mm

|

3*3 mm

|

6*6 mm

|

8*10mm

|

|

|

More custom size options available!

|

||||

Founded in 2002, Ruiyuan has been in the manufacture of enamelled copper wire for 20 years.We combine the best manufacturing techniques and enamel materials to create a high-quality, best-in-class enameled wire. The enameled copper wire lies at the heart of technology we use every day – appliances, generators, transformers, turbines, coils and much more. Nowadays, Ruiyuan has the global footprint to support our partners in marketplace.

Customer Oriented,Innovation brings more Value

RUIYUAN is a solution provider, which requires us to be more professional on wires, insulation material and your applications.

Ruiyuan has a heritage of innovation, along with advancements in enameled copper wire, our company has grown through an unwavering commitment to integrity, service and responsiveness to our customers.

We look forward to continuing to grow on the basis of quality, innovation and service.

7-10 days Average delivery time.

90% European and North American customers. Such as PTR,ELSIT, STS etc.

95% Repurchase rate

99.3% Satisfaction rate. Class A supplier verified by German customer.