3SEIW 0.025mm/28 OFC Litz Wire Oxygen-Free Copper Stranded Winding Wire

| Test report: 0.025mm x 28 strands, thermal grade 155℃/180℃ | |||

|

No. |

Characteristics |

Technical requests |

Test Results |

|

1 |

Surface |

Good |

OK |

|

2 |

Single wire outer diameter (mm) |

0.026-0.029 |

0.027 |

|

3 |

Single wire inner diameter(mm) |

0.025±0.003 |

0.024 |

|

4 |

Overall diameter(mm) |

Max. 0.183 |

0.17 |

|

5 |

Pitch(mm) |

6.61 |

√ |

|

6 |

Breakdown Voltage |

Min. 200V |

1000V |

|

7 |

Conductor Resistance Ω/m(20℃) |

Max. 1.685 |

1.300 |

| TEST RESULT(S) of OFC | ||||||||||||||||||

| ITEM(S) | UNIT | RESULT | METHOD | INST | /PLACE MDL | |||||||||||||

| CADMIUM(Cd) | ㎎/㎏ | N.D. | IEC62321-5: 2013 | ICP-OES* | 2 | |||||||||||||

| LEAD(Pb) | ㎎/㎏ | N.D. | IEC62321-5: 2013 | ICP-OES* | 2 | |||||||||||||

| MERCURY(Hg) | ㎎/㎏ | N.D. | IEC62321-4: 2013+AMD1: 2017 | ICP-OES* | 2 | |||||||||||||

| CHROMIUM(Cr) | ㎎/㎏ | N.D. | IEC62321-5: 2013/EPA3052 | ICP-OES* | 2 | |||||||||||||

| CHROMIUM VI(Cr(VI)) | μg/㎠ | N.D. | IEC62321-7-1: 2015 | UV/VIS | 0.01 | |||||||||||||

| Polybrominated biphenyls(PBBs) | ||||||||||||||||||

| Monobromobiphenyl | ㎎/㎏ | N.D. | IEC62321-6: 2015 | GC/MS | 5 | |||||||||||||

| Dibromobiphenyl | ㎎/㎏ | N.D. | 5 | |||||||||||||||

| Tribromobiphenyl | ㎎/㎏ | N D | 5 | |||||||||||||||

| Tetrabromobiphenyl | ㎎/㎏ | N.D. | 5 | |||||||||||||||

| Pentabromobiphenyl Hexabromobiphenyl |

㎎/㎏ ㎎/㎏ |

N.D. N.D. |

5 5 |

|||||||||||||||

| Heptabromobiphenyl | ㎎/㎏ | N.D. | 5 | |||||||||||||||

| Octabromobiphenyl | ㎎/㎏ | N D | 5 | |||||||||||||||

| Nonabromobiphenyl | ㎎/㎏ | N.D. | 5 | |||||||||||||||

| Decabromobiphenyl | ㎎/㎏ | N.D. | 5 | |||||||||||||||

| Polybrominated diphenyl ethers(PBDEs) | ||||||||||||||||||

| Monobromodiphenyl ether | ㎎/㎏ | N.D. | IEC62321-6: 2015 | GC/MS | 5 | |||||||||||||

| Dibromodiphenyl ether | ㎎/㎏ | N D | 5 | |||||||||||||||

| Tribromodiphenyl ether | ㎎/㎏ | N.D. | 5 | |||||||||||||||

| Tetrabromodiphenyl ether | ㎎/㎏ | N.D. | 5 | |||||||||||||||

| Pentabromodiphenyl ether Hexabromodiphenyl ether |

㎎/㎏ ㎎/㎏ |

N.D. N.D. |

5 5 |

|||||||||||||||

| Heptabromodiphenyl ether | ㎎/㎏ | N D | 5 | |||||||||||||||

| Octabromodiphenyl ether | ㎎/㎏ | N.D. | 5 | |||||||||||||||

| Nonabromodiphenyl ether | ㎎/㎏ | N.D. | 5 | |||||||||||||||

| Decabromodiphenyl ether | ㎎/㎏ | N.D. | 5 | |||||||||||||||

| PHTHALATES DIBUTYL PHTHALATE(DBP) DI(2-ETHYLHEXYL) PHTHALATE(DEHP) BUTYLBENZYL PHTHALATE(BBP) DIISOBUTYL PHTHALATE(DIBP) |

㎎/㎏ ㎎/㎏ ㎎/㎏ ㎎/㎏ |

N.D. N.D. N.D. N.D. |

IEC62321-8: 2017 IEC62321-8: 2017 IEC62321-8: 2017 IEC62321-8: 2017 |

GC/MS GC/MS GC/MS GC/MS |

50 50 50 50 |

|||||||||||||

| NOTES: mg/kg = ppm, N.D. = Not Detected, INST. = INSTRUMENT, MDL = Method Detection Limit | ||||||||||||||||||

The ultra-fine wire diameter of Litz wire is one of its great advantages.

Compared with other traditional wires, Litz wire has a higher fineness and can be more easily adapted to precision needs. Whether in electronic equipment, medical equipment or other high-precision fields, Litz wire can provide reliable and efficient connections.

The Litz wire's ultra-fine strand design provides the perfect balance between softness and strength. This allows the litz wire to bend freely in tight spaces without breaking or being damaged.

For engineers and technicians, this means that they can route and connect circuits more easily and improve work efficiency. Not only that, but the withstand voltage of litz wire is also one of the highlights of its performance.

The minimum withstand voltage of 200 volts makes it very suitable for use in high voltage environments. Whether it is in household appliances, automotive electronic systems or other occasions that need to withstand high pressure, Liz wire can stably transmit power signals.

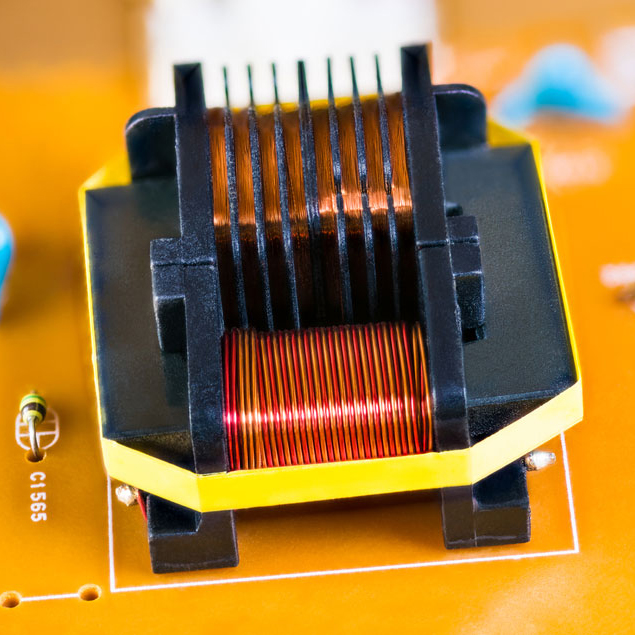

The uses of litz wire are wide and varied. In the field of electronic equipment, Liz wire can be applied to the internal connection of equipment such as mobile phones, tablet computers, cameras and audio equipment.

In the field of medical devices, Litz wire can be used in high-precision medical devices such as cardiac pacemakers, nerve electrical stimulators and implantable devices in the body. In addition,Litz wire is widely used in aerospace, automotive and industrial fields.

5G base station power supply

5G base station power supply

EV Charging Stations

EV Charging Stations

Industrial Motor

Founded in 2002, Ruiyuan has been in the manufacture of enamelled copper wire for 20 years.We combine the best manufacturing techniques and enamel materials to create a high-quality, best-in-class enameled wire. The enameled copper wire lies at the heart of technology we use every day – appliances, generators, transformers, turbines, coils and much more. Nowadays, Ruiyuan has the global footprint to support our partners in marketplace.

Our Team

Ruiyuan attracts many outstanding technical and management talents, and our founders have built the best team in the industry with our long-term vision. We respects the values of each employee and provides them with a platform to make Ruiyuan a great place to grow a career.