Continuously transposed cable or Continuously transposed conductor consist some bundles of round and rectangular enameled copper wire made into a assembly and usually covered other insulation like paper, polyester film etc.

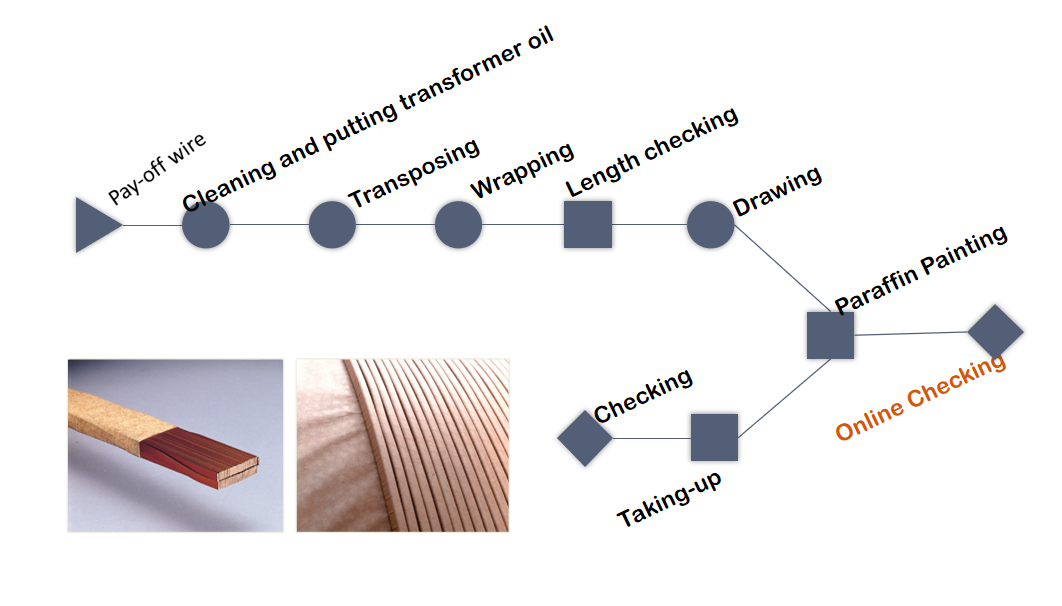

How CTC are made?

Advantage of CTC

Compared to the conventional paper insulated conductors, they offer the following advantages:

1.Shortened winding time for the coil transformer.

2.Decreased size and weight of the transformer, and reduce the cost.

3.Reduced eddy and circulating current losses.

4.Excellent coil performance and simplified winding processing

5.Improved mechanical strength of winding. (Hardened self-bonding CTC)

Insulation of CTC

Kraft papers

22HCC Dennison paper

High density paper

Thermally up-graded papers

Crepe papers

Nomex papers

Polyester film (PET) Papers with epoxy resin

Glass woven Polyester Mesh

Others

Quality Control

Continuously transposed conductors are used in electrical machines at a very high cost per unit. For this reason the quality is strictly controlled during the entire production,e.g.

Bare wire drawing Continuous monitoring of dimensions surface condition geometry

Enameling Dielectrics surface conduction

Transposing Accuracy of transpositions

insulation between strands

Production Range

Round CTC

Max.Strand Min.Size

39 3.00*1.00

49 4.00*1.20

63 5.00*1.20

Rectangular CTC

Item Single Rectangular CTC Rectangular

Post time: Dec-11-2023