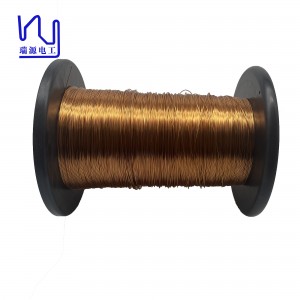

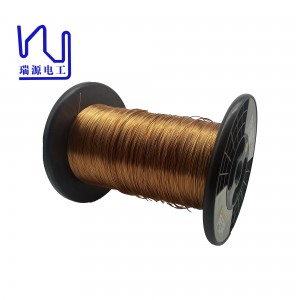

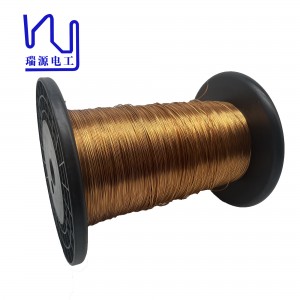

2UEWF/H 0.95mm Enameled Copper Wire For High Frequency Transformer

There are several advantages to using enameled copper wire in transformer windings.

1. The thin insulating coating provides excellent dielectric properties, ensuring efficient energy transfer.

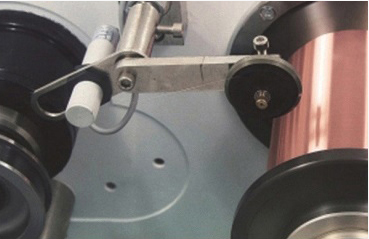

2. Copper's flexibility and durability make it an ideal material for manufacturing tightly wound coils, resulting in high-performance transformers capable of handling varying electrical loads. When it comes to transformer manufacturing, the quality and reliability of enamelled copper wire are crucial. Our enamelled copper wire is manufactured to the highest industry standards, ensuring uniform insulation thickness and excellent adhesion, which is vital to maintaining the integrity of the windings during the life of the transformer.

3.Our dedicated technical support team can help customers select the most appropriate enameled copper wire for their specific transformer design. With our expertise and commitment to quality, we aim to provide the best solutions for transformer winding applications, helping our customers achieve superior electrical performance and reliability.

·IEC 60317-23

·NEMA MW 77-C

·customized according to customer requirements.

Enameled copper wire plays a vital role in the construction of transformers and our custom wire products provide the durability, temperature resistance and performance required for demanding applications. Whether a standard design or a custom application, our enameled copper wire is ideal for achieving high-quality transformer windings with excellent electrical performance and long-term reliability.

| Conductor | Min.film thickness | overall dimensionmm | Breakdownvoltage V | Resistance

Ω/km(20℃) |

||

| Dia. mm | Tolerance mm | mm | Min | Max | ||

| 0.95 | ±0.020 | 0.034 | 1.018 | 1.072 | 5100 | 25.38 |

Automotive coil

sensor

special transformer

special micro motor

inductor

Relay

Customer Oriented,Innovation brings more Value

RUIYUAN is a solution provider, which requires us to be more professional on wires, insulation material and your applications.

Ruiyuan has a heritage of innovation, along with advancements in enameled copper wire, our company has grown through an unwavering commitment to integrity, service and responsiveness to our customers.

We look forward to continuing to grow on the basis of quality, innovation and service.

7-10 days Average delivery time.

90% European and North American customers. Such as PTR,ELSIT, STS etc.

95% Repurchase rate

99.3% Satisfaction rate. Class A supplier verified by German customer.