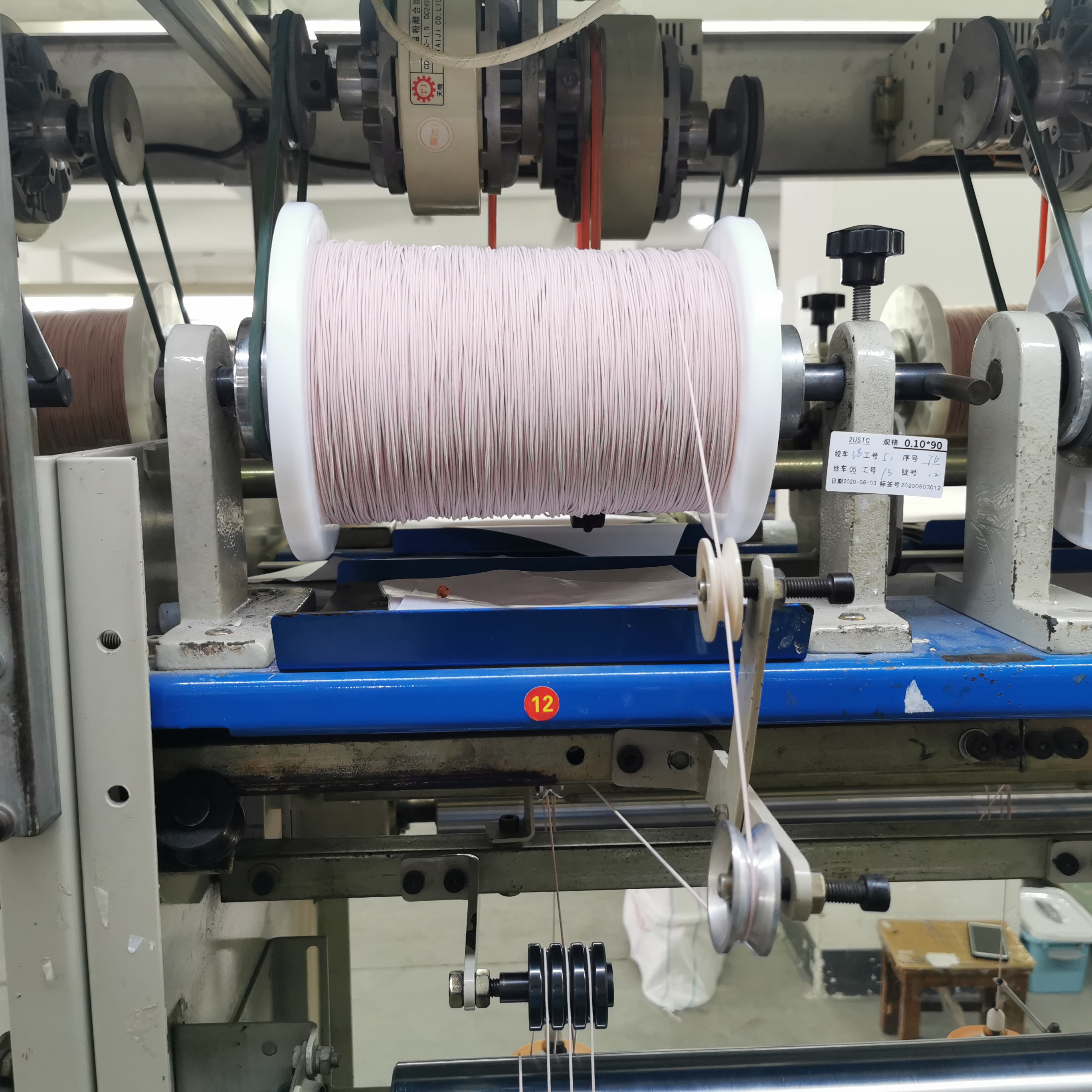

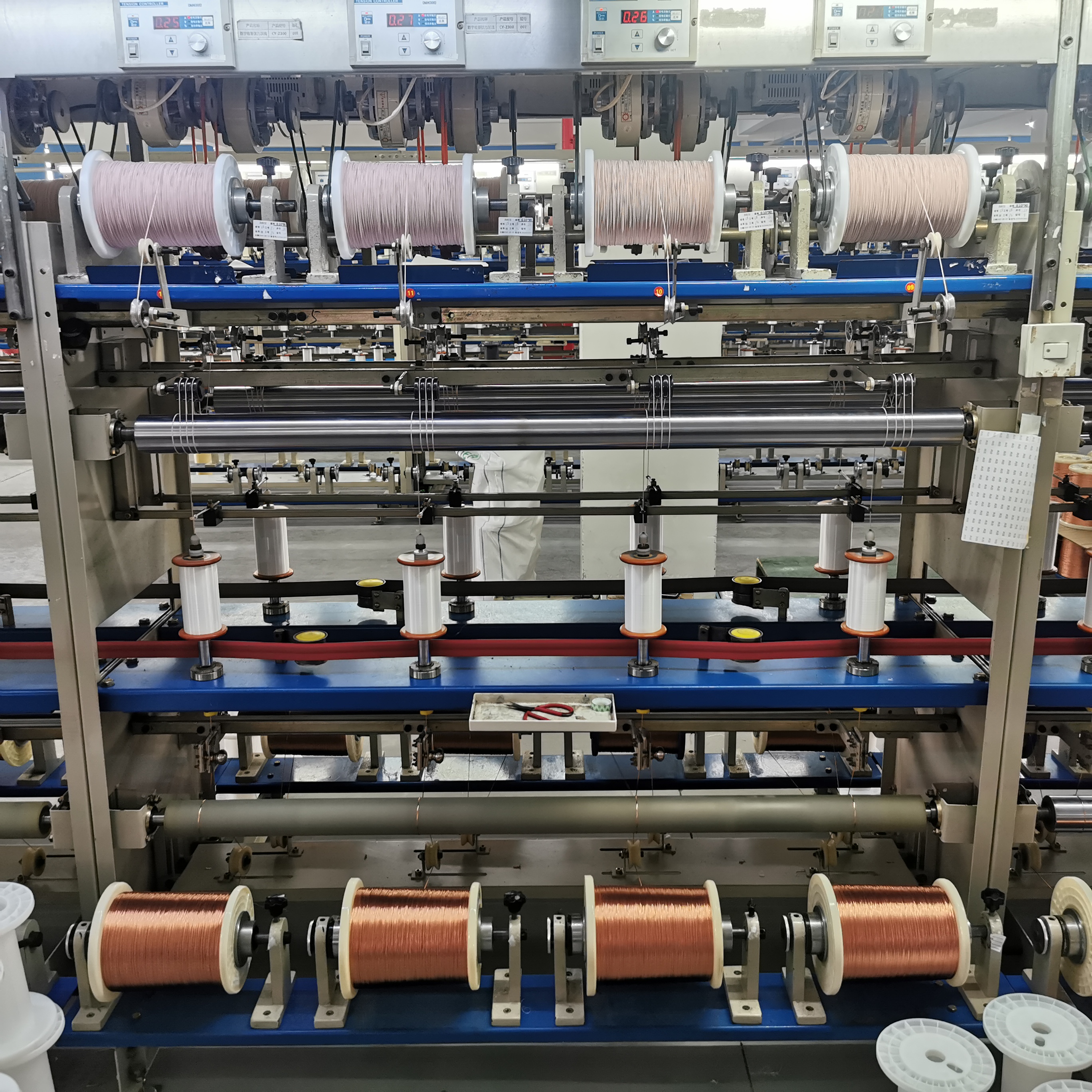

0.08×700 USTC155 / 180 High Frequency Ssilk Covered Litz Wire

Hot air or hot wind and solvent, however we recommend to choose hot air bonding layer,. because the hot air bonding process is environmentally friendly compared to solvent bonding process, allows faster winding, and has potential for process automation. Very thin coils can be produced with self bonding silk severed litz wire unique construction giving additional space for designers or to help to achieve miniaturization goals.

1.High winding speed. Wind the wire and blow the hot air by heat gun, don’t need to choose glue the adhesive the coils separately, that greatly enhance the winding speed and quanlity

2.Solderable without pre-stripping of insulation. Recommended soldering temperature

380-420℃for several seconds,

3.Thin walled overcoat allows small coils.

4.Excellent bonding strengths with hot air bonding.

| Test report: 2USATC 0.08mm x 700 strands, thermal grade 155℃ | |||

|

No. |

Characteristics |

Technical requests |

Test Results |

|

1 |

Surface |

Good |

OK |

|

2 |

Single wire outer diameter (mm) |

0.086-0.103 |

0.087 |

|

3 |

Single wire inner diameter(mm) |

0.08±0.003 |

0.079 |

|

5 |

Overall diameter(mm) |

Max. 3.70 |

2.92 |

|

6 |

Pinhole Test |

Max. 3pcs/6m |

1 |

|

7 |

Breakdown Voltage |

Min. 1100V |

2800V |

|

8 |

Length of Lay |

40±3mm |

40 |

|

9 |

Conductor Resistance Ω/km(20℃) |

Max.5.393 |

5.22 |

| Serving Material | Nylon | Dacron |

| Diameter of single wires1 | 0.03-0.4mm | 0.03-0.4mm |

| Number of single wires2 | 2-5000 | 2-5000 |

| outer diameter of litz wires | 0.08-3.0mm | 0.08-3.0mm |

| Number of layers (typ.) | 1-2 | 1-2 |

The data of Thermo adhesive yarns is also applicable

1.Diameter of the copper

2.Depends on numbers of single wire

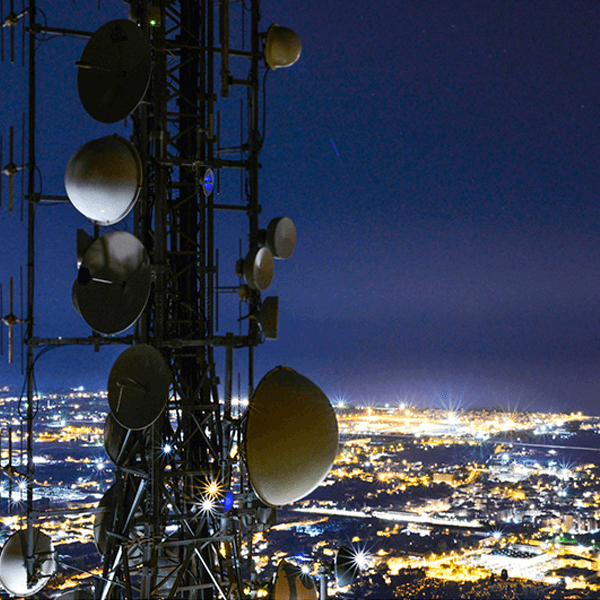

Wireless charger

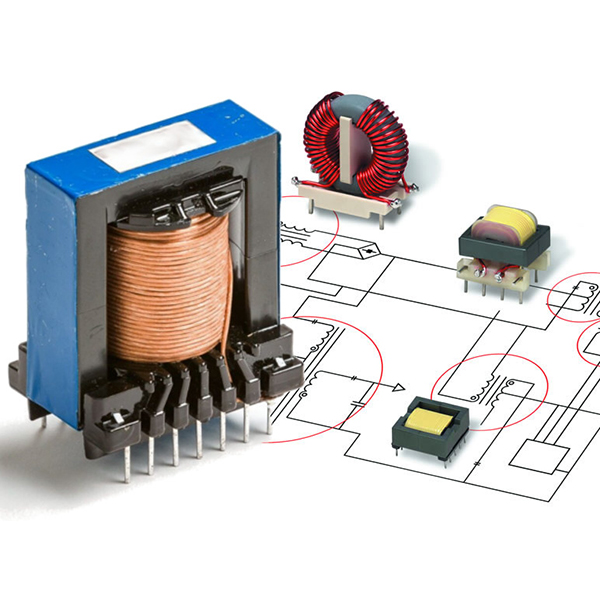

High frequency transformer

High freqeuncy converters

High frequency transceivers

HF chokes

Founded in 2002, Ruiyuan has been in the manufacture of enamelled copper wire for 20 years.We combine the best manufacturing techniques and enamel materials to create a high-quality, best-in-class enameled wire. The enameled copper wire lies at the heart of technology we use every day – appliances, generators, transformers, turbines, coils and much more. Nowadays, Ruiyuan has the global footprint to support our partners in marketplace.

Our Team

Ruiyuan attracts many outstanding technical and management talents, and our founders have built the best team in the industry with our long-term vision. We respects the values of each employee and provides them with a platform to make Ruiyuan a great place to grow a career.