Manufacturer for Enameled Copper Wire For Winding Electric Motors - 0.038mm Class 155 2UEW Polyurethane Enameled Copper Wire – Ruiyuan

Manufacturer for Enameled Copper Wire For Winding Electric Motors - 0.038mm Class 155 2UEW Polyurethane Enameled Copper Wire – Ruiyuan Detail:

Main test items: pinhole test, minimum withstand voltage, tensile test, maximum resistance value.

Test method for pinhole test: Take a sample with a length of about 6m, immerse it in 0.2% saline. Drop an appropriate amount of 3% alcohol phenolphthalein solution in the saline and put 5m long sample in it. The solution is connected to the positive electrode, and the sample is connected to the negative electrode. After applying 12V DC voltage for 1 minute, check the number of pinholes produced. For enameled copper wire below 0.063mm, take a sample of about 1.5 meters in length. Only 1m long enameled wire needs to be put into the saline.

1.It features good solderability (self-soldering)and is solderable after completion of winding. Even at 360-400 degrees, the wire has great and prompt soldering property. There’ s no need to go on with mechanical stripping of enamel, contributing to increase of working efficiency

2. Under the condition of high frequency, it’ s characterized by good “Q” value.

3. Great adhesion of enamel is convenient for winding. Insulating property can remain well after winding.

4. Solvent resistance. Dyes can be used to change the color of enamel for identification. Colors that we can produce for Polyurethane enameled copper wire are red, blue, green, black and so on.

5. Our advantages: goal of “zero” pinholes after stretching. Pinholes not in compliance with standard are the main cause of short circuits for electronic devices. For our products, we set a goal to achieve “zero” pinholes after stretching by 15%.

|

Nominal Diameter |

Bare Wire Tolerance |

Resistance at 20 °C |

Minimum Insulation and Max Outer Diameter |

||||

|

Nom |

Max. |

Class 2 |

Class 3 |

||||

|

Class2/Class3 |

Class2/Class3 |

ins.thickn. |

max dia. |

ins.thickn. |

max dia. |

||

|

[mm] |

[mm] |

[Ohm/km] |

[Ohm/km] |

[mm] |

[mm] |

[mm] |

[mm] |

|

0.011 |

182500 |

||||||

|

0.012 |

157162 |

||||||

|

0.014 |

115466 |

||||||

|

0.016 |

88404 |

||||||

|

0.018 |

69850 |

||||||

|

0.019 |

62691 |

||||||

|

0.020 |

±0.002 |

56578 |

69850 |

0.003 |

0.030 |

0.002 |

0.028 |

|

0.021 |

±0.002 |

51318 |

62691 |

0.003 |

0.032 |

0.002 |

0.030 |

|

0.022 |

±0.002 |

46759 |

56578 |

0.003 |

0.033 |

0.002 |

0.031 |

|

0.023 |

±0.002 |

42781 |

51318 |

0.003 |

0.035 |

0.002 |

0.032 |

|

0.024 |

±0.002 |

39291 |

46759 |

0.003 |

0.036 |

0.002 |

0.033 |

|

0.025 |

±0.002 |

36210 |

42780 |

0.003 |

0.037 |

0.002 |

0.034 |

|

0.027 |

±0.002 |

31044 |

36210 |

0.003 |

0.040 |

0.002 |

0.037 |

|

0.028 |

±0.002 |

28867 |

33478 |

0.003 |

0.042 |

0.002 |

0.038 |

|

0.030 |

±0.002 |

25146 |

28870 |

0.003 |

0.044 |

0.002 |

0.040 |

|

0.032 |

±0.002 |

22101 |

25146 |

0.003 |

0.047 |

0.002 |

0.043 |

|

0.034 |

±0.002 |

19577 |

22101 |

0.003 |

0.049 |

0.002 |

0.045 |

|

0.036 |

±0.002 |

17462 |

19577 |

0.003 |

0.052 |

0.002 |

0.048 |

|

0.038 |

±0.002 |

15673 |

17462 |

0.003 |

0.054 |

0.002 |

0.050 |

|

0.040 |

±0.002 |

14145 |

15670 |

0.003 |

0.056 |

0.002 |

0.052 |

|

Nominal Diameter |

Bare Wire Tolerance |

Elongation acc. to JIS |

Breakdown Voltage acc. to JIS |

|

|

Class 2 |

Class 3 |

|||

| (mm) | Class2/Class3 |

min |

min |

min |

| [mm] |

[%] |

[V] |

[V] |

|

| 0.011 | ||||

| 0.012 | ||||

| 0.014 | ||||

| 0.016 | ||||

| 0.018 | ||||

| 0.019 | ||||

| 0.020 | ±0.002 |

3 |

100 |

40 |

| 0.021 | ±0.002 |

5 |

120 |

60 |

| 0.022 | ±0.002 |

5 |

120 |

60 |

| 0.023 | ±0.002 |

5 |

120 |

60 |

| 0.024 | ±0.002 |

5 |

120 |

60 |

| 0.025 | ±0.002 |

5 |

120 |

60 |

| 0.027 | ±0.002 |

5 |

150 |

70 |

| 0.028 | ±0.002 |

5 |

150 |

70 |

| 0.030 | ±0.002 |

5 |

150 |

70 |

| 0.032 | ±0.002 |

7 |

200 |

100 |

| 0.034 | ±0.002 |

7 |

200 |

100 |

| 0.036 | ±0.002 |

7 |

200 |

100 |

| 0.038 | ±0.002 |

7 |

200 |

100 |

| 0.040 | ±0.002 |

7 |

200 |

100 |

Transformer

Motor

Ignition coil

Voice Coil

Electrics

Relay

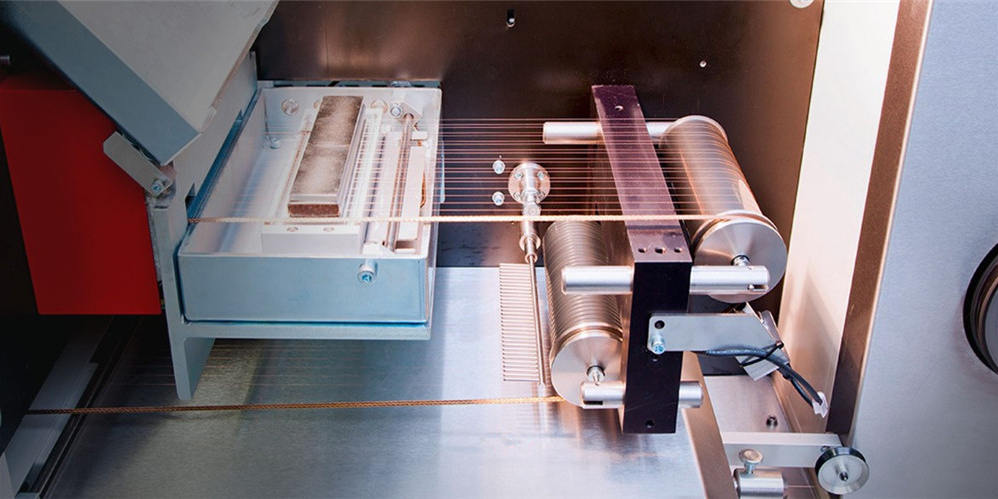

Drawing

Paint

Annealing

Baking

Cooling

Customer Oriented,Innovation brings more Value

RUIYUAN is a solution provider, which requires us to be more professional on wires, insulation material and your applications.

Ruiyuan has a heritage of innovation, along with advancements in enameled copper wire, our company has grown through an unwavering commitment to integrity, service and responsiveness to our customers.

We look forward to continuing to grow on the basis of quality, innovation and service.

7-10 days Average delivery time.

90% European and North American customers. Such as PTR,ELSIT, STS etc.

95% Repurchase rate

99.3% Satisfaction rate. Class A supplier verified by German customer.

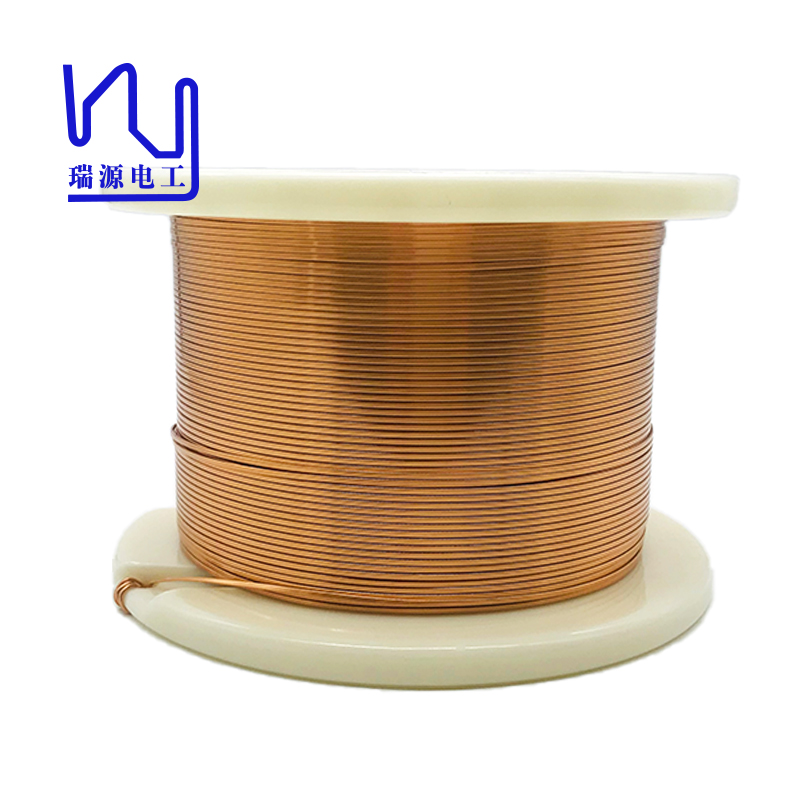

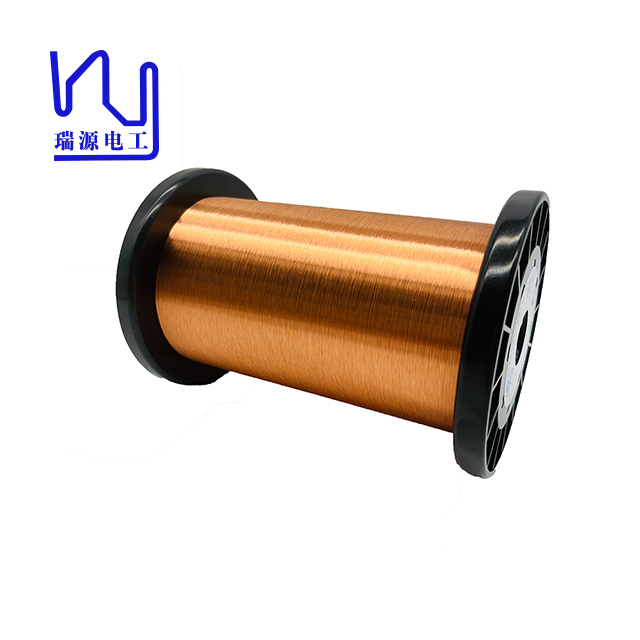

Product detail pictures:

Related Product Guide:

We're commitment to offer you the aggressive cost ,superb products and solutions top quality, too as fast delivery for Manufacturer for Enameled Copper Wire For Winding Electric Motors - 0.038mm Class 155 2UEW Polyurethane Enameled Copper Wire – Ruiyuan , The product will supply to all over the world, such as: Florence, Lisbon, Ottawa, We have constructed strong and long co-operation relationship with an enormous quantity of companies within this business overseas. Immediate and specialist after-sale service supplied by our consultant group has happy our buyers. Detailed Info and parameters from the merchandise will probably be sent to you for any thorough acknowledge. Free samples may be delivered and company check out to our corporation. n Portugal for negotiation is constantly welcome. Hope to get inquiries type you and construct a long-term co-operation partnership.

This is a reputable company, they have a high level of business management, good quality product and service, every cooperation is assured and delighted!