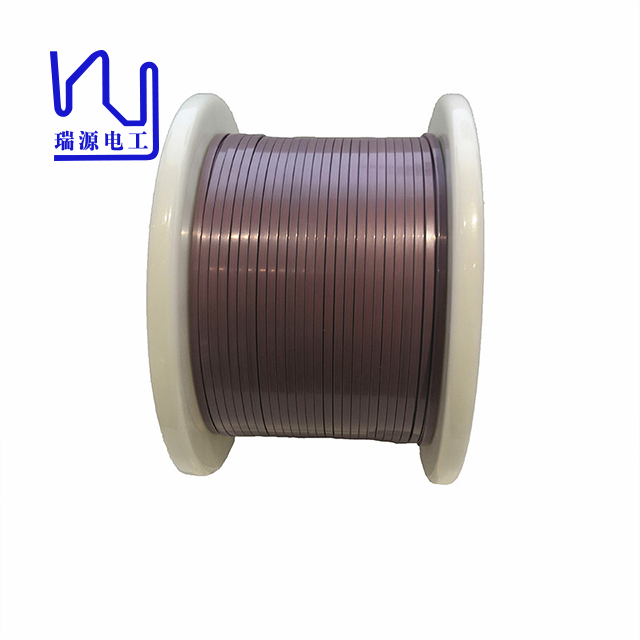

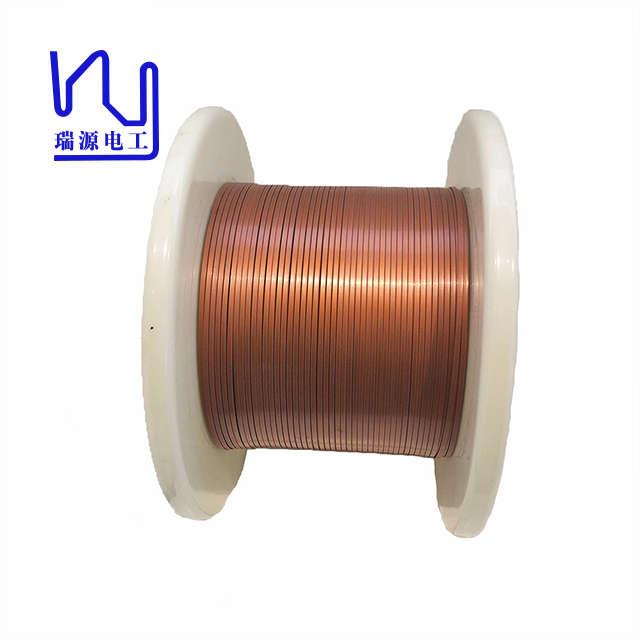

Manufacturer for Flat Copper Electric Motor Winding Wire - Custom PEEK wire, rectangular enameled copper wire – Ruiyuan

Manufacturer for Flat Copper Electric Motor Winding Wire - Custom PEEK wire, rectangular enameled copper wire – Ruiyuan Detail:

PEEK its full name Polyetheretherketone, is a semi-crystalline, high-performance,

rigid engineering thermoplastic material with various beneficial properties and an excellent resistance to cruel chemicals.

Remarkable mechanical properties, resistance to wear, fatigue, and high temperature up to 260°C

One of the most resilient and smoothest material make PEEK rectangular wire mostly utilized in industries like oil and gas, aerospace, automotive, electrical, biomedical, and semi-conductor applications

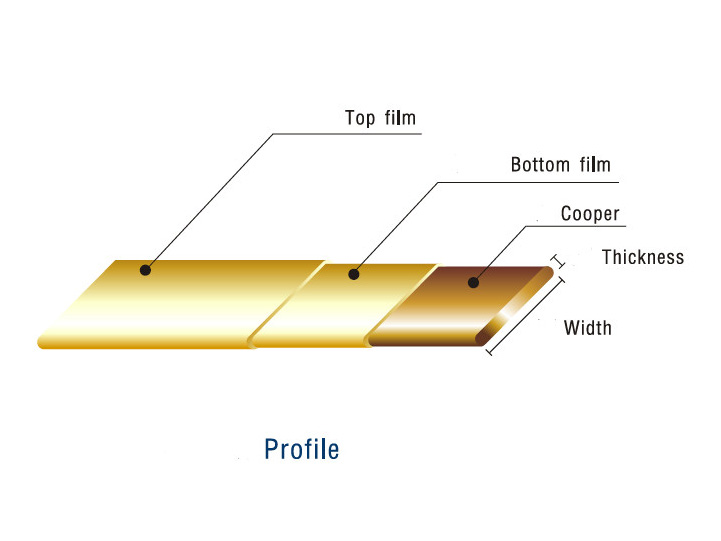

Profile of PEEK rectangular wire

Finished Product

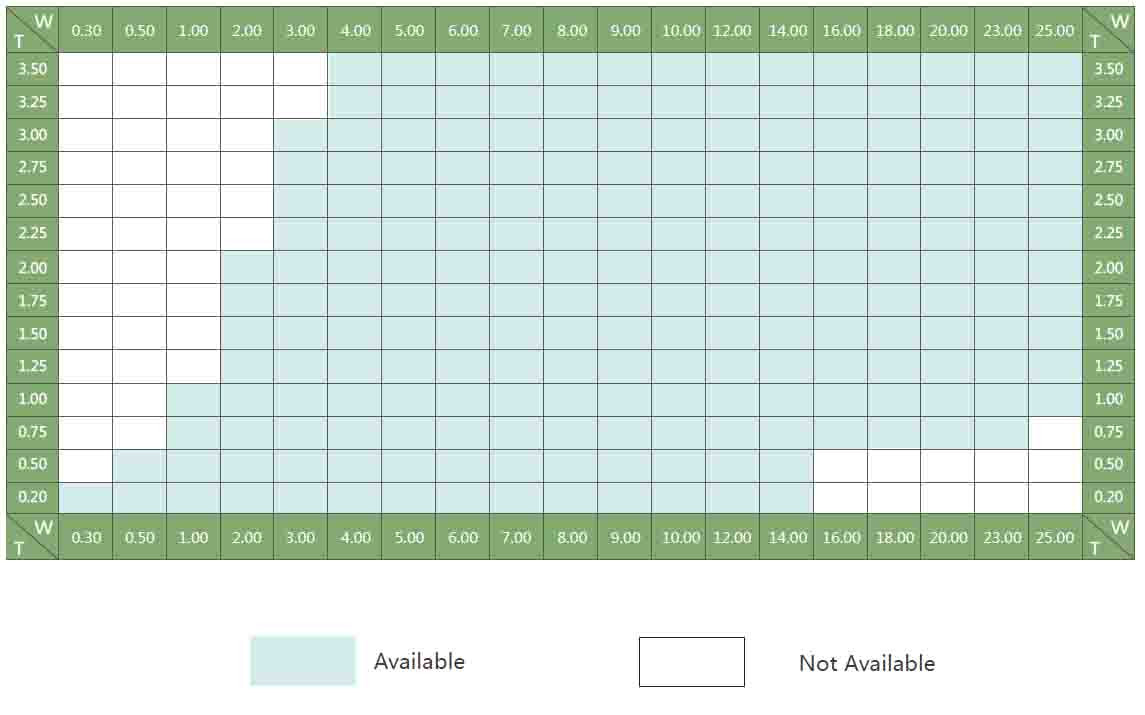

| Width(mm) | Thickness(mm) | T/W ratio |

| 0.3-25mm | 0.2-3.5mm | 1:1-1:30 |

|

Thickness Grade |

PEEK Thickness |

Voltage(V) |

PDIV(V) |

|

Grade 0 |

145μm |

>20000 |

>1500 |

|

Grade 1 |

95-145μm |

>15000 |

>1200 |

|

Grade 2 |

45-95μm |

>12000 |

>1000 |

|

Grade 3 |

20-45μm |

>5000 |

>700 |

1.High Thermal Class: Continuous operating temperature over 260℃

2.Remarkable wear resistance and resilient

3.Corona resistance, low dielectric constant

4.Excellent resistance to cruel chemicals. Like Lubricating oil, ATF oil, impregnating paint, epoxy paint

5.PEEK boasts one of the best flame resistance properties of most other thermoplastics with the size of 1.45mm; it doesn’t need any flame retardants.

6.Best Environment protect material. All the PEEK grades are compliant with FDA regulation 21 CFR 177.2415. So it is safe and secure for all most all the applications. The copper wire is compliant with RoHS and REACH

Driving motors,

Generators for new energy vehicles

Traction motors for aerospace, wind energy and rail transit

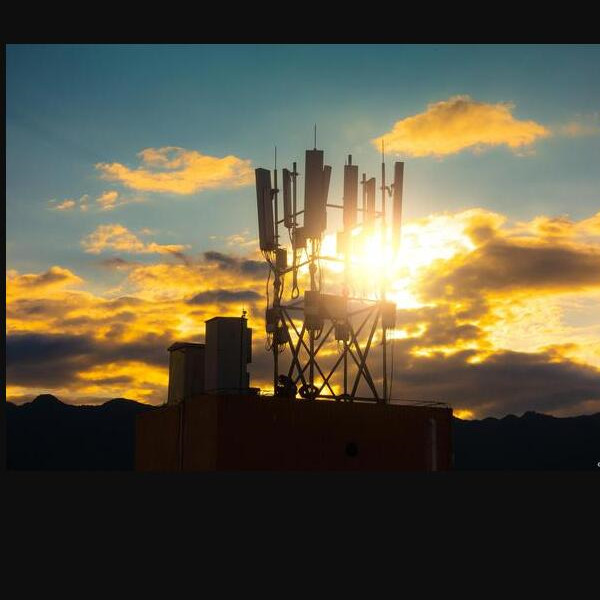

5G Base Station Power Supply

Aerospace

Maglev Trains

Wind Turbines

New Energy Automobile

Electronics

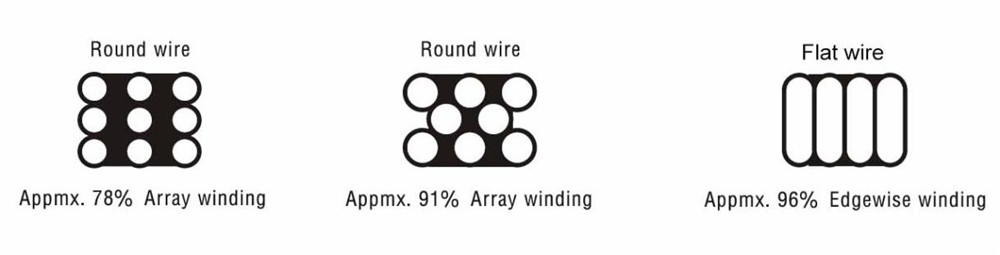

We produces costom rectangular enaemeled copper wire in temperature classes 155°C-240°C.

-Low MOQ

-Quick Delivery

-Top Quality

Ruiyuan attracts many outstanding technical and management talents, and our founders have built the best team in the industry with our long-term vision. We respects the values of each employee and provides them with a platform to make Ruiyuan a great place to grow a career.

Product detail pictures:

Related Product Guide:

We take customer-friendly, quality-oriented, integrative, innovative as objectives. Truth and honesty is our administration ideal for Manufacturer for Flat Copper Electric Motor Winding Wire - Custom PEEK wire, rectangular enameled copper wire – Ruiyuan , The product will supply to all over the world, such as: Houston, Canada, Frankfurt, Besides there are also experienced production and management , advanced production equipment to assure our quality and delivery time , our company pursues the principle of good faith, high-quality and high-efficiency. We guarantee that our company will try our best to reduce customer purchase cost, shorten the period of purchase, stable solutions quality, increase customers' satisfaction and achieve win-win situation .

The goods we received and the sample sales staff display to us have the same quality, it is really a creditable manufacturer.