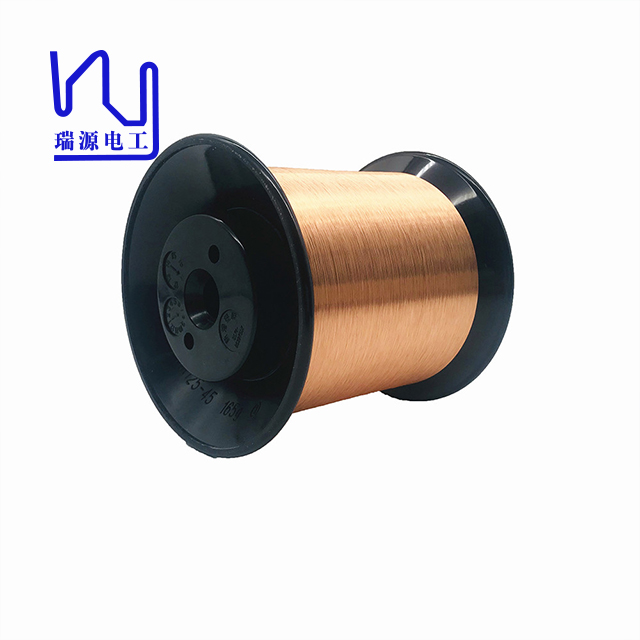

OEM/ODM Supplier Square Magnet Wire - HTW High Tension Enameled Copper Wire – Ruiyuan

OEM/ODM Supplier Square Magnet Wire - HTW High Tension Enameled Copper Wire – Ruiyuan Detail:

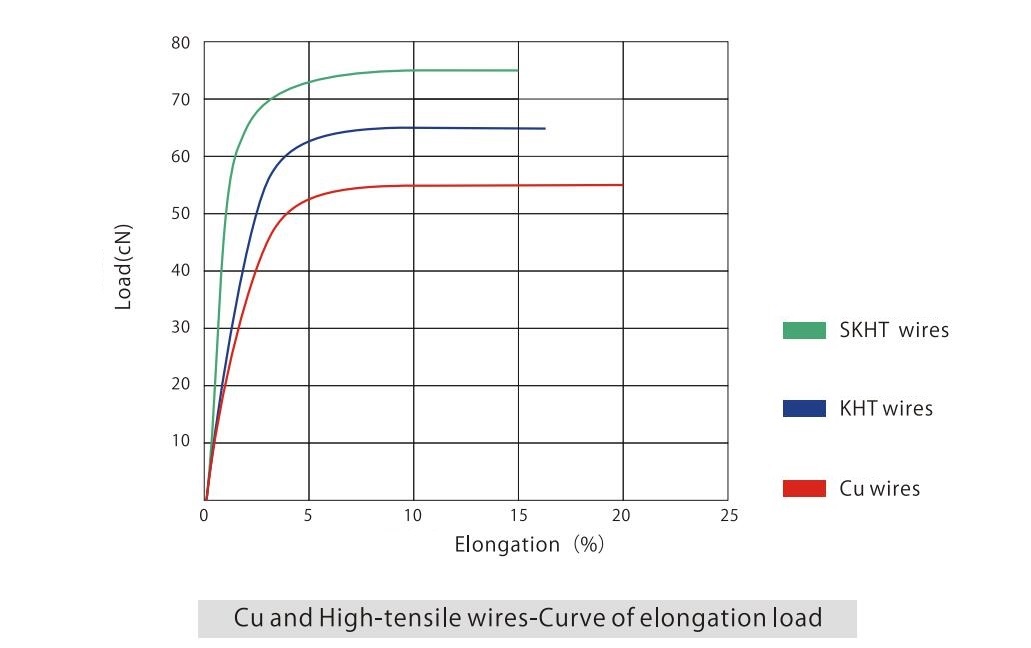

As electronic products tend to be small-sized, there’ re higher requirements for super fine magnet wires. Not only light weight and thin diameter is required, but also increase of power. We need to take the property of fine wires that are easily broken during the winding. Taking into account other characteristics, copper alloys combined with other components is used to improve tension and for the purpose of that decrease in electrical conductivity is not too large. Conductor made of copper-based alloy can withstand high tension. HTW wire not only has all the properties of copper, but also is highly flexible.

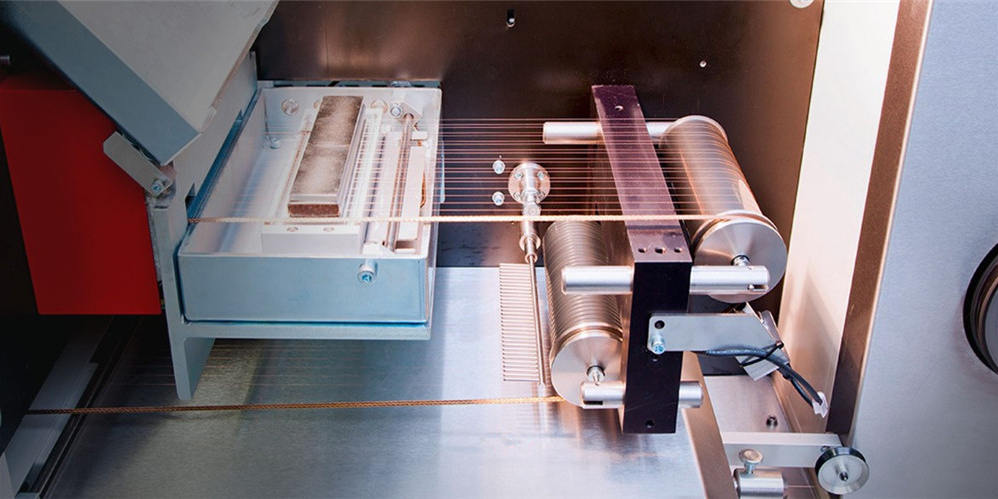

Winding with self-adhesive enameled wire with composite coating renews the mode of conventional transformer manufacturing. It only needs to be activated by hot air into a whole, which has certain mechanical properties and is moisture-proof. Therefore, the self-adhesive magnet wire can be wound into bobbinless coil and prevents dipping. It also shortens lead time to manufacture magnetic components such as electro-acoustic equipment and greatly improve the efficiency of mass production. There are strict requirements for consistency of our magnet wire in mechanical height, resistance, inductance, distributed capacitance and other parameters. So outer diameter tolerance of our high-tension electromagnetic wire must not only meet specified standard but also needs to be absolutely curtailed. This calls for higher requirements in manufacturing technology and equipment.

Properties of High Tension and Ultra High Tension Enameled Wires

High Tension enameled wire (high-tension wire: HTW) is an extremely thin enameled wire that uses copper-based alloy as its conductors. It not only has all the properties of copper, but also has high strength. The specific data are as follows:

Tensile strength is about 25% greater than copper wire. (increase of speed of winding and prevention from wire breakage at the end of coil)

Conductivity is more than 93% of copper.

The same properties of insulation and hot air bonding as of copper wire.

| Specification | |||

| Type | Insulation | Bonding layer | Size range(mm) |

|

HTW |

LSUE UE |

MZWLOCK

LOCK Y1 |

0.015-0.08 |

Soldering ability is the same as copper wire.

|

Comparison of high tension and ultra-high tension enameled wire with ordinary conductor enameled wire |

|||||

|

Conductor type |

Conductivity 20℃(%) |

Tensile strength (N/mm2) |

Proportion(N/mm2) |

Application |

|

|

Copper |

100 |

255 |

8.89 |

Various electronic products |

|

|

CCAW |

67 |

137 |

3.63 |

Voice coils, HHD coils |

|

|

HTW |

HIW |

99 |

335 |

8.89 |

Head coils, Watch coils, Cellphone coils |

|

|

SHIT |

92 |

370 |

8.89 |

|

|

OCC |

|

102 |

245 |

8.89 |

High-quality voice coil etc. |

Transformer

Motor

Ignition coil

Voice Coil

Electrics

Relay

Drawing

Paint

Annealing

Baking

Cooling

Customer Oriented,Innovation brings more Value

RUIYUAN is a solution provider, which requires us to be more professional on wires, insulation material and your applications.

Ruiyuan has a heritage of innovation, along with advancements in enameled copper wire, our company has grown through an unwavering commitment to integrity, service and responsiveness to our customers.

We look forward to continuing to grow on the basis of quality, innovation and service.

7-10 days Average delivery time.

90% European and North American customers. Such as PTR,ELSIT, STS etc.

95% Repurchase rate

99.3% Satisfaction rate. Class A supplier verified by German customer.

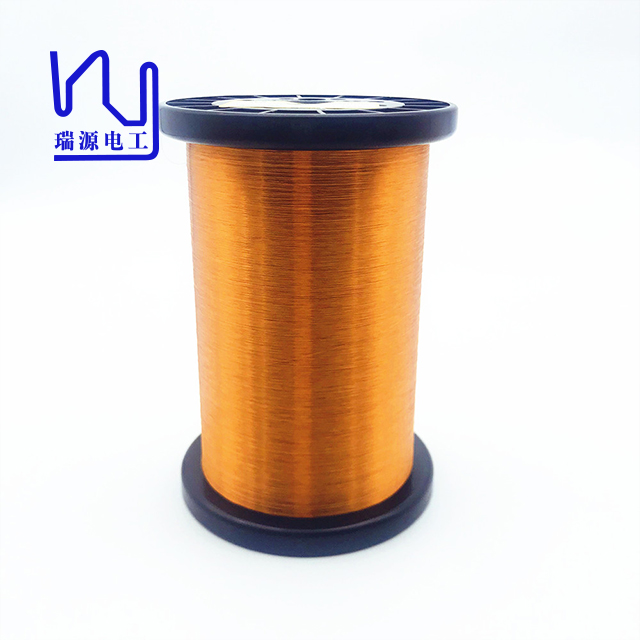

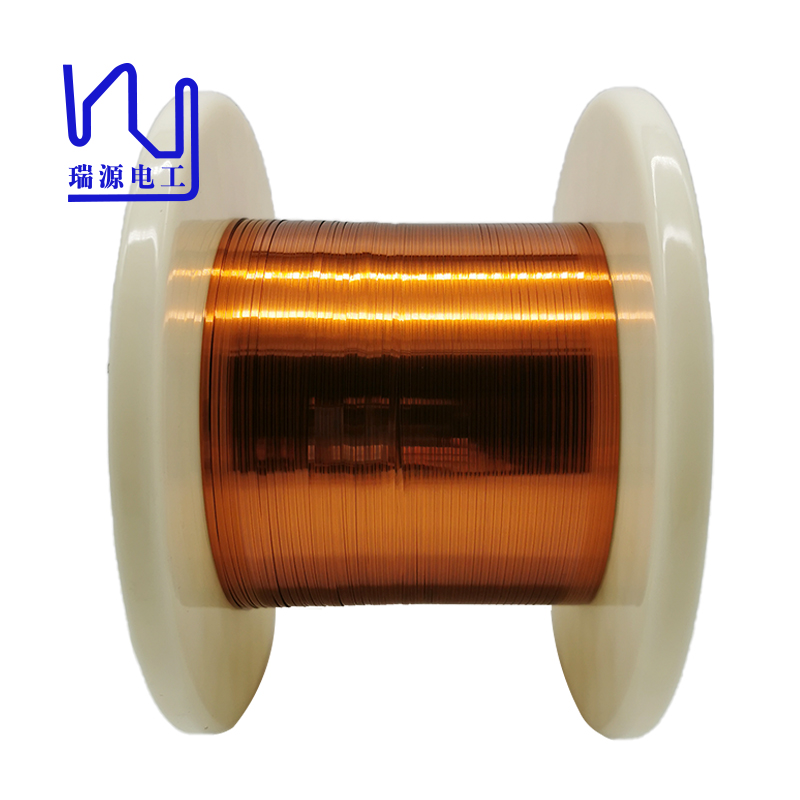

Product detail pictures:

Related Product Guide:

All we do is usually connected with our tenet Customer to start with, Rely on initial, devoting on the food packaging and environmental protection for OEM/ODM Supplier Square Magnet Wire - HTW High Tension Enameled Copper Wire – Ruiyuan , The product will supply to all over the world, such as: UK, Pakistan, USA, We firmly think that we have the full capability to give you contented merchandise. Wish to collect concerns within you and build a new long-term synergy romantic relationship. We all significantly promise:Csame excellent, better selling price; exact selling price, better quality.

This manufacturers not only respected our choice and requirements, but also gave us a lot of good suggestions, ultimately, we successfully completed the procurement tasks.