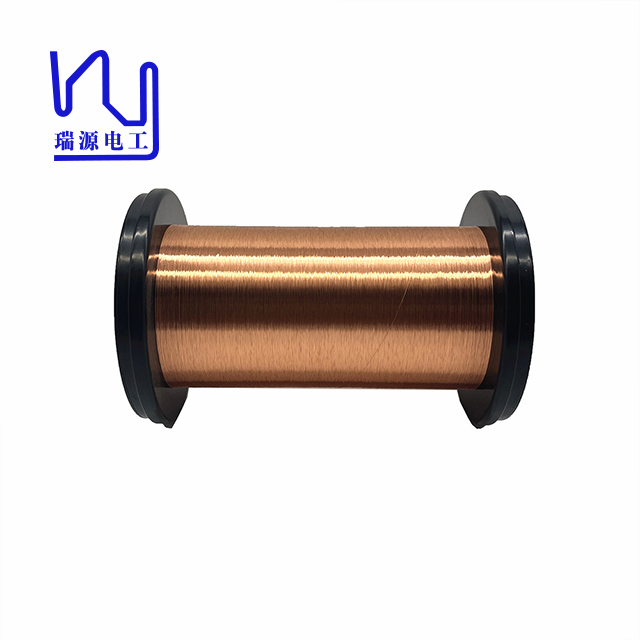

New Arrival China High Temperature Winding Wire 32 Awg - 0.071mm Enameled Copper Wire for Electric Motor Winding – Ruiyuan

New Arrival China High Temperature Winding Wire 32 Awg - 0.071mm Enameled Copper Wire for Electric Motor Winding – Ruiyuan Detail:

Enameled Copper Wire for Electric Motor produced by our company has good performance to resist high heat, abrasion, and corona. After years of practice from R&D to mass production, we develop our own patent technical solutions which is metal conductor(copper wire) is enamelled with a basic heat-resistant layer of polyesterimide covered with another layer of polyamide-imide resin. This structure of compound coating over copper wire contributes to excellent properties of our enameled copper wire, including higher thermal class, good corona resistance and enamel protection. Thus for applications that require high temperature resistance, such as high temperature motors, load motors, air conditioner compressors, refrigerator compressors, water dispensers. and other products, our enameled copper wire is the best solution.

Modified polyester or polyesterimide with thermal class 200 as base coat not only increases heat resistance but also maintains scratch resistant property that class 180 enameled copper wire have. Polyamide-imide resin with a temperature rating of 220 featuring solvent resistance, excellent breakdown voltage performance and smooth surface is used as extra coat so that thermal class, corona resistance, enamel protection and other properties of the enameled copper wire are improved. All these properties makes our enameled copper wire with thermal class 200 suitable for use to high temperature motors, load motors, air conditioner compressors, refrigerator compressors, water dispensers and other products.

Besides, coats of our class 200 enameled copper wire: the weight of modified polyester or polyesterimide resin accounts for 70% to 80%, while polyamideimide resin coat accounts for 20% to 30%. Since unit cost of polyamide-imide resin is generally 160% of that of polyesterimide, a small proportion of polyamideimide cuts the cost and also ensures compound coating. As it is difficult to achieve smooth surface, we need to make technological adjustment to manufacture, such as increase of the cooling air volume to keep it well coated and two rows of paint roller for compound coating.

| Diameter(mm) |

Overall diameter |

|||||

| Grade 1 | Grade 2 | Grade 3 | ||||

|

min |

max |

min |

max |

min |

max |

|

|

[mm] |

[mm] |

[mm] |

[mm] |

[mm] |

[mm] |

|

|

0.020 |

0.022 |

0.024 |

0.025 |

0.027 |

0.028 |

0.03 |

|

0.028 |

0.031 |

0.034 |

0.035 |

0.038 |

0.039 |

0.042 |

|

0.032 |

0.035 |

0.039 |

0.04 |

0.043 |

0.044 |

0.047 |

|

0.040 |

0.044 |

0.049 |

0.05 |

0.054 |

0.055 |

0.058 |

|

0.045 |

0.05 |

0.055 |

0.056 |

0.061 |

0.062 |

0.066 |

|

0.050 |

0.055 |

0.06 |

0.061 |

0.066 |

0.067 |

0.07 |

|

0.056 |

0.062 |

0.067 |

0.068 |

0.074 |

0.075 |

0.079 |

|

0.060 |

0.066 |

0.072 |

0.073 |

0.079 |

0.08 |

0.085 |

|

0.071 |

0.078 |

0.084 |

0.085 |

0.091 |

0.092 |

0.096 |

|

0.080 |

0.087 |

0.094 |

0.095 |

0.101 |

0.102 |

0.108 |

|

0.090 |

0.098 |

0.105 |

0.106 |

0.113 |

0.114 |

0.12 |

|

0.100 |

0.108 |

0.117 |

0.118 |

0.125 |

0.126 |

0.132 |

|

0.120 |

0.13 |

0.138 |

0.139 |

0.148 |

0.149 |

0.157 |

|

0.150 |

0.162 |

0.171 |

0.172 |

0.182 |

0.183 |

0.193 |

|

0.180 |

0.193 |

0.204 |

0.205 |

0.217 |

0.218 |

0.229 |

|

0.200 |

0.214 |

0.226 |

0.227 |

0.239 |

0.24 |

0.252 |

|

0.450 |

0.472 |

0.491 |

0.492 |

0.513 |

0.514 |

0.533 |

|

0.500 |

0.524 |

0.544 |

0.545 |

0.566 |

0.567 |

0.587 |

Transformer

Motor

Ignition coil

Voice Coil

Electrics

Relay

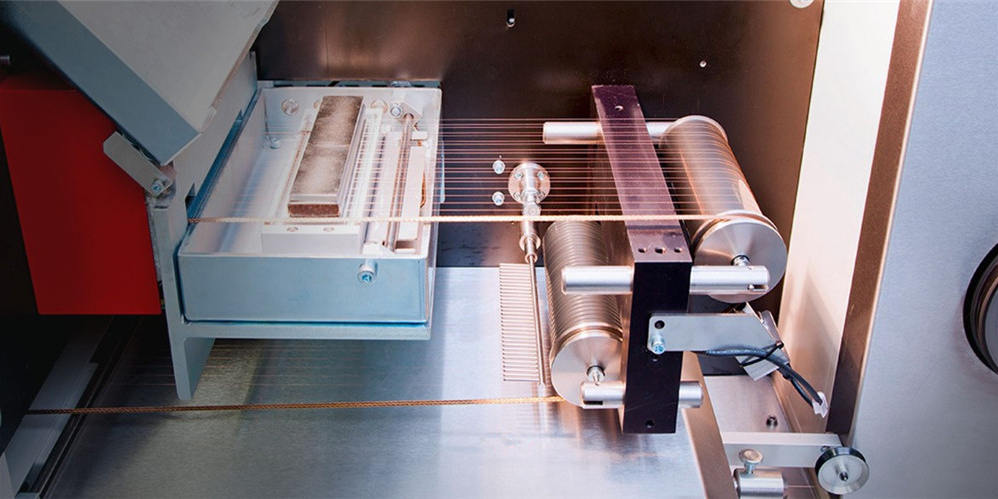

Drawing

Paint

Annealing

Baking

Cooling

Customer Oriented,Innovation brings more Value

RUIYUAN is a solution provider, which requires us to be more professional on wires, insulation material and your applications.

Ruiyuan has a heritage of innovation, along with advancements in enameled copper wire, our company has grown through an unwavering commitment to integrity, service and responsiveness to our customers.

We look forward to continuing to grow on the basis of quality, innovation and service.

7-10 days Average delivery time.

90% European and North American customers. Such as PTR,ELSIT, STS etc.

95% Repurchase rate

99.3% Satisfaction rate. Class A supplier verified by German customer.

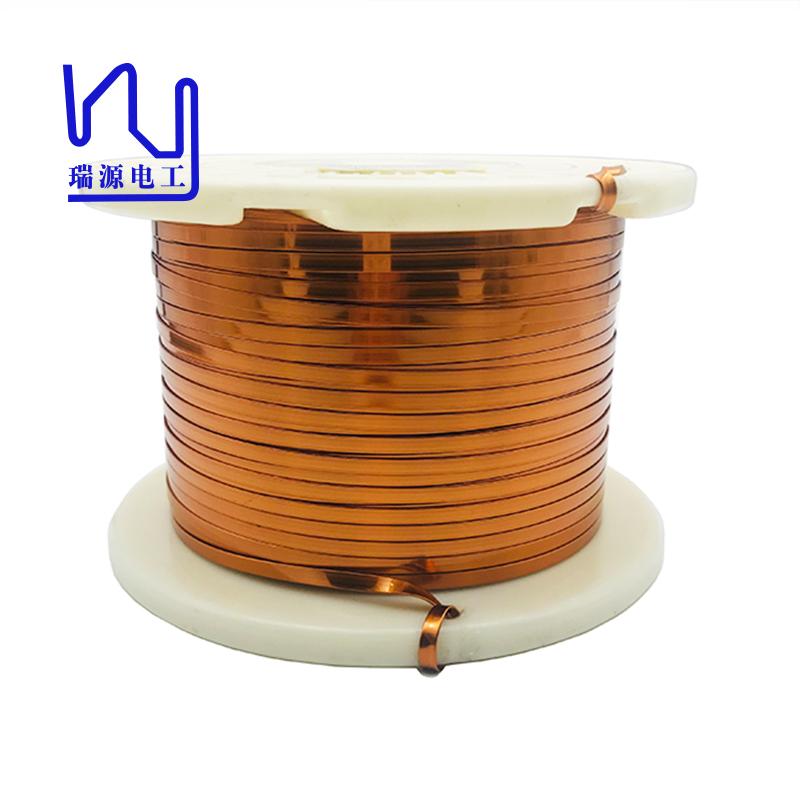

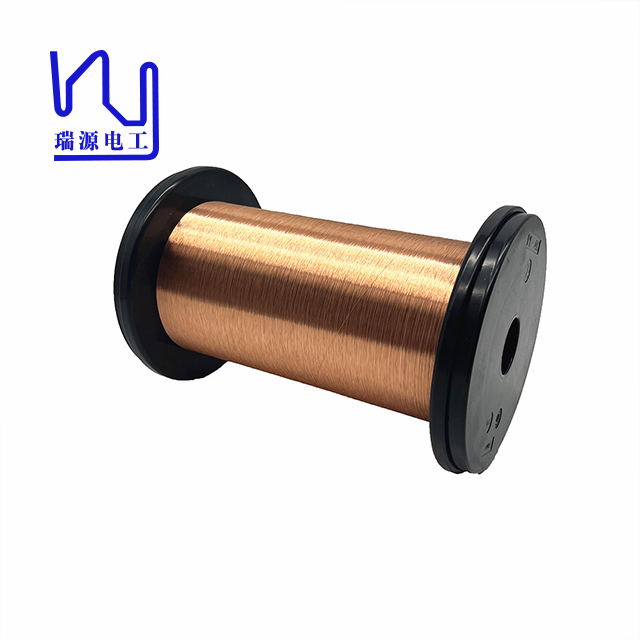

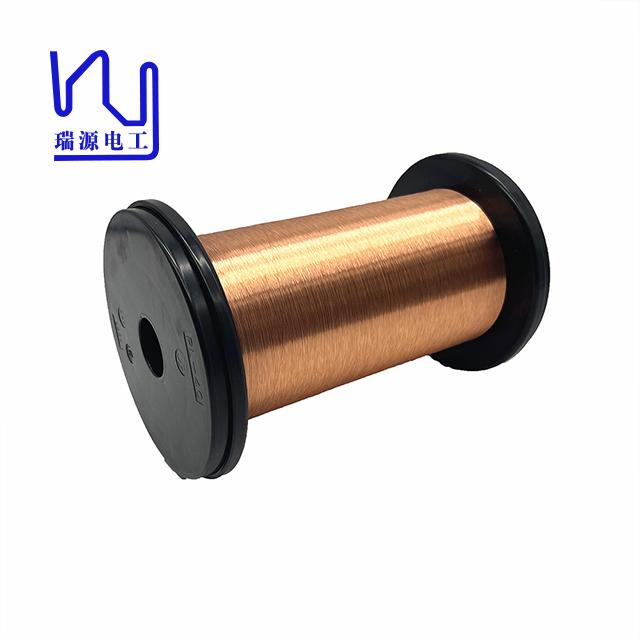

Product detail pictures:

Related Product Guide:

We strive for excellence, services the customers, hopes to be the top cooperation team and dominator business for personnel, suppliers and prospects, realizes benefit share and continual promotion for New Arrival China High Temperature Winding Wire 32 Awg - 0.071mm Enameled Copper Wire for Electric Motor Winding – Ruiyuan , The product will supply to all over the world, such as: Zurich, Greece, San Diego, With the goal of zero defect. To care for the environment, and social returns, care employee social responsibility as own duty. We welcome friends from all over the world to visit and guide us so that we can achieve the win-win goal together.

The after-sale warranty service is timely and thoughtful, encounter problems can be resolved very quickly, we feel reliable and secure.