UL System Certified 0.20mmTIW Wire Class B Triple Insulated Copper Wire

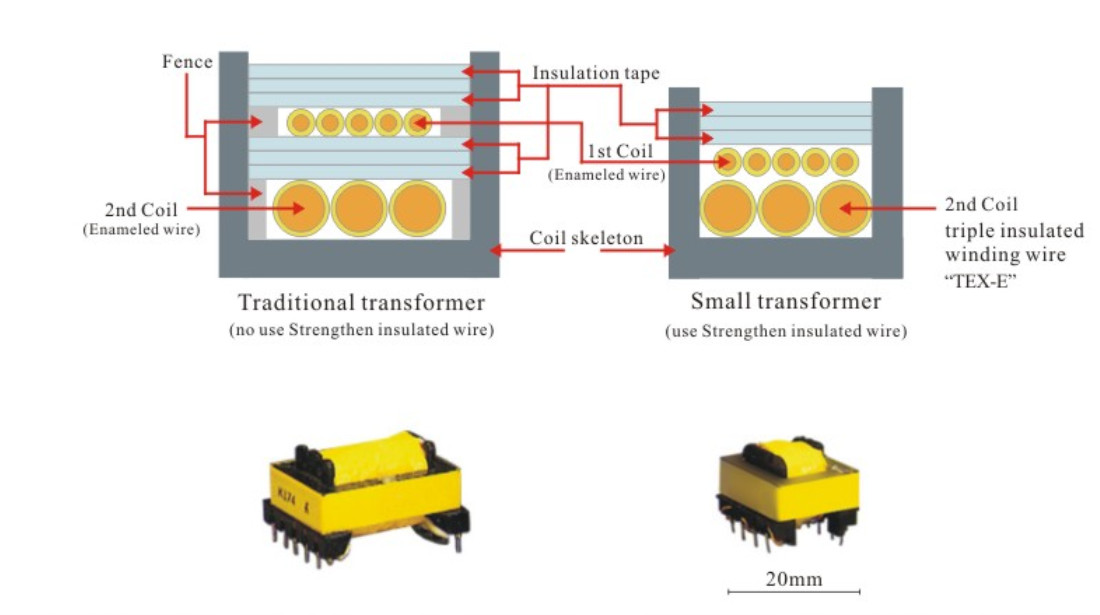

1.No need inter lamination tape and fence. That reduce the size of transformer

2.The insulating coating can be soldered directly that improve process efficiency

3.The insulation of is strong enough to withstand high-speed winding on the automatic wire winder to reduce production costs. The recommended soldered temperature range 420℃-450℃ ≤3seconds

4.Heat resistance range from class B(130) to class H(180)

5.Different color options: Yellow, Blue, Pink Red, Green and customized color.

Here is the picture how the triple insulated wire miniature the transformer to reduce the costs

| Model | Traditional Transformer

(No Use Triple insulated wire) |

Smaller transformer

(use TIW) |

|

| Output voltage | 20W | 20W | |

| Volume | cm³ | 36 | 16 |

| % | 100 | 53 | |

| Weight | g | 70 | 45 |

| % | 100 | 64 | |

Here are different types and size range of triple insulated wire we always provide, you select the most suitable ones by the required function or the applications

| escription | Designation | Thermal Grade(℃) | Diameter

(mm) |

Breakdown Voltage(KV) | Solderability

(Y/N) |

| Triple Insulated Copper Wire | Class B/F/H | 130/155/180 | 0.13mm-1.0mm | ≧17 | Y |

| Tinned | 130/155/180 | 0.13mm-1.0mm | ≧17 | Y | |

| Self Bonding | 130/155/180 | 0.13mm-1.0mm | ≧15 | Y | |

| seven strand litz wire | 130/155/180 | 0.10*7mm-

0.37*7mm |

≧15 | Y |

1.Production standard range:0.1-1.0mm

2.Withstand voltage class, class B 130℃, class F 155℃.

3.Excellent withstand voltage characteristics, breakdown voltage greater than 15KV, obtained reinforced insulation.

4.No need to peel off the outer layer can be direct welding, solder ability 420℃-450℃≤3s.

5.Special abrasive resistance and surface smoothness, staticfriction coefficient ≤0.155, the product can meet the automatic winding machine high-speed winding.

6.Resistant chemical solvents and impregnated paint performance, Rating voltage Rated voltage(working voltage)1000VRMS, UL.

7.High strength insulation layer toughness, repeated bending strethc, the insulation layers will not crack damage.

Founded in 2002, Ruiyuan has been in the manufacture of enamelled copper wire for 20 years.We combine the best manufacturing techniques and enamel materials to create a high-quality, best-in-class enameled wire. The enameled copper wire lies at the heart of technology we use every day – appliances, generators, transformers, turbines, coils and much more. Nowadays, Ruiyuan has the global footprint to support our partners in marketplace.