Class 220 0.35mmx37 Self adhesive Copper Litz Wire For Winding

|

Characteristics

|

Technical requests

|

Test Results |

||

| Sample 1 |

Sample |

Sample 3 |

||

|

Surface |

Good |

OK |

OK |

OK |

|

Single wire inner diameter |

0.347-0.353mm |

0.350 |

0.350 |

0.349 |

|

Single wire Outer diameter |

0.376-0.382mm |

0.380 |

0.380 |

0.380 |

|

Outer diameter of litz Wire |

<2.290mm |

2.290 | ||

|

Outer diameter of bonding litz Wire |

<2.490mm |

2.216 | ||

|

Twist Pitch |

45±5 |

45 |

||

|

Breakdown Voltage |

>1100V |

2900V |

2800V |

|

|

Pinhole Test |

<27holes/5m |

0 |

0 |

0 |

|

Conductor Resistance |

<0.00669-0.00692Ω/m ( 20℃) |

0.006901 | ||

|

Soldering test |

390 ±5 ℃ 7-10S |

OK |

OK |

OK |

Electric Vehicles and Transportation: In drive motor windings, self-adhesive Litz wire helps reduce high-frequency harmonic losses, making it suitable for advanced motor designs. It is also used in DC-DC converters, where inductors and transformers efficiently convert high-voltage electricity to low-voltage electricity.

Medical Equipment: In magnetic resonance imaging (MRI) machines, lead wires are key components of gradient coils and radio frequency coils because low-frequency loss and precise shape are crucial. They are also used in high-frequency surgical equipment and X-ray generators to ensure reliable performance.

Audio Equipment: High-end audio systems benefit from Litz lines in crossover inductors, which improve sound quality by reducing high-frequency losses.

The self-adhesive layer provides structural fixation without the need for additional adhesive materials, thus simplifying the winding process and improving consistency. Furthermore, the tighter contact between conductors enhances heat dissipation and provides better environmental resistance.

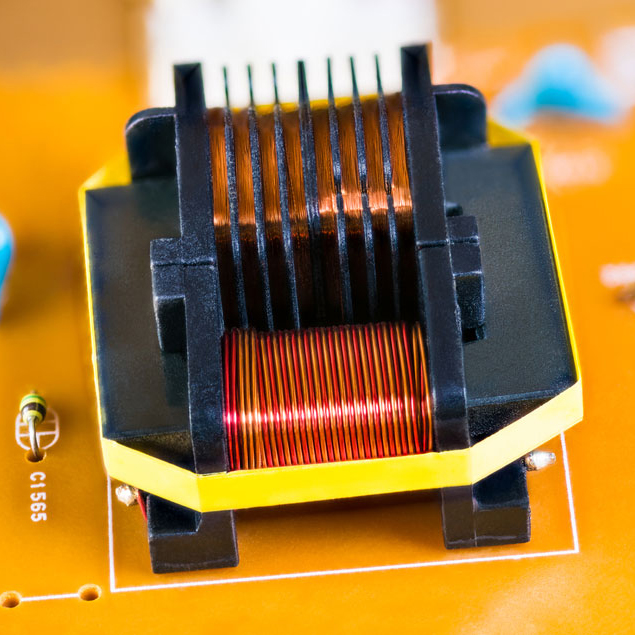

Self-adhesive Litz wire is a specialized electromagnetic wire designed for high-performance applications. This wire uses a single 0.35 mm diameter strand composed of 37 individually insulated strands. It has a temperature rating up to 220 degrees Celsius, The unique feature of this wire is its self-adhesive property; as shown in the image, each strand is tightly bonded together, enhancing its structural integrity

Founded in 2002, Ruiyuan has been in the manufacture of enamelled copper wire for 20 years.We combine the best manufacturing techniques and enamel materials to create a high-quality, best-in-class enameled wire. The enameled copper wire lies at the heart of technology we use every day – appliances, generators, transformers, turbines, coils and much more. Nowadays, Ruiyuan has the global footprint to support our partners in marketplace.

Our Team

Ruiyuan attracts many outstanding technical and management talents, and our founders have built the best team in the industry with our long-term vision. We respects the values of each employee and provides them with a platform to make Ruiyuan a great place to grow a career.