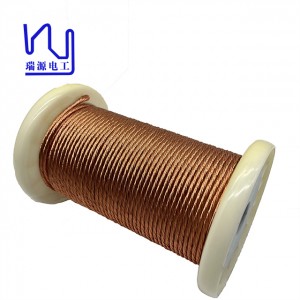

0.10mm*600 Solderable High Frequency Copper Litz Wire

| Test report: 0.1mm x 600 strands,temperature class 155℃ | |||

| No. | Characteristics | Technical requests | Test Results |

| 1 | Surface | Good | OK |

| 2 | Single wire outer diameter

(mm) |

0.100 | 0.220-0.223 |

| 3 | Single wire inner diameter(mm) | 0.200±0.003 | 0.198-0.20 |

| 4 | Overall diameter(mm) | Max. 2.50 | 2.10 |

| 5 | Pinhole Test | Max. 40pcs/6m | 4 |

| 6 | Breakdown Voltage | Min. 1600V | 3600V |

| 7 | Conductor Resistance

Ω/m(20℃) |

Max. 0.008745 | 0.00817 |

Power wireless inductive

Medical equipment

Communications equipment

Ultrasonic photovoltaic inverter

High frequency inductors and transformers

Compared to single enameled wire,litz wire’s surface area will be 200%-3400% more with same cross section,and the wire is more flexible.With this advantage,litz wire is the first choice in high frequency or smaller frame size.

We can customize litz wire, according to the single wire diameter and strands number required by the customer. The specs are as follow:

·Single Wire Diameter: 0.040-0.500mm

·Strands: 2-8000pcs

·Overall Diamter: 0.095-12.0mm

New design or recommendation according to customer requirements for size,turns,current,

power and environmental parameters.

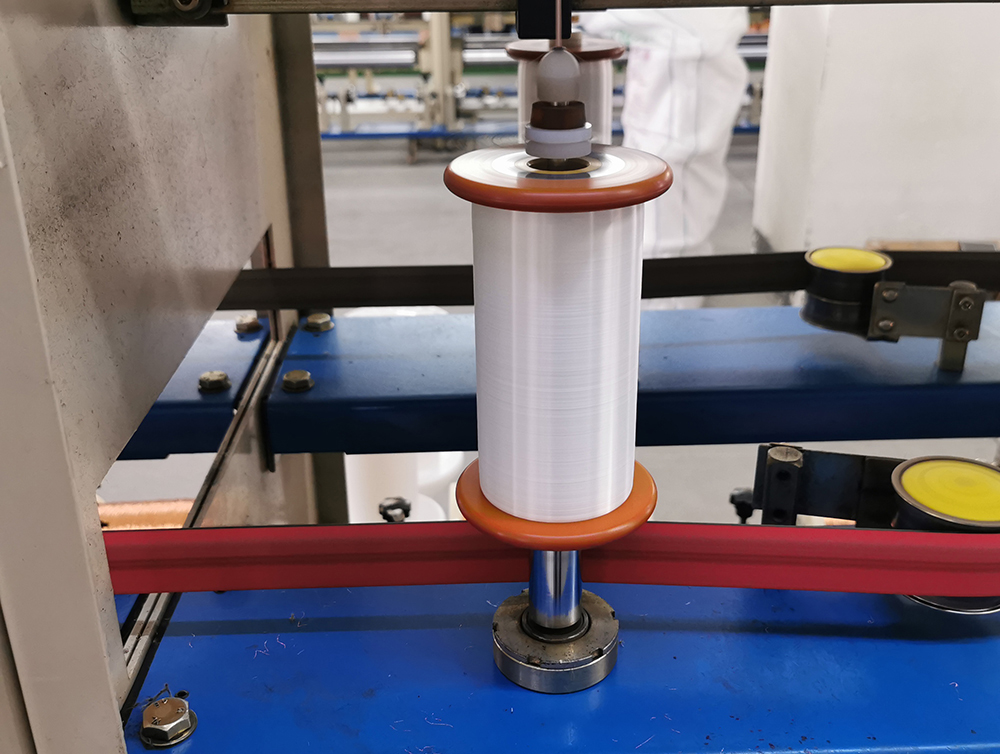

Customers to use automatic line machine,semi-automatic machine,cutting coiling,please tell us,so that we can provide the best solutions

5G base station power supply

EV Charging Stations

Industrial Motor

Maglev Trains

Medical Electronics

Wind Turbines

Founded in 2002, Ruiyuan has been in the manufacture of enamelled copper wire for 20 years.We combine the best manufacturing techniques and enamel materials to create a high-quality, best-in-class enameled wire. The enameled copper wire lies at the heart of technology we use every day – appliances, generators, transformers, turbines, coils and much more. Nowadays, Ruiyuan has the global footprint to support our partners in marketplace.

Our Team

Ruiyuan attracts many outstanding technical and management talents, and our founders have built the best team in the industry with our long-term vision. We respects the values of each employee and provides them with a platform to make Ruiyuan a great place to grow a career.