Recently, the General Manger of Jiangxi Zeng Chang Metal Co.,Ltd took a special trip to Tianjin Rvyuan Electric Material Co.,Ltd, bearing the hope for deep technical communication and business discussion. In the meeting, the two groups focus on the discussion about the application in the field of electronic heat dissipation from extra-fine copper wire as well as the exporting foresight of special magnet wires , which laid a solid foundation for potential cooperation.

Mr. Zeng walked us through his core product : the extra-fine bare copper wire with a diameter of just 0.03mm. The bare copper wire goes through tight production steps like drawing and annealing, giving it really high ductility and electrical conductivity.

It’s mainly used for weaving high-density copper mesh, which is a key material in smartphone heat dissipation modules. Mr. Zeng added: “Here is how we make it: first, we weave the bare copper wire into a mesh and fix the nodes with laser welding. Then we bond and press it with a grapheme heat-conducting layer, and finish off with vacuum coating to boost surface heat transfer. This composite heat sink spreads the chip’s heat evenly across the phone body, upping heat dissipation efficiency by as much as 30%.”

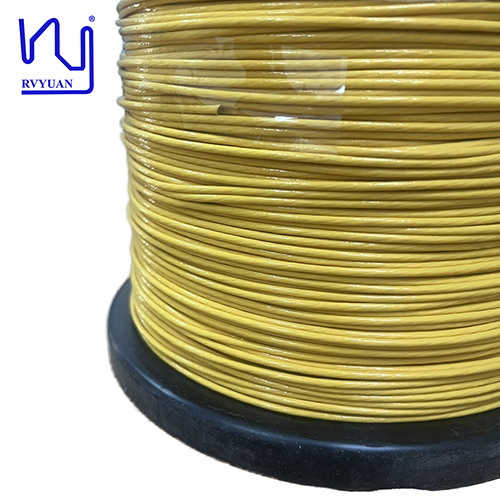

General Manager Mr. Yuan from Rvyuan fully recognized this and shared an introduction to our company. As an exporter of magnet copper wire with over 20 years of experience, we’re now focusing heavily on expanding our ETFE wire business in the South Asian market.

Mr. Yuan highlighted that our ETFE enameled wire stands out for its excellent high-temperature resistance . The ETFE enameled copper wire can operate long-term at up to 180°C. Its dielectric loss tangent is below 0.0005, which means it maintains great electrical stability even in high-frequency environments. On top of that, it has strong chemical corrosion resistance and mechanical strength, so the insulation stays intact even in South Asia’s hot and humid climates. That’s why it’s a perfect fit for the strict demands of power equipment and the new energy sector there.

This technical exchange not only showcased Chinese manufacturing’s breakthroughs in niche sectors, but also highlighted the value of collaborative innovation across the upstream and downstream of the industrial chain. Both sides noted they’ll follow up with sample testing to jointly explore ways to integrate electronic heat dissipation technologies with special electromagnetic wire solutions.

Post time: Dec-15-2025