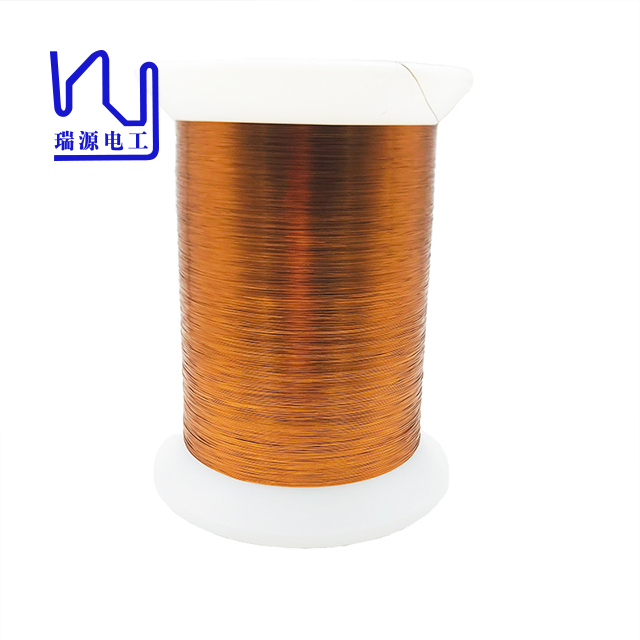

New Arrival China Custom UEWH 180 Flat Enameled Copper Wire For Motor/Transformer Winding - AIW 220 0.3mm x 0.18mm Hot Wind Enameled Flat Copper Wire – Ruiyuan

New Arrival China Custom UEWH 180 Flat Enameled Copper Wire For Motor/Transformer Winding - AIW 220 0.3mm x 0.18mm Hot Wind Enameled Flat Copper Wire – Ruiyuan Detail:

| Test Report: 0.30*0.18mm AIW Class 220℃ Hot Air Self-bonding Flat Wire | |||||

| Item | Characteristics | Standard | Test Result | ||

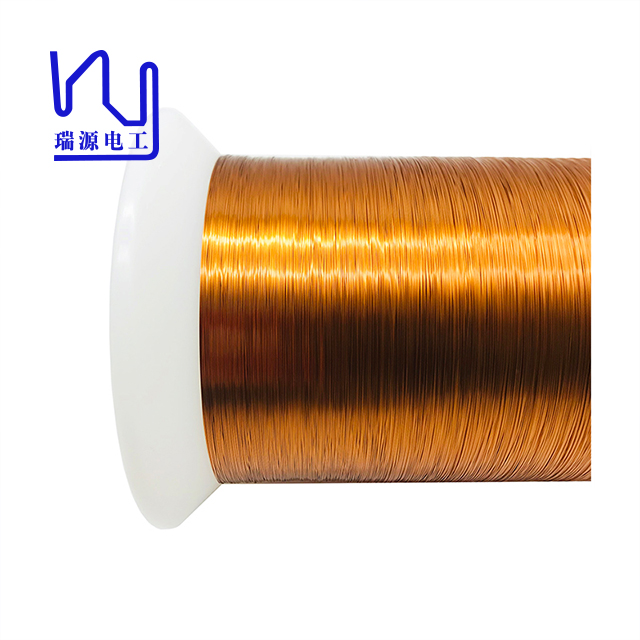

| 1 | Appearance | Smooth Equality | Smooth Equality | ||

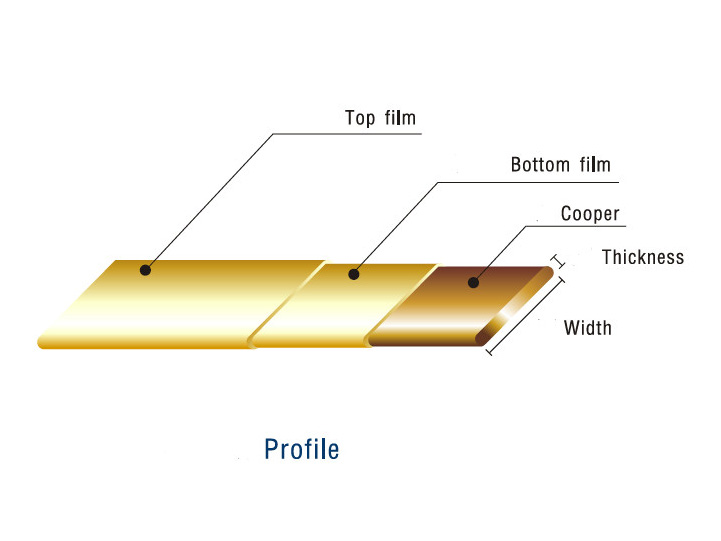

| 2 | Conductor Diameter(mm) | Width | 0.300 | ±0.030 | 0.298 |

| Thickness | 0.180 | ±0.005 | 0.180 | ||

| 3 | Thickness of Insulation(mm) | Width | 0.010 | ±0.005 | 0.011 |

| Thickness | 0.010 | ±0.005 | 0.008 | ||

| 4 | Overall Diameter

(mm) |

Width | Max.0.364 | 0.326 | |

| Thickness | Max.0.219 | 0.201 | |||

| 5 | Selfbonding Layer Thickness(mm) | Min.0.002 | 0.003 | ||

| 6 | Pinhole(pcs/m) | Max ≤1 | 0 | ||

| 7 | Elongation(%) | Min ≥15 % | 30% | ||

| 8 | Flexibility and Adherence | No crack | No crack | ||

| 9 | Conductor Resistance (Ω/km at 20℃) | Max. 423.82 | 352.00 | ||

| 10 | Breakdown Voltage(kv) | Min. 0.50 | 1.65 | ||

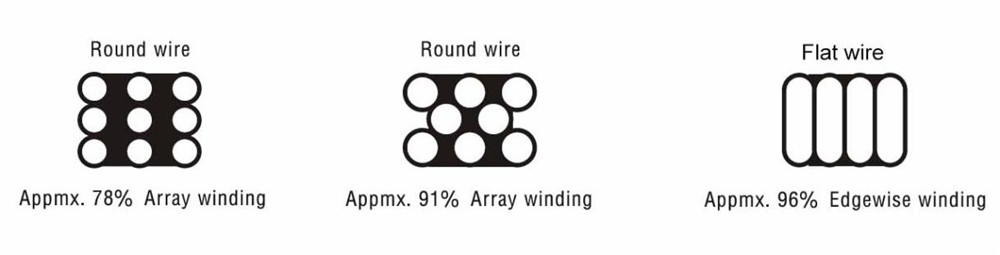

• The high space factor makes it possible to produce smaller and lighter electronic motor products that are no longer limited by coil size.

• Increased density of conductors per unit area allows for small size and high current products.

• Better heat dissipation performance and electromagnetic effect.

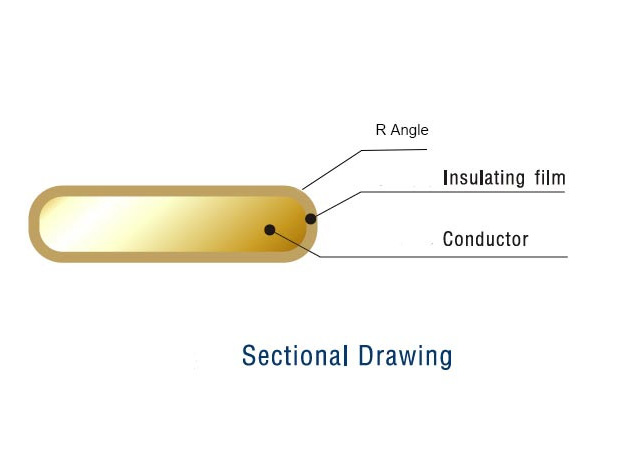

• Thickness: The minimum thickness of conductor reaches 0.09mm.

• Large width to thickness ratio: maximum width to thickness ratio is 1:15.

• Using independent innovative technology and special production process, the production of enameled copper small flat wire has better performance and heat resistance level reaches 220℃.

5G Base Station Power Supply

Aerospace

Maglev Trains

Wind Turbines

New Energy Automobile

Electronics

We produces costom rectangular enaemeled copper wire in temperature classes 155°C-240°C.

-Low MOQ

-Quick Delivery

-Top Quality

Ruiyuan attracts many outstanding technical and management talents, and our founders have built the best team in the industry with our long-term vision. We respects the values of each employee and provides them with a platform to make Ruiyuan a great place to grow a career.

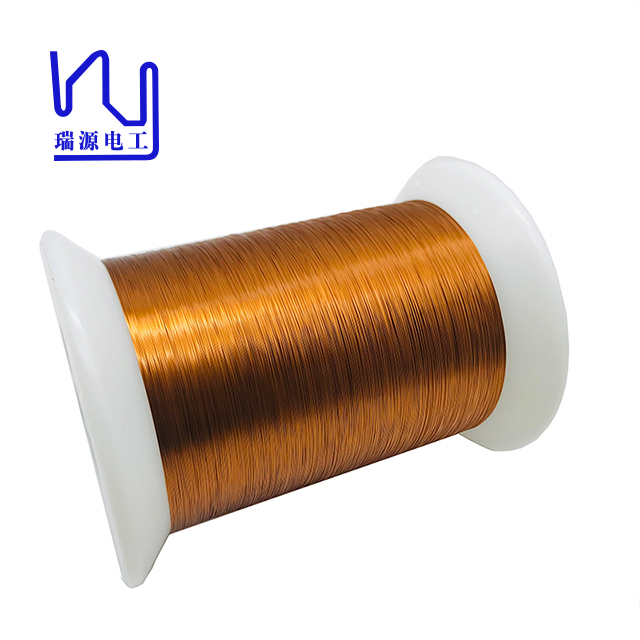

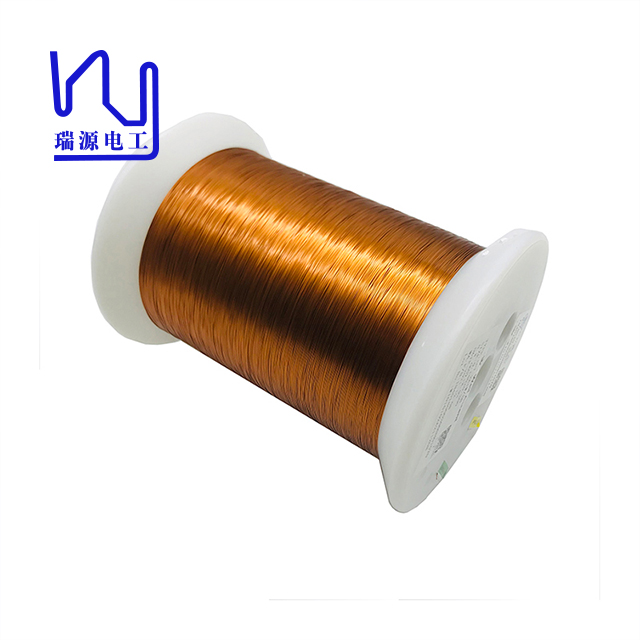

Product detail pictures:

Related Product Guide:

We've one of the most innovative manufacturing devices, experienced and qualified engineers and workers, recognized good quality handle systems and also a friendly experienced income team pre/after-sales support for New Arrival China Custom UEWH 180 Flat Enameled Copper Wire For Motor/Transformer Winding - AIW 220 0.3mm x 0.18mm Hot Wind Enameled Flat Copper Wire – Ruiyuan , The product will supply to all over the world, such as: America, Italy, Bahrain, We've got constantly insisted on the evolution of solutions, spent good funds and human resource in technological upgrading, and facilitate production improvement, meeting the wants of prospects from all countries and regions.

The customer service staff's answer is very meticulous, the most important is that the product quality is very good, and packaged carefully, shipped quickly!