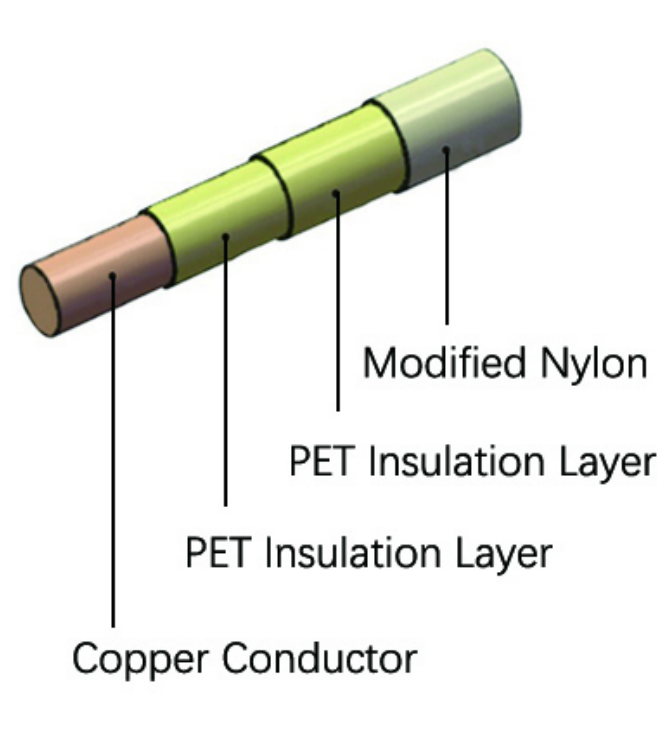

Class 130/155 Yellow TIW Triple insulated winding wire

1.High breakdown voltage. Up to 17KV

2.UL system certificated. Unlike UL certificate, UL system certificate is much more strict, that needs 5000 continuous hours test, if the wire failed below 5000hours, the experiment need to start again. Very a few manufacture can pass such strict test.

3.Very competitive price with top quality. We can compare quality with any other brand.

4.Conforms EU RoHS 2.0, HF AND REACH environment requirements

5.Complies with UL-2353, VDE IEC60950/61558 and CQC safety requirements

6.Stock for all sizes are available.

7.Low MOQ: 1500-3000meters with different single size

8.Wide size range: 0.13-1.00mm class B and class F available

9.Multiple colors options: Besides yellow, red, blue, green, pink are all available but with higher MOQ

10.7 strands of TIW is also available

Here are different types of triple insulated wire we offer

| Description | Designation | Thermal Grade

(℃) |

Diameter

(mm) |

Breakdown

Voltage(KV) |

Solderability

(Y/N) |

| Triple InsulatedCopper Wire | Class B/F/H | 130/155/180 | 0.13mm-1.0mm | ≧17 | Y |

| Tinned | 130/155/180 | 0.13mm-1.0mm | ≧17 | Y | |

| Self Bonding | 130/155/180 | 0.13mm-1.0mm | ≧15 | Y | |

| seven strand litz wire | 130/155/180 | 0.10*7mm-0.37*7mm | ≧15 | Y |

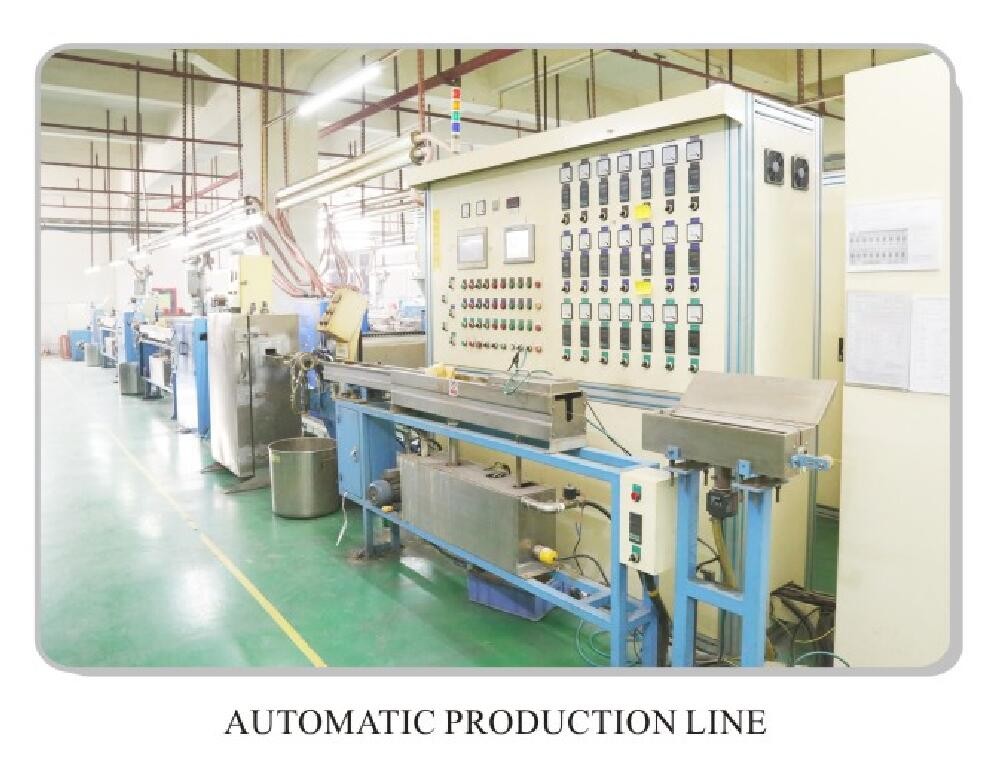

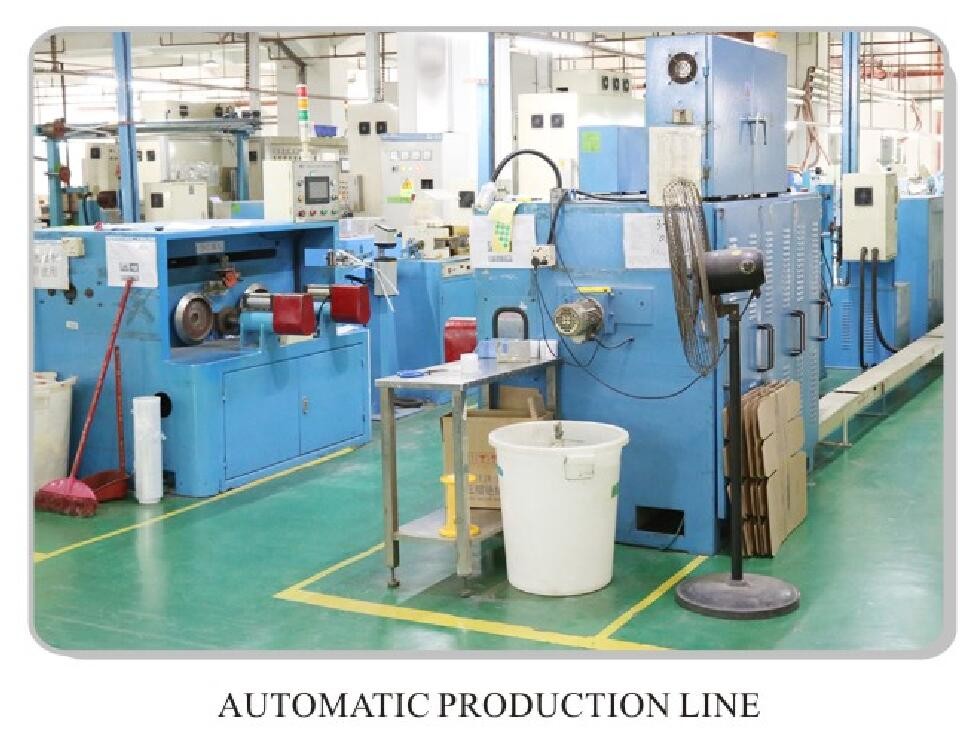

1.Production standard range:0.1-1.0mm

2.Withstand voltage class, class B 130℃, class F 155℃.

3.Excellent withstand voltage characteristics, breakdown voltage greater than 15KV, obtained reinforced insulation.

4.No need to peel off the outer layer can be direct welding, solder ability 420℃-450℃≤3s.

5.Special abrasive resistance and surface smoothness, staticfriction coefficient ≤0.155, the product can meet the automatic winding machine high-speed winding.

6.Resistant chemical solvents and impregnated paint performance, Rating voltage Rated voltage(working voltage)1000VRMS, UL.

7.High strength insulation layer toughness, repeated bending strethc, the insulation layers will not crack damage.

5G Base Station Power Supply

Aerospace

Maglev Trains

Wind Turbines

New Energy Automobile

Electronics

Founded in 2002, Ruiyuan has been in the manufacture of enamelled copper wire for 20 years.We combine the best manufacturing techniques and enamel materials to create a high-quality, best-in-class enameled wire. The enameled copper wire lies at the heart of technology we use every day – appliances, generators, transformers, turbines, coils and much more. Nowadays, Ruiyuan has the global footprint to support our partners in marketplace.

Ruiyuan attracts many outstanding technical and management talents, and our founders have built the best team in the industry with our long-term vision. We respects the values of each employee and provides them with a platform to make Ruiyuan a great place to grow a career.