Products

-

41AWG 0.071mm Heavy formvar guitar pikcup wire

Formvar is one of the earliest synthetic enamel of formaldehyde and substance hydrolytic polyvinyl acetate after polycondensation which dates back to the 1940s. Rvyuan Heavy Formvar enameled pickup wire is classic and often used on the 1950s, 1960s vintage pickups while people of the time also wind their pickups with plain enameled wire.

-

Custom 0.067mm Heavy Formvar Guitar Pickup Winding Wire

Wire Type: Heavy Formvar Guitar Pickup Wire

Diameter: 0.067mm,AWG41.5

MOQ: 10Kg

Color: Amber

Insulation: Heavy Formvar Enamel

Build: Heavy / Single /Customized Single Formvar -

UL System Certified 0.20mmTIW Wire Class B Triple Insulated Copper Wire

Triple insulated wire or reinforced insulated wire that is made up of three layers, comletely insolates the primary from secondary of the transformer. Reinforced insulation provide various safety standards that eliminates barriers, inter layers tapes and insulating tubes in a transformer.

The most advantage of the triple insulated wire is not only higher breakdown voltage that is up to 17KV, but In addition to reduction in size and economy in material costs of the transformer manufacture.

-

Class B / F Triple Insulated Wire 0.40mm TIW Solid Copper Winding Wire

Here are many brands and types of triple insulated wire in the market, that is not easy to choose the right one you need. Here we bring you the main types of triple insulated wire with their own features for easier chosen, and all the triple insulated wire pass UL system certificate

-

Class 130/155 Yellow TIW Triple insulated winding wire

Triple insulated wire or three layers insulated wire is a kind of winding wire but with three extruded insulation layers in safety standards around the circumference of the conductor.

Triple insulated wire(TIW) are used in switched mode power supplies and realize miniaturization and cost reductions as no insulation tape or barrier tape is required between the primary and secondary windings of the transformers. Multiple thermal class options: class B(130), Class F(155) satisfy most applications.

-

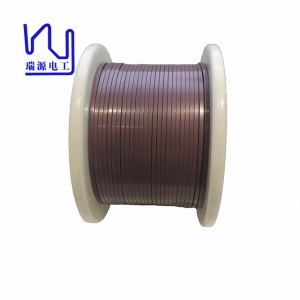

SFT-EIAIW 5.0mm x 0.20mm High Temperature Rectangular Enameled Copper Winding Wire

The enameled flat wire is an enameled wire with a rectangular conductor with an R angle. It is described by parameters such as conductor narrow boundary value, conductor wide boundary value, paint film heat resistance grade and paint film thickness and type. The conductors can be copper, copper alloys or CCA copper clad aluminum.

-

SFT-AIW220 0.12×2.00 High Temperature Rectangular Enameled Copper Wire

Enamelled flat wire refers to the winding wire obtained by drawing, extruding and rolling through a certain specification of mold by using an enameled round copper wire, and then coated with insulating varnish for many times.

Including enameled copper flat wire, enameled aluminum flat wire… -

EIAIW 180 4.00mmx0.40mm Custom Rectangular Enameled Copper Wire For Motor Winding

Custom Product Introduction

This custom-made wire 4.00*0.40 is 180°C Polyesterimide copper flat wire. The customer uses this wire on the high-frequency motor. Compared with the enameled round wire, the cross-sectional area of this flat wire has a larger cross-sectional area, and its heat dissipation area is also increased accordingly, and the heat dissipation effect is significantly improved. At the same time, it can greatly improve the “skin effect”, thereby reducing the loss of high-frequency motor. Improved efficiency for customers. -

Custom PEEK wire, rectangular enameled copper winding wire

The current enameled rectangular wires are suitable for most applications, however still some shortages in some specific requirements:

Higher thermal class over 240C,

Excellent solvent resistant capacity especially immerse the wire into the water or oil completely for long time.

The both requirements are typical demand of new energy car. Therefore, we found the material PEEK to combine our wire together to satisfy the such demand. -

Class180 1.20mmx0.20mm Ultra-thin enameled flat copper wire

The flat enameled copper wire is different from the traditional round enameled copper wire. It is compressed into a flat shape at the initial stage, and then coated with insulating paint, thus ensuring the good insulation and corrosion resistance of the wire surface. Furthermore, compared with copper round wire, enameled copper flat wire also has major breakthroughs in current carrying capacity, transmission speed, heat dissipation performance and occupied space volume.

Standard: NEMA, IEC60317,JISC3003,JISC3216 or customized

-

AIWSB 0.5mm x1.0mm Hot Wind Self Bonding Enameled Copper Flat Wire

In fact, flat enameled copper wire refers to a rectangular enameled copper wire, which consists of a width value and a thickness value. The specifications are described as:

Conductor thickness (mm) x conductor width (mm) or conductor width (mm) x conductor thickness (mm) -

AIW220 2.2mm x0.9mm High Temperature Rectangular Enameled Copper Wire Flat Winding Wire

The advancement of science and technology has made the volume of electronic components continue to shrink. Motors weighing dozens of pounds can also be reduced and installed on disk drives. With the miniaturization of electronic appliances and other products, miniaturization has become the trend of the times. It is against the background of this era that the demand for fine enameled copper flat wire is also increasing day by day.