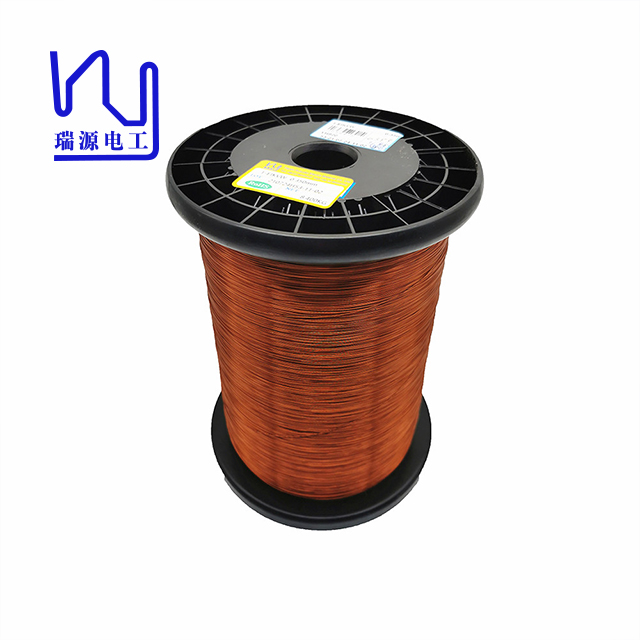

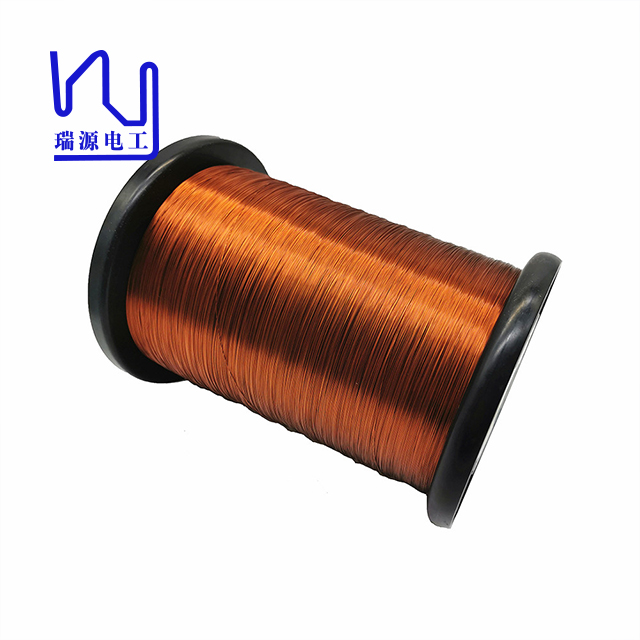

PriceList for 0.02 Mm Copper Winding Wire - EIW 180 Polyedster-imide 0.35mm Enamelled copper wire – Ruiyuan

PriceList for 0.02 Mm Copper Winding Wire - EIW 180 Polyedster-imide 0.35mm Enamelled copper wire – Ruiyuan Detail:

The chemical contents of EIW is Polyedster-imide, which is the combination of Terephthalate and Esterimide. At operating environment of 180C, EIW can maintain good stability and insulating property. Such insulation can be well attached to conductor(adherence).

1,JIS C 3202

2,IEC 60317-8

3,NEMA MW30-C

1. good property in thermal shock

2. Radiation resistance

3. Excellent performance in heat resistance and softening breakdown

4. Excellent thermal stability, scratch resistance, refrigerant resistance and solvent resistance

Applied standard:

JIS C 3202

IEC 317-8

NEMA MW30-C

Our enameled copper wire can be applied to various devices such as heat-resistant motor, four-way valve, induction cooker coil, dry-type transformer, washing machine motor, air conditioner motor, ballast, etc.

Test method and data for adhesion of EIW enameled copper wire are as follows:

For enameled copper wire with diameter less than 1.0mm, jerk test is applied. Take three strands of samples with a length of about 30cm from the same spool and draw marking lines with a distance of 250mm respectively. Pull sample wires at a speed of more than 4m/s till they break. Check with the magnifying glass as specified in the table below to see if there’ s any cleavage or crack of exposed copper or loss of adhesion. Within 2mm won’ t be counted in.

When the diameter of conductor is more than 1.0mm, twisting method (Exfoliation Method) is applied. Take 3 turns of samples with a length of about 100cm from the same spool. The distance between the two chucks of the testing machine is 500mm. Then twist the sample in the same direction at one end of it at a speed of 60-100 rpm per minute. Observe with naked eyes and mark down the number of twists when there’ s exposed copper of enamel. However, when sample is broken during twisting, it’ s a requisite to take another sample from the same spool to continue the test.

| Nominal Diameter |

Enameled Copper Wire (overall diameter) |

Resistance at 20 °C

|

||||||

|

Grade 1 |

Grade 2 |

Grade 3 |

||||||

| [mm] |

min [mm] |

max [mm] |

min [mm] |

max [mm] |

min [mm] |

max [mm] |

min [Ohm/m] |

max [Ohm/m] |

| 0.100 |

0.108 |

0.117 |

0.118 |

0.125 |

0.126 |

0.132 |

2.034 |

2.333 |

| 0.106 |

0.115 |

0.123 |

0.124 |

0.132 |

0.133 |

0.140 |

1.816 |

2.069 |

| 0.110 |

0.119 |

0.128 |

0.129 |

0.137 |

0.138 |

0.145 |

1.690 |

1.917 |

| 0.112 |

0.121 |

0.130 |

0.131 |

0.139 |

0.140 |

0.147 |

1.632 |

1.848 |

| 0.118 |

0.128 |

0.136 |

0.137 |

0.145 |

0.146 |

0.154 |

1.474 |

1.660 |

| 0.120 |

0.130 |

0.138 |

0.139 |

0.148 |

0.149 |

0.157 |

1.426 |

1.604 |

| 0.125 |

0.135 |

0.144 |

0.145 |

0.154 |

0.155 |

0.163 |

1.317 |

1.475 |

| 0.130 |

0.141 |

0.150 |

0.151 |

0.160 |

0.161 |

0.169 |

1.220 |

1.361 |

| 0.132 |

0.143 |

0.152 |

0.153 |

0.162 |

0.163 |

0.171 |

1.184 |

1.319 |

| 0.140 |

0.51 |

0.160 |

0.161 |

0.171 |

0.172 |

0.181 |

1.055 |

1.170 |

| 0.150 |

0.162 |

0.171 |

0.172 |

0.182 |

0.183 |

0.193 |

0.9219 |

1.0159 |

| 0.160 |

0.172 |

0.182 |

0.183 |

0.194 |

0.195 |

0.205 |

0.8122 |

0.8906 |

| Nominal Diameter

[mm] |

Elongation acc to IEC min [%] |

Breakdown Voltage acc to IEC |

Winding Tension max [cN] |

||

|

Grade 1 |

Grade 2 |

Grade 3 |

|||

|

0.100 |

19 |

500 |

950 |

1400 |

75 |

|

0.106 |

20 |

1200 |

2650 |

3800 |

83 |

|

0.110 |

20 |

1300 |

2700 |

3900 |

88 |

|

0.112 |

20 |

1300 |

2700 |

3900 |

91 |

|

0.118 |

20 |

1400 |

2750 |

4000 |

99 |

|

0.120 |

20 |

1500 |

2800 |

4100 |

102 |

|

0.125 |

20 |

1500 |

2800 |

4100 |

110 |

|

0.130 |

21 |

1550 |

2900 |

4150 |

118 |

|

0.132 |

2 1 |

1550 |

2900 |

4150 |

121 |

|

0.140 |

21 |

1600 |

3000 |

4200 |

133 |

|

0.150 |

22 |

1650 |

2100 |

4300 |

150 |

|

0.160 |

22 |

1700 |

3200 |

4400 |

168 |

Transformer

Motor

Ignition coil

Voice Coil

Electrics

Relay

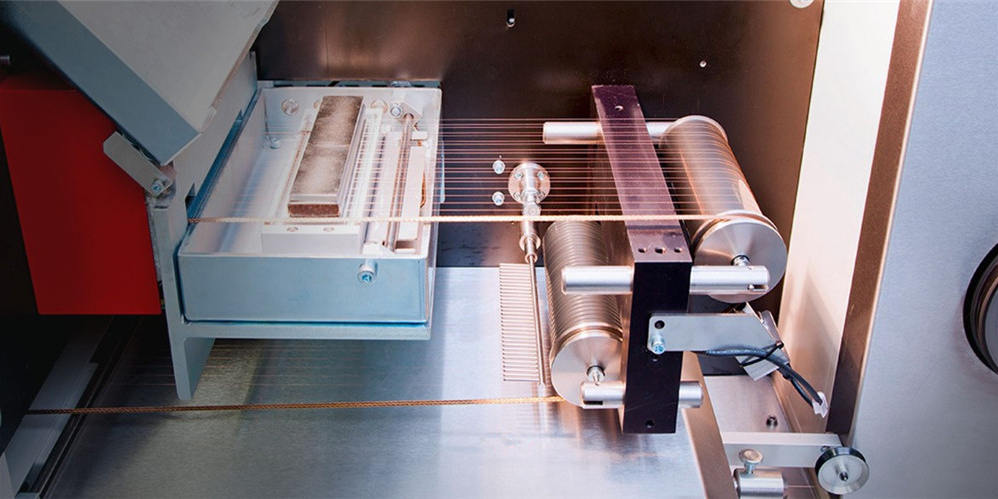

Drawing

Paint

Annealing

Baking

Cooling

Customer Oriented,Innovation brings more Value

RUIYUAN is a solution provider, which requires us to be more professional on wires, insulation material and your applications.

Ruiyuan has a heritage of innovation, along with advancements in enameled copper wire, our company has grown through an unwavering commitment to integrity, service and responsiveness to our customers.

We look forward to continuing to grow on the basis of quality, innovation and service.

7-10 days Average delivery time.

90% European and North American customers. Such as PTR,ELSIT, STS etc.

95% Repurchase rate

99.3% Satisfaction rate. Class A supplier verified by German customer.

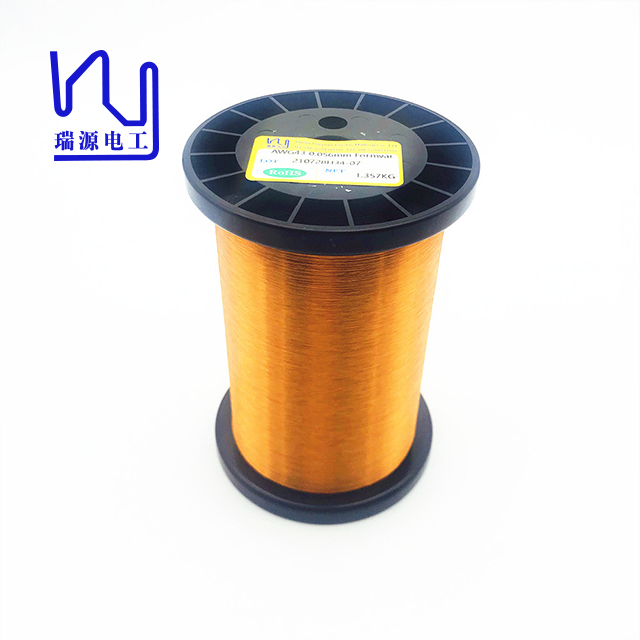

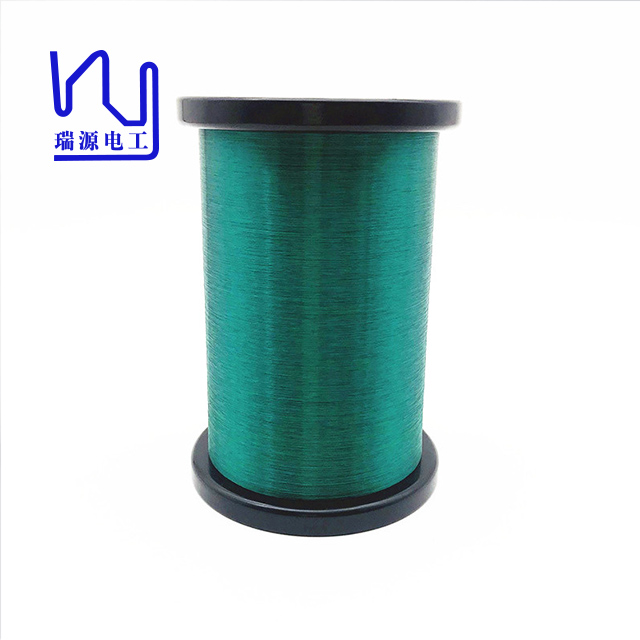

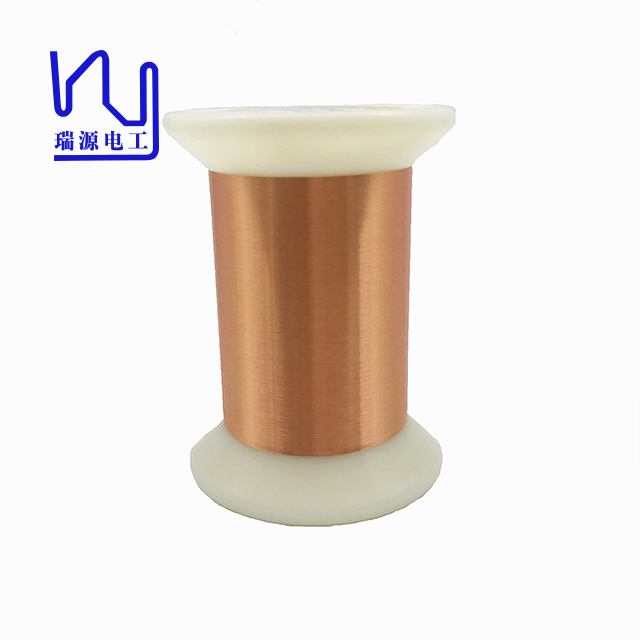

Product detail pictures:

Related Product Guide:

Our organization promises all customers with the first-class products and solutions and the most satisfying post-sale service. We warmly welcome our regular and new clients to join us for PriceList for 0.02 Mm Copper Winding Wire - EIW 180 Polyedster-imide 0.35mm Enamelled copper wire – Ruiyuan , The product will supply to all over the world, such as: South Korea, Italy, Albania, To achieve reciprocal advantages, our company is widely boosting our tactics of globalization in terms of communication with overseas customers, fast delivery, the best quality and long-term cooperation. Our company upholds the spirit of innovation, harmony, team work and sharing, trails, pragmatic progress. Give us a chance and we'll prove our capability. With your kind help, we believe that we can create a bright future with you together.

Cooperate with you every time is very successful, very happy. Hope that we can have more cooperation!