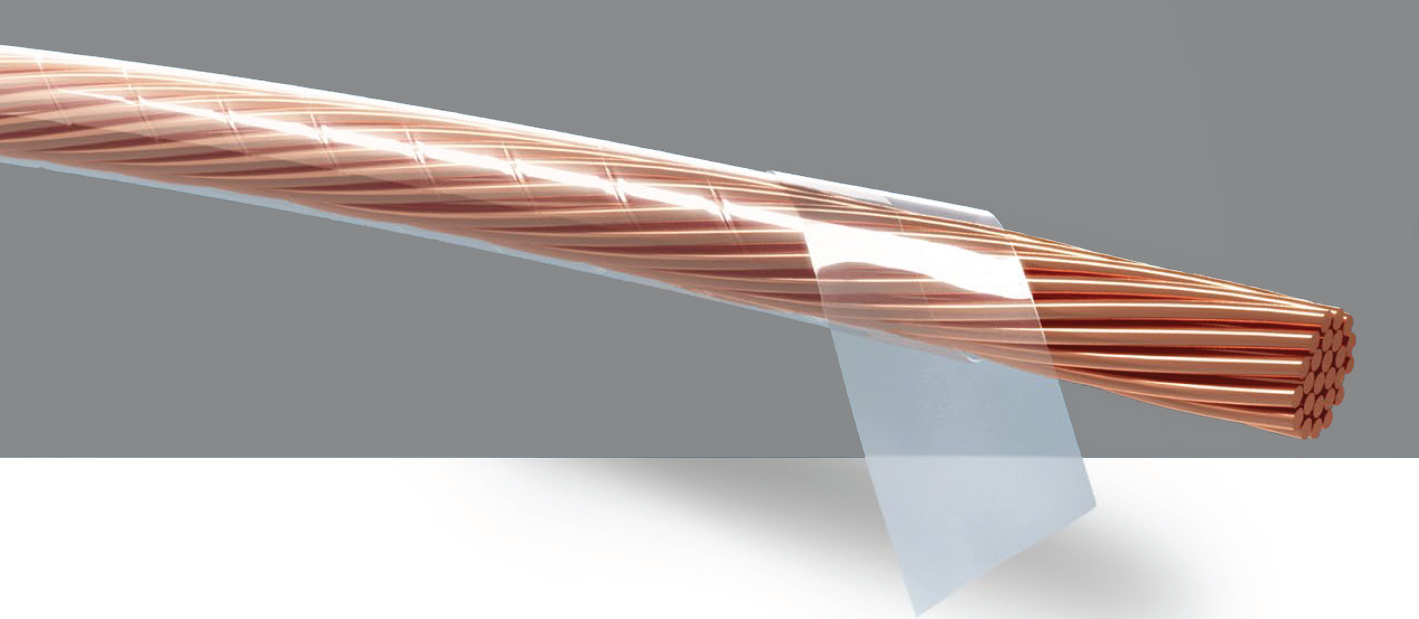

Taped litz wire, as a main products supplied at Tianjin Ruiyuan, can also be called mylar litz wire. “Mylar” is a film that was developed and industrialized by American enterprise DuPont. PET film was the first mylar tape invented. Taped Litz Wire, guessed by its name, is multi-strands of single enameled copper wire bundled together, and then wrapped by layers of mylar film at different wrapping rate, so as to increase its property for insulation voltage and shield radiation. It can be a suitable substitute for silk covered litz wire.

Tables below indicates some of most commonly used tapes at Tianjin Ruiyuan.

|

Tape |

Recommended Operating Temperature |

Characteristics |

|

Polyester(PET) Mylar®(Heat sealable grades available) |

135°C |

- High dielectric strength - Good abrasion often used as binder or barrier under extruded jackets and textile serves or braids |

|

Polyimide Kapton® (Heat sealable & adhesive grades available) |

240°C (Up to 400°C under certain conditions) |

- Very high dielectric strength - Very good chemical resistance - UL 94 V-O flame rating - Excellent mechanical properties |

|

ETFE(processing temperature) |

200°C |

-superior impact strength -good abrasion and cut through resistance -lower weight per unit volume |

|

F4(PTFE)

|

260°C |

-water-repellant -low friction material -Chemically inert -high temperature performance, robust pressure and high arc resistance |

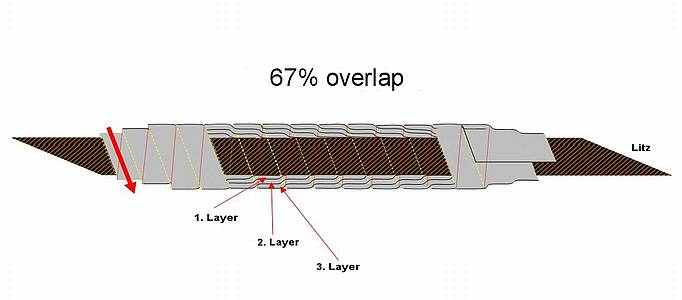

Degree of Overlapping

The degree of overlapping of two adjacent tape windings is defined by the gradient angle between tape and litz wire during the taping process. The overlapping determines the number of tape layers located on top of each other and thus the insulation thickness of the litz wire. Our highest overlapping rate is 75%.

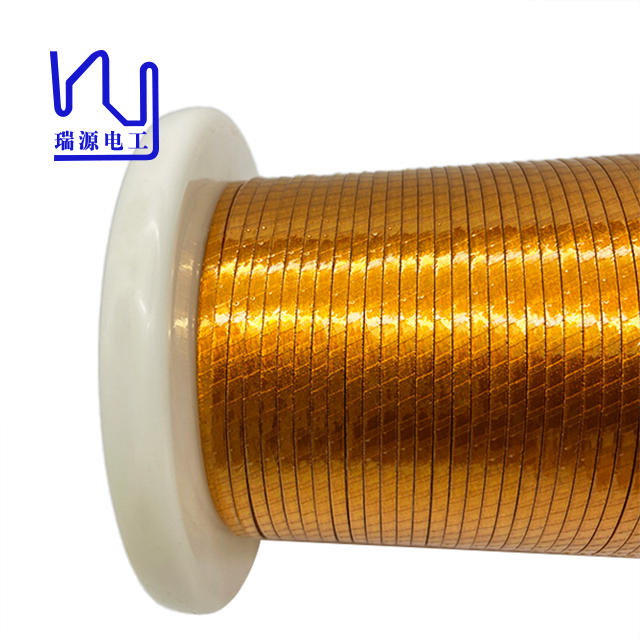

Flat Taped Litz Wire

Post time: Mar-13-2023