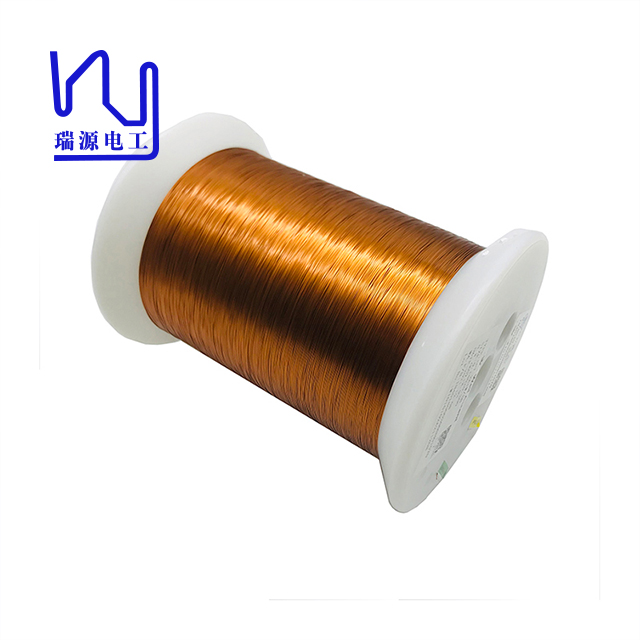

High reputation High Votage FIW Enameled Copper Wire - AIW 220 0.3mm x 0.18mm Hot Wind Enameled Flat Copper Wire – Ruiyuan

High reputation High Votage FIW Enameled Copper Wire - AIW 220 0.3mm x 0.18mm Hot Wind Enameled Flat Copper Wire – Ruiyuan Detail:

| Test Report: 0.30*0.18mm AIW Class 220℃ Hot Air Self-bonding Flat Wire | |||||

| Item | Characteristics | Standard | Test Result | ||

| 1 | Appearance | Smooth Equality | Smooth Equality | ||

| 2 | Conductor Diameter(mm) | Width | 0.300 | ±0.030 | 0.298 |

| Thickness | 0.180 | ±0.005 | 0.180 | ||

| 3 | Thickness of Insulation(mm) | Width | 0.010 | ±0.005 | 0.011 |

| Thickness | 0.010 | ±0.005 | 0.008 | ||

| 4 | Overall Diameter

(mm) |

Width | Max.0.364 | 0.326 | |

| Thickness | Max.0.219 | 0.201 | |||

| 5 | Selfbonding Layer Thickness(mm) | Min.0.002 | 0.003 | ||

| 6 | Pinhole(pcs/m) | Max ≤1 | 0 | ||

| 7 | Elongation(%) | Min ≥15 % | 30% | ||

| 8 | Flexibility and Adherence | No crack | No crack | ||

| 9 | Conductor Resistance (Ω/km at 20℃) | Max. 423.82 | 352.00 | ||

| 10 | Breakdown Voltage(kv) | Min. 0.50 | 1.65 | ||

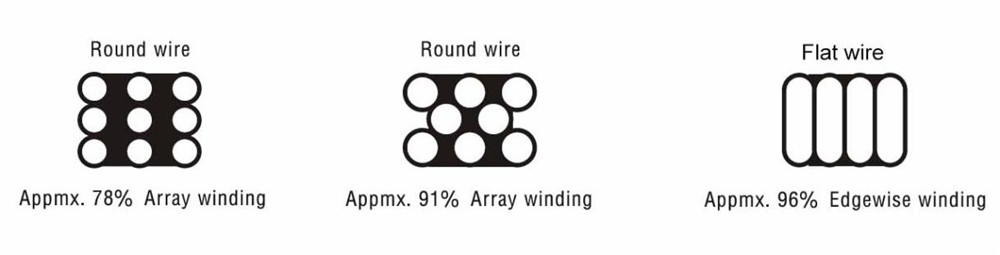

• The high space factor makes it possible to produce smaller and lighter electronic motor products that are no longer limited by coil size.

• Increased density of conductors per unit area allows for small size and high current products.

• Better heat dissipation performance and electromagnetic effect.

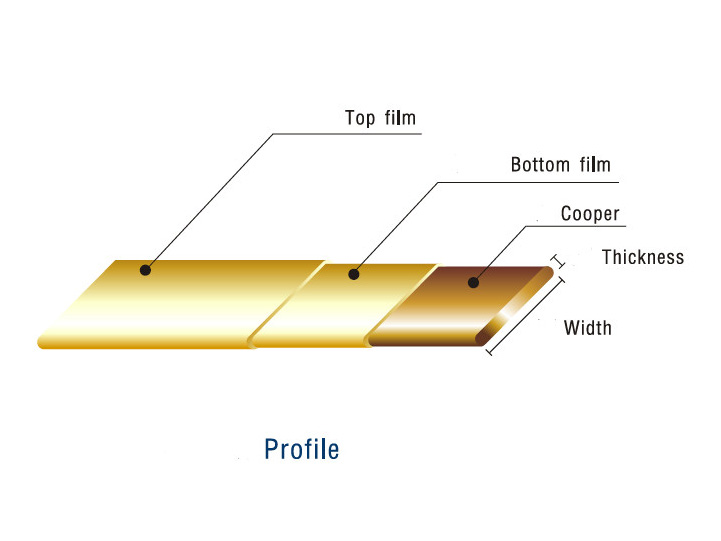

• Thickness: The minimum thickness of conductor reaches 0.09mm.

• Large width to thickness ratio: maximum width to thickness ratio is 1:15.

• Using independent innovative technology and special production process, the production of enameled copper small flat wire has better performance and heat resistance level reaches 220℃.

5G Base Station Power Supply

Aerospace

Maglev Trains

Wind Turbines

New Energy Automobile

Electronics

We produces costom rectangular enaemeled copper wire in temperature classes 155°C-240°C.

-Low MOQ

-Quick Delivery

-Top Quality

Ruiyuan attracts many outstanding technical and management talents, and our founders have built the best team in the industry with our long-term vision. We respects the values of each employee and provides them with a platform to make Ruiyuan a great place to grow a career.

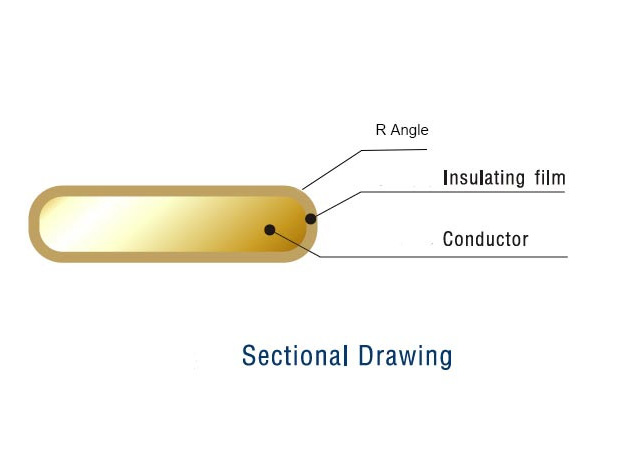

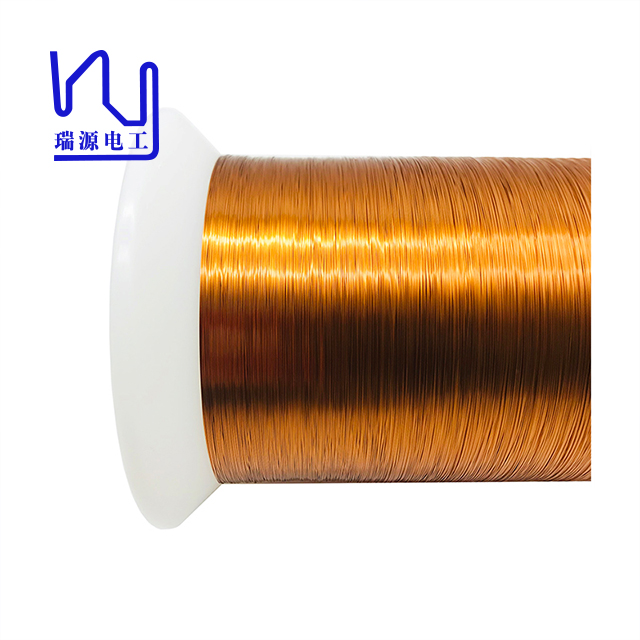

Product detail pictures:

Related Product Guide:

Our advantages are lessen charges,dynamic income team,specialized QC,sturdy factories,premium quality services for High reputation High Votage FIW Enameled Copper Wire - AIW 220 0.3mm x 0.18mm Hot Wind Enameled Flat Copper Wire – Ruiyuan , The product will supply to all over the world, such as: Burundi, Ghana, United States, We supply skilled service, prompt reply, timely delivery, excellent quality and best price to our customers. Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound items with good logistics service and economical cost. Depending on this, our products and solutions are sold very well in the countries in Africa, the Mid-East and Southeast Asia. Adhering to the business philosophy of ??customer first, forge ahead', we sincerely welcome clients from at home and abroad to cooperate with us.

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.