2UEW155 0.4mm Enameled Copper Winding Wire For Transformer/Motor

0.4mm enameled copper wire is an important choice for high-frequency transformer and motor winding applications, demonstrating excellent electrical performance, thermal stability and ease of use. Its contribution to the efficient and reliable operation of electrical equipment is undeniable, and its role in advancing modern technology is also indispensable. As the demand for high-performance electrical components continues to grow, this enameled copper wire remains the cornerstone of innovation and progress in electrical engineering.

·IEC 60317-23

·NEMA MW 77-C

·customized according to customer requirements.

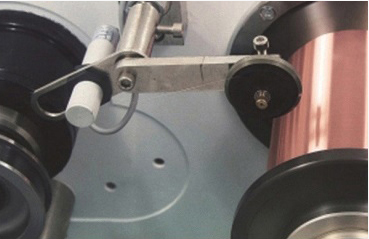

In the field of high frequency transformers, 0.4mm enameled copper wire exhibits excellent characteristics, making it an ideal choice for winding applications. Its uniform diameter and high electrical conductivity ensure efficient energy transfer and reduce energy losses, especially in high-frequency operation. The use of this wire facilitates the production of high-performance transformers essential in power supply units, audio amplifiers, and various electronic equipment. Likewise, in electric motors, 0.4 mm enameled copper wire has clear advantages. Its consistent diameter and excellent thermal stability allow for even winding, which enhances electromagnetic performance and reduces heat generation. This wire helps produce efficient and durable motor windings that allow the motor to operate at optimal levels while maintaining reliability and longevity.

The application of 0.4mm enameled copper wire in high-frequency transformers and motor windings highlights its importance in modern electrical engineering. Its ability to withstand high frequencies and temperatures, coupled with its excellent electrical properties, makes it an indispensable component in transformer and electric motor manufacturing.

|

Test Item |

Unit |

Standard Value |

Reality Value |

|||

|

1st Sample |

2nd Sample |

3rd Sample |

||||

| Appearance |

Smooth & Clean |

OK |

OK |

OK |

OK |

|

| Conductor Diameter |

0.400± |

0.004 |

0.400 |

0.400 |

0.400 |

OK |

| 0.004 | ||||||

| Thickness of Insulation |

≥ 0.025 mm |

0.032 |

0.033 |

0.032 |

OK |

|

| Overall Diameter |

≤ 0.437 mm |

0.432 |

0.433 |

0.432 |

OK |

|

| DC Resistance |

≤ 0.1400 Ω/m |

0.1345 |

0.1354 |

0.1343 |

OK |

|

| Elongation |

≥ 27 % |

31 |

32 |

30 |

OK |

|

| Breakdown Voltage |

≥ 2900 V |

4563 |

4132 |

3986 |

OK |

|

|

Pin Hole |

≤ 5 Faults/5m |

0 |

0 |

0 |

OK |

|

|

Continuity |

≤ 25 Faults/30m |

0 |

0 |

0 |

OK |

|

|

Test Items |

Technical Requests |

Results |

||||

|

Adhesive |

Coating layer is good |

OK |

||||

|

Cut-through |

200℃ 2mins no breakdown |

OK |

||||

|

Heat Shock |

175±5℃/30min no crack |

OK |

||||

|

Solder Ability |

390± 5℃ 2Sec Smooth |

OK |

||||

Automotive coil

sensor

special transformer

special micro motor

inductor

Relay

Customer Oriented,Innovation brings more Value

RUIYUAN is a solution provider, which requires us to be more professional on wires, insulation material and your applications.

Ruiyuan has a heritage of innovation, along with advancements in enameled copper wire, our company has grown through an unwavering commitment to integrity, service and responsiveness to our customers.

We look forward to continuing to grow on the basis of quality, innovation and service.

7-10 days Average delivery time.

90% European and North American customers. Such as PTR,ELSIT, STS etc.

95% Repurchase rate

99.3% Satisfaction rate. Class A supplier verified by German customer.