Class180 1.20mmx0.20mm Ultra-thin enameled flat copper wire

| Test Report: 1.20mm*0.20mm AIW Hot Air Self-bonding Flat Wire | ||||

| Item | Characteristics | Standard | Test Result | |

| 1 | Appearance | Smooth Equality | Smooth Equality | |

| 2 | Conductor Diameter(mm) | Width | 1.20±0.060 | 1.195 |

| Thickness | 0.20±0.009 | 0.197 | ||

| 3 | Thickness of Insulation(mm) | Width | Min.0.010 | 0.041 |

| Thickness | Min.0.010 | 0.035 | ||

| 4 | Overall Diameter

(mm) |

Width | Max.1.250 | 1.236 |

| Thickness | Max.0.240 | 0.232 | ||

| 5 | Solderability 390℃ 5S | Smooth with no draff | OK | |

| 6 | Pinhole(pcs/m) | Max ≤3 | 0 | |

| 7 | Elongation(%) | Min ≥30 % | 40 | |

| 8 | Flexibility and Adherence | No crack | No crack | |

| 9 | Conductor Resistance

(Ω/km at 20℃) |

Max. 79.72 | 74.21 | |

| 10 | Breakdown Voltage(kv) | Min. 0.70 | 2.00 | |

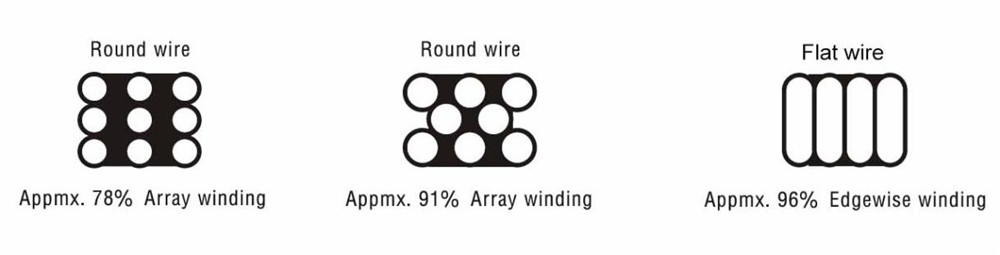

1.Occupy a smaller volume

Flat enameled wire takes up less space than enameled round wire, which can save 9-12% of space, and the production volume of smaller and lighter electronic and electrical products will be less affected by the coil volume

2. High space factor

Under the same winding space conditions, the space factor of the flat enameled wire can reach more than 95%, which solves the bottleneck problem of coil performance, makes the resistance smaller and the capacitance larger, and meets the requirements of large capacitance and high load application scenarios

3. Larger cross-sectional area

Compared with the round enameled wire, the flat enameled wire has a larger cross-sectional area, and its heat dissipation area is also increased accordingly, the heat dissipation effect is significantly improved, and the "skin effect" can also be greatly improved (when the alternating current passes through the conductor, the current will be concentrated in the conductor. The surface of the conductor flows through), reducing the loss of high-frequency motor.

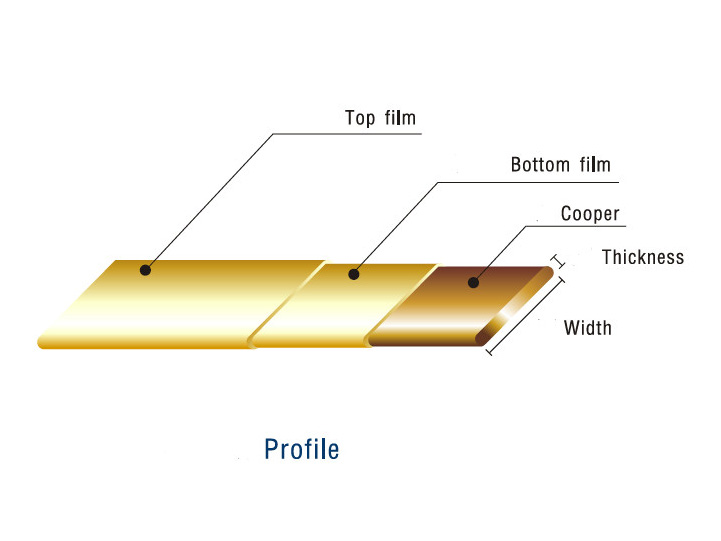

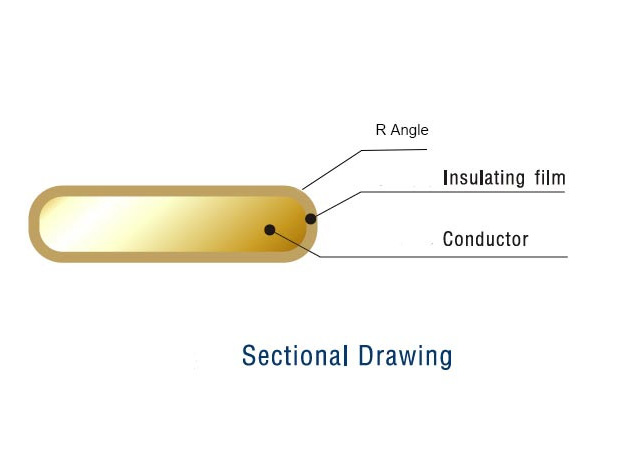

• Conductor dimension is high precision

• Insulation is coated uniformly and adhesively.Good insulation property and withstand voltage is more than 100V

• Good winding and bending property.Elongation is more than 30%

• Good radiation resistance and heat resistance, the temperature class can reach up to 240℃

• We have many different kinds and sizes of flat wire in self-bonding and solderable,with short shipment lead time and low MOQ.

•Inductor •Motor •Transformer

•Power Generator •Voice Coil •Solenoid Valve

5G Base Station Power Supply

Aerospace

Maglev Trains

Wind Turbines

New Energy Automobile

Electronics

We produces costom rectangular enaemeled copper wire in temperature classes 155°C-240°C.

-Low MOQ

-Quick Delivery

-Top Quality

Ruiyuan attracts many outstanding technical and management talents, and our founders have built the best team in the industry with our long-term vision. We respects the values of each employee and provides them with a platform to make Ruiyuan a great place to grow a career.