Motors account for 5-10% of the vehicle value. VOLT adopted flat-wire motors as early as 2007, but didn’ t use on a large scale, mainly because there were many difficulties in raw materials, processes, equipment, etc. In 2021, Tesla replaced the with china made flat wire motor. BYD started the development of flat wire motors as early as 2013, and developed its own production process for flat copper wires, which solved a series of problems such as springback, insulation deformation, corona resistance, end twisting, stator insertion accuracy. Now efficiency of BYD’s flat wire motor has reached a world-leading 97.5%.

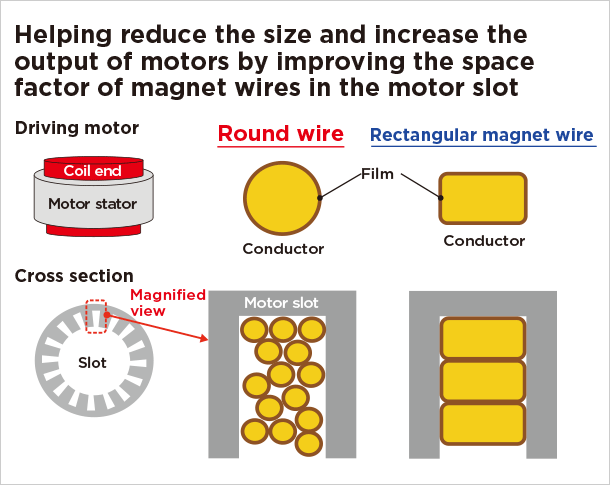

Among the top 15 electric vehicles sales in the first half of this year, the penetration rate of flat wire motors has increased significantly to 27%. The industry predicts that flat wires will account for more than 80% of new energy vehicle drive motors in 2025. Tesla’ s using flat wire motors had led to a significant increase in the penetration rate, and the trend of flat wire motor has been determined. Why’ s that businesses turn to use flat wire? Check the following example and you’ ll understand the benefits.

Tianjin Ruiyuan flat wire products are approved by leading enterprises of EV, and we have more than 60 important flat wire projects. As the first professional manufacturer of precision small flat enameled wire in China, specializing in research and development, production and sales of flat wire, and we are able to systematically provide holographic services from drawing, calendering, painting, mold making, sample, testing and simulation. Our flat wire products are widely used in 5G communications, 3C consumer electronics, vehicle electronics, photovoltaic products and many other fields.

From the previous orders, it’ s highly predictable that production of flat wire has become an accelerating trend, driven by customer demand. Supply of flat wire has entered a high-speed expansion period.

Post time: Jul-11-2023