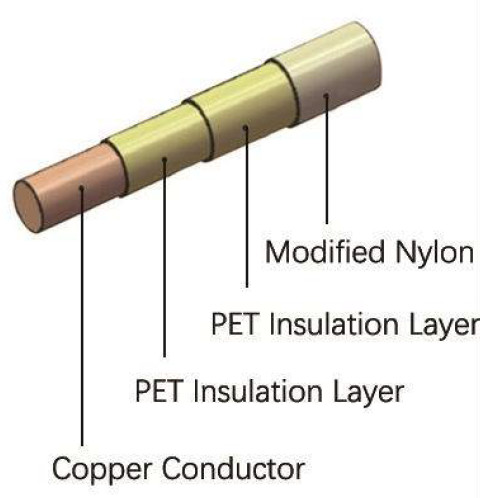

Professional China Teflon Insulated Copper Magnet Wire - Class B / F Triple Insulated Wire 0.40mm TIW Solid Copper Winding Wire – Ruiyuan

Professional China Teflon Insulated Copper Magnet Wire - Class B / F Triple Insulated Wire 0.40mm TIW Solid Copper Winding Wire – Ruiyuan Detail:

TIW-B/F/H, thermal class from 130-180 with such features

Solderability: TIW CLASS B and F can be soldered directly, class H need to peal off

Size range: 0.13-1.0mm

operation voltage 1000Vms

Soldering temperature: 420-470 ℃

Breakdown voltage: Up to 17KV

Solvent resistance: Great performance of chemical solvent and insulating paint resistance

Fast Winding capacity

Complies with UL-2353, VDE, IEC60950/61558 and CQC safety regulation

Conforms EU RoHS 2.0, HF and REACH environment requirement.

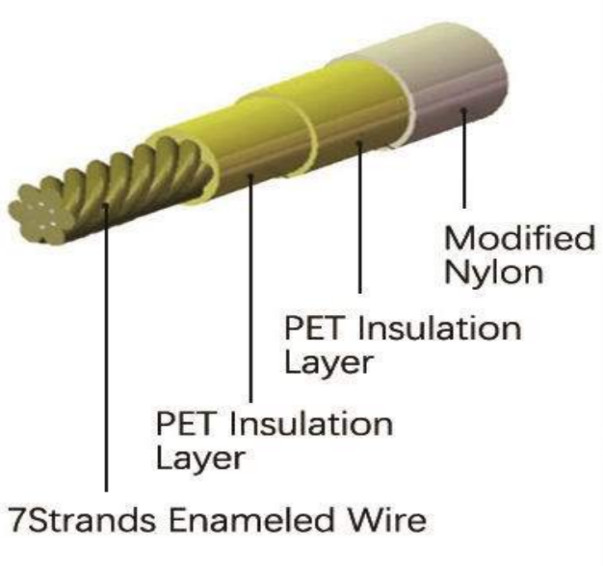

7 Strands triple insulated litz wire

Here are features and benefits of 7stands triple insulated litz wire

Wider thermal class range: From 130-180℃

Size range: 0.10×7-0.30×7

operation voltage 1000Vms

Soldering temperature: 420-470 ℃

Breakdown voltage: Up to 17KV

Solvent resistance: Great performance of chemical solvent and insulating paint resistance

Complies with UL-2353, VDE, IEC60950/61558 and CQC safety regulation

Conforms EU RoHS 2.0, HF and REACH environment requirement

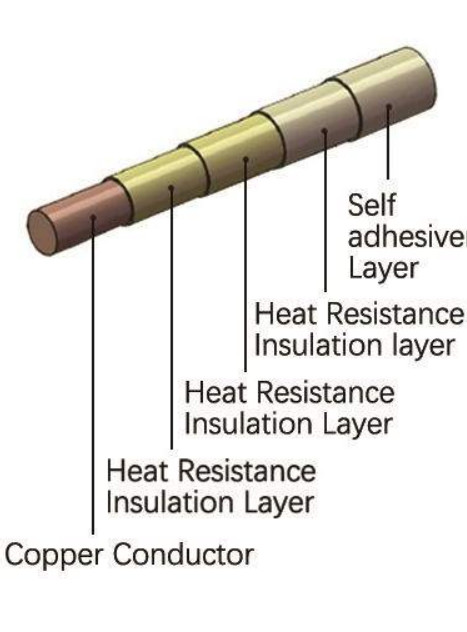

Self bonding triple insulated winding wire

Self bonding or adhesive triple insulated wire was designed for transformer tape replacement that save space of the transformer and reduce the costs

Here are the main features and benefits

Size range: 0.15-1.0mm

Operation voltage 1000Vms

Soldering temperature: 420-470 ℃

Breakdown voltage: Up to 15KV

Complies with UL-2353, VDE, IEC60950/61558 and CQC safety regulation

Conforms EU RoHS 2.0, HF and REACH environment requirement

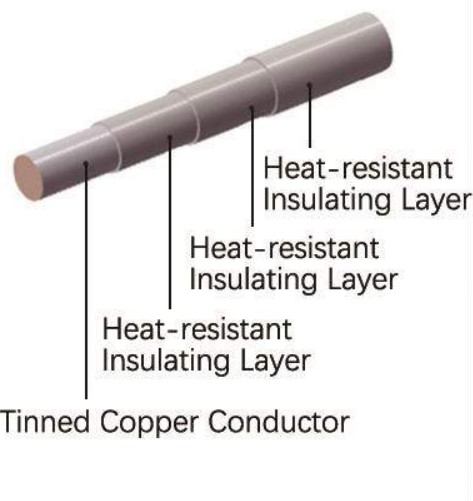

Thermal Class 130-180 ℃ Tinned triple insulated winding wire

Main features and benefits:

Size range: 0.15-1.0mm

Operation voltage 1000Vms

Soldering temperature: 420-470 ℃

Breakdown voltage: Up to 17KV

Complies with UL-2353, VDE, IEC60950/61558 and CQC safety regulation

Conforms EU RoHS 2.0, HF and REACH environment requirement

And also we helped many customer to develop some special wires, we really want to help you to realize your design. Welcome to tell us your creative idea.

1.Production standard range:0.1-1.0mm

2.Withstand voltage class, class B 130℃, class F 155℃.

3.Excellent withstand voltage characteristics, breakdown voltage greater than 15KV, obtained reinforced insulation.

4.No need to peel off the outer layer can be direct welding, solder ability 420℃-450℃≤3s.

5.Special abrasive resistance and surface smoothness, staticfriction coefficient ≤0.155, the product can meet the automatic winding machine high-speed winding.

6.Resistant chemical solvents and impregnated paint performance, Rating voltage Rated voltage(working voltage)1000VRMS, UL.

7.High strength insulation layer toughness, repeated bending strethc, the insulation layers will not crack damage.

Founded in 2002, Ruiyuan has been in the manufacture of enamelled copper wire for 20 years.We combine the best manufacturing techniques and enamel materials to create a high-quality, best-in-class enameled wire. The enameled copper wire lies at the heart of technology we use every day – appliances, generators, transformers, turbines, coils and much more. Nowadays, Ruiyuan has the global footprint to support our partners in marketplace.

Product detail pictures:

Related Product Guide:

We often stay with the principle Quality Very first, Prestige Supreme. We have been fully committed to supplying our consumers with competitively priced high-quality goods, prompt delivery and skilled provider for Professional China Teflon Insulated Copper Magnet Wire - Class B / F Triple Insulated Wire 0.40mm TIW Solid Copper Winding Wire – Ruiyuan , The product will supply to all over the world, such as: Panama, Ghana, Wellington, Strong infrastructure is the need of any organization. We are backed with a robust infrastructural facility that enables us to manufacture, store, quality check and dispatch our products worldwide. To maintain smooth work flow, we have sectioned our infrastructure into a number of departments. All these departments are functional with latest tools, modernized machines and equipment. Owing to which, we are able to accomplish voluminous production without compromising upon the quality.

The company leader recept us warmly, through a meticulous and thorough discussion, we signed a purchase order. Hope to cooperate smoothly