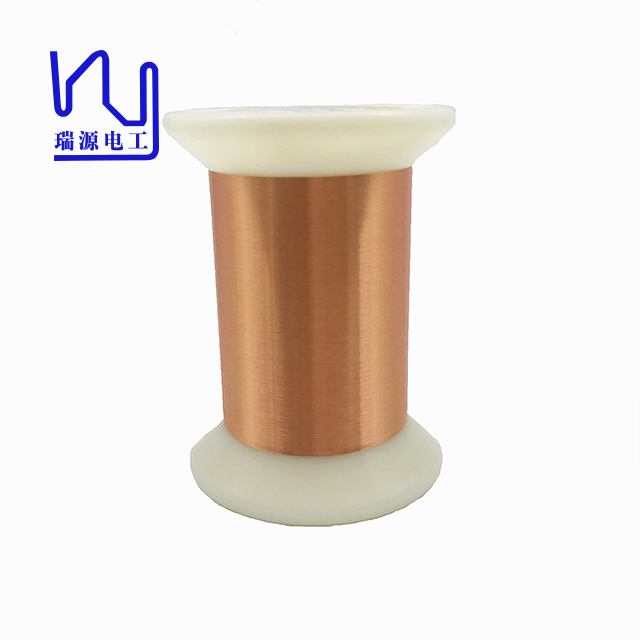

Manufacturer for Enameled Copper Wire For Winding Electric Motors - HCCA 2KS-AH 0.04mm Self Bonding Enameled Copper Wire f – Ruiyuan

Manufacturer for Enameled Copper Wire For Winding Electric Motors - HCCA 2KS-AH 0.04mm Self Bonding Enameled Copper Wire f – Ruiyuan Detail:

Both pure copper and copper clad with aluminum can both be used as conductor for wire when there’ s different needs of tone quality. Study shows that higher purity of copper is beneficial to improve sound quality. It can be seen that pure 4N (99.99%) copper is usually adopted in the market. Copper coated aluminum conductor self-adhesive wire conforms to requirement of improving utilization rate of wire without affecting sound quality (high-frequency voice coil). Bond coat of the wire can be activated by two methods of hot air and solvent. This wire is preferred by most customers due to its convenient process to shape and low cost. Diameter of this wire is relatively thin.

After an exploration of RUIYUAN R & D department for a long time, we realized that requirements for environmental protection and energy saving are increasing. Hence it is more practical to develop a new type of self-adhesive enameled wire that can withstand high temperature and is bondable at low temperature.

Our newly developed hot wind bonded enameled copper wire of low temperature curing and high-temperature application and solvent bonding wire that can shorten bonding time is just designed to meet the needs of saving energy. The experimental results show that our solvent bonding magnet wire produced by the new formula has good performance and properties at the curing condition of 180℃×10 ~ 15min when new type hot-air self-adhesive enamelled copper wire is environment-friendly as well.

Voice coil production requiring high-speed, seismic and tensile resistant winding puts forward new requirements for conductors of self-adhesive magnet wire. The tensile strength of copper conductor with suitable alloy can be increased by about 20 ~ 30% compared with that of ordinary copper conductor, especially for fine self-adhesive wire. Self-adhesive magnet wires with alloy conductor and high tension resistance are becoming popular in the production of high-end voice coils. In a word, developing one-of-a-kind bond coat and bonding magnet wire with high-frequency audio transmission, light weight, high strength and novel conductors for high-end voice coils has become Ruiyuan’ s future direction.

Technical Parameter Table Of Enameled Stranded Wire

|

Test Item |

Unit |

Standard Value |

Reality Value |

||

|

Conductor dimensions |

mm |

0.040±0.001 |

0.040 |

0.040 |

0.040 |

|

(Basecoat dimensions) Overall dimensions |

mm |

Max. 0.053 |

0.0524 |

0.0524 |

0.0524 |

|

Insulation Film Thickness |

mm |

Min0.002 |

0.003 |

0.003 |

0.003 |

|

Bonding Film Thickness |

mm |

Min0.002 |

0.003 |

0.003 |

0.003 |

|

(50V/30m) Continuity of covering |

pcs. |

Max.60 |

Max.0 |

||

|

Adherence |

No crack |

Good |

|||

|

Breakdown Voltage |

V |

Min.475 |

Min.1302 |

||

|

Resistance to Softening (Cut Through) |

℃ |

Continue 2 times pass |

200℃/Good |

||

|

(390℃±5℃) Solder test |

s |

Max 2 |

Max 1.5 |

||

|

Bonding Strength |

g |

Min.5 |

11 |

||

|

(20℃) Electrical Resistance |

Ω/m |

21.22-22.08 |

21.67 |

21.67 |

21.67 |

|

Elongation |

% |

Min.4 |

8 |

8 |

8 |

|

Surface appearance |

Smooth coloury |

Good |

|||

Transformer

Motor

Ignition coil

Voice Coil

Electrics

Relay

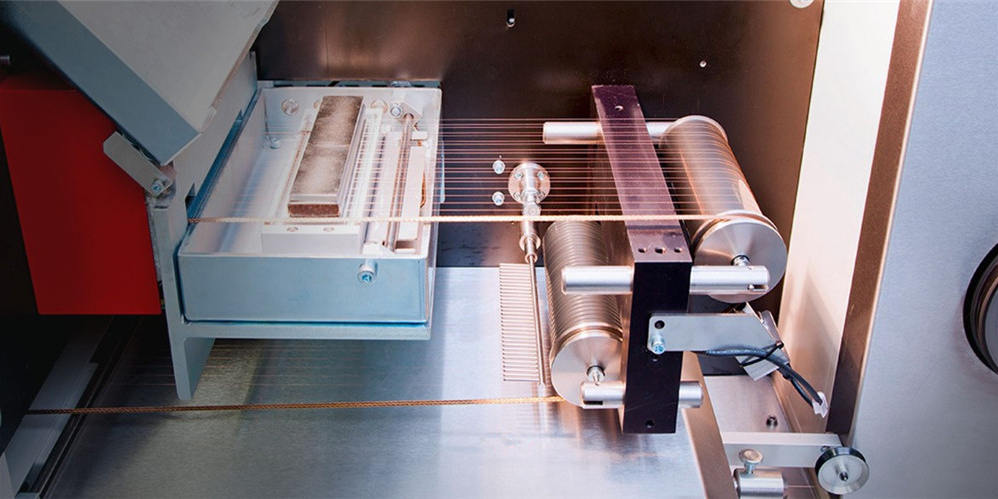

Drawing

Paint

Annealing

Baking

Cooling

Customer Oriented,Innovation brings more Value

RUIYUAN is a solution provider, which requires us to be more professional on wires, insulation material and your applications.

Ruiyuan has a heritage of innovation, along with advancements in enameled copper wire, our company has grown through an unwavering commitment to integrity, service and responsiveness to our customers.

We look forward to continuing to grow on the basis of quality, innovation and service.

7-10 days Average delivery time.

90% European and North American customers. Such as PTR,ELSIT, STS etc.

95% Repurchase rate

99.3% Satisfaction rate. Class A supplier verified by German customer.

Product detail pictures:

Related Product Guide:

The shopper satisfaction is our primary focus on. We uphold a consistent level of professionalism, quality, credibility and repair for Manufacturer for Enameled Copper Wire For Winding Electric Motors - HCCA 2KS-AH 0.04mm Self Bonding Enameled Copper Wire f – Ruiyuan , The product will supply to all over the world, such as: Amman, Miami, Algeria, We firmly think that we have the full capability to present you contented merchandise. Wish to collect concerns within you and build a new long-term synergy romantic relationship. We all significantly promise:Csame excellent, better selling price; exact selling price, better quality.

It's really lucky to find such a professional and responsible manufacturer, the product quality is good and delivery is timely, very nice.