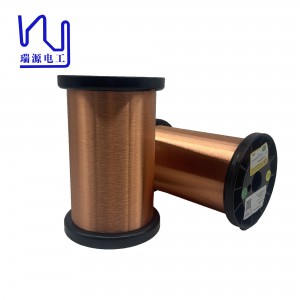

2UEW155 0.075mm copper enameled winding wire for Micro devices

This wire is classified as solderable magnet wire, meaning it can be easily soldered to other components, making it an important material in the production of microelectronics and medical devices.

In the field of microelectronics, enamelled copper wire plays a vital role in the manufacturing of complex precision electronic components. Its ultra-fine diameter makes it suitable for winding coils and transformers in microdevices such as sensors, actuators and micromotors. The ability of enamelled copper wire to withstand high temperatures makes it ideal for use in microelectronics, ensuring the longevity and efficiency of the equipment using it.

Enameled copper wire is widely used in the field of medical devices. The wire's fine gauge and thermoelasticity make it an important component in the manufacturing of medical sensors, pacemakers and imaging devices. Its high electrical conductivity is critical for precise signal transmission in medical monitoring and diagnostic equipment, contributing to the accuracy and reliability of these critical instruments.

Additionally, the solderable nature of enamelled copper wire allows for seamless integration in complex medical devices, ensuring a strong connection and optimal functionality. The importance of enamelled copper wire in the microelectronics and medical device industries cannot be overstated. Its unique combination of ultra-fine diameter, high temperature resistance and weldable properties makes it integral to the development of cutting-edge technologies in these areas.

As the demand for miniaturized, high-performance electronics and medical devices continues to grow, enameled copper wire will undoubtedly remain a key enabler of innovation, playing a key role in driving technological advancement and improving healthcare worldwide.

·IEC 60317-23

·NEMA MW 77-C

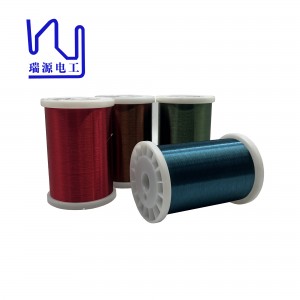

·customized according to customer requirements.

|

Test Items

|

Requirements

|

Test Data |

||

|

1st Sample |

2nd Sample |

3rd Sample |

||

| Appearance |

Smooth & Clean |

OK |

OK |

OK |

| Conductor Diameter |

0.075mm ±0.002mm |

0.075 |

0.075 |

0.075 |

| Thickness of Insulation |

≥ 0.008 mm |

0.010 |

0.010 |

0.010 |

| Overall Diameter |

≤ 0.089 mm |

0.085 |

0.085 |

.085 |

| DC Resistance |

≤ 4.119 Ω/m |

3.891 |

3.891 |

3.892 |

| Elongation |

≥ 15% |

22.1 |

20.9 |

21.6 |

| Breakdown Voltage |

≥550 V |

1868 |

2051 |

1946 |

| Pin Hole |

≤ 5 faults/5m |

0 |

0 |

0 |

| Adherence |

No cracks visible |

OK |

OK |

OK |

| Cut-through |

230℃ 2min No breakdown |

OK |

OK |

OK |

| Heat Shock |

200±5℃/30min No cracks |

OK |

OK |

OK |

| Solderability |

390± 5℃ 2 Sec No slags |

OK |

OK |

OK |

Automotive coil

sensor

special transformer

special micro motor

inductor

Relay

Customer Oriented,Innovation brings more Value

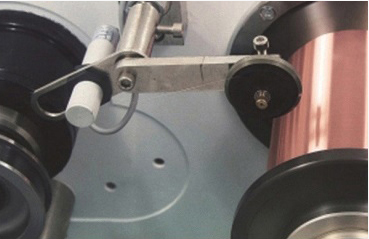

RUIYUAN is a solution provider, which requires us to be more professional on wires, insulation material and your applications.

Ruiyuan has a heritage of innovation, along with advancements in enameled copper wire, our company has grown through an unwavering commitment to integrity, service and responsiveness to our customers.

We look forward to continuing to grow on the basis of quality, innovation and service.

7-10 days Average delivery time.

90% European and North American customers. Such as PTR,ELSIT, STS etc.

95% Repurchase rate

99.3% Satisfaction rate. Class A supplier verified by German customer.