UL Certified 0.40mm TIW Customized Blue Color Triple Insulated Copper Wire For Transformers

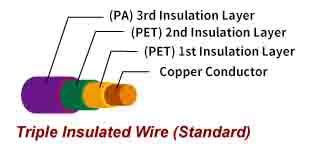

Triple Insulation Wire(Tex-e wire) is a kind of high performance insulation wire, this wire has three insulation layers, the middle is copper core wire, the first layer is golden polyamine film, its thickness is a few microns, but can withstand 2KV pulse high pressure, the second layer is high insulation spray paint coating, The third layer is transparent nylon modified glass fiber layer, the total thickness of the insulation

layer is only 20-100um, its advantages are high insulation strength, any two layers can withstand 2000V AC voltage, high current density. The weight and volume of the transformer can be reduced.

|

Characteristics |

Test Standard |

Conclusion |

|

|

1 |

Package |

Whether Package condition is good(including carton,spool, PE film, Air bubble film).Whether carton’s seal is complete |

OK |

|

2 |

Bare Wire Diameter |

0.40±0.01MM |

0.395-0.405 |

|

3 |

Overall Diameter |

0.60±0.020MM |

0.595-0.605 |

|

4 |

Conductor Resistance |

MAX: 144.3Ω/KM-MIN:130.65Ω/KM |

140.6Ω/KM |

|

5 |

Elongation |

MIN:20% |

31.4-34.9% |

|

6 |

Solder ability |

420± 5℃ 1-2.5 Secs |

OK |

1. high impact strength.

2. good weather resistance.

3. Good chemical environment.

4. Excellent abrasion resistance on the surface of the slip characteristics.

5. water absorption is small, so the size stability is good.

6. the proportion of commercial polyamide is the smallest.

7. Excellent impact resistance at low temperature.

8. Good gas resistance:

(1) small proportion, small water absorption, small change in physical properties after water absorption.

(2) The molding temperature range is large, the product size is stable, low temperature impact strength is high, good weather resistance.

(3) Excellent oil and chemical resistance, oil resistance, gasoline, fuel liquid, all kinds of liquid, metal salt solution, etc.

(4) Good self-lubrication, excellent wear resistance, excellent fatigue resistance.

(5) Excellent processing properties, like other materials developed by the high performance polymer division.

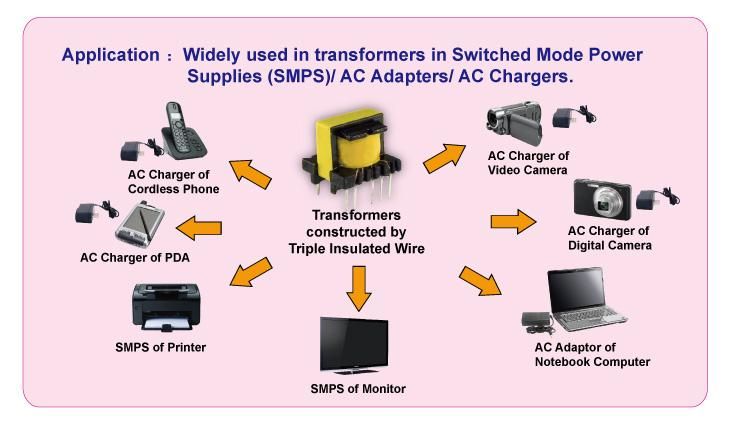

1. Easy to winding;

2. High insulation voltage, can leave out insulation tape, insulation layer;

3. Excellent wear resistance makes it possible for high-speed automatic winding;

4. Three layers of insulation protection, no pinhole phenomenon;

5. Can be soldered directly without stripping insulation layer.

Different insulating layer materials for different occasions, such as insulation layer for ETFE, due to high temperature resistance and high insulation, and widely used in high-frequency transformer, computer power supply, mobile phone charger; PFA&ETFE insulation layer, used in communication, transformer insulation lines and magnetic components.

Triple Insulated Wire

1.Production standard range:0.1-1.0mm

2.Withstand voltage class, class B 130℃, class F 155℃.

3.Excellent withstand voltage characteristics, breakdown voltage greater than 15KV, obtained reinforced insulation.

4.No need to peel off the outer layer can be direct welding, solder ability 420℃-450℃≤3s.

5.Special abrasive resistance and surface smoothness, staticfriction coefficient ≤0.155, the product can meet the automatic winding machine high-speed winding.

6.Resistant chemical solvents and impregnated paint performance, Rating voltage Rated voltage(working voltage)1000VRMS, UL.

7.High strength insulation layer toughness, repeated bending strethc, the insulation layers will not crack damage.