China OEM Enameled Copper Magnet Wire - Class 180 Hot air self-adhesive magnet winding copper wire – Ruiyuan

China OEM Enameled Copper Magnet Wire - Class 180 Hot air self-adhesive magnet winding copper wire – Ruiyuan Detail:

SBEIW Heat-resistant self-bonding enameled copper wire with composite coatings can be used for winding when they are activated by baking or electric heating to make bond coat of the wire attached to each other and shape the wire into a whole automatically and compactly after cooling. Compared with ordinary enameled copper wire, they feature better flexibility. During winding or pull of tension, the film remains intact. SBEIW is also resistant to sulfuric acid, sodium hydroxide and other acid, alkali, etc. and has good adhesiveness. With the whole world calling for environmental protection, the most advantageous feature of our self bonding wire is to save energy and improve environmental pollution. By comparison, conventional armature winding, this wire also has a more conspicuous advantage of simplifying manufacturing process of coil winding than conventional wire. In many occasions, there’ s no need for banding, impregnation, cleaning, etc. saving equipment use, power and labor so to be conducive to automatic winding and improvement of product quality. They are bonded at 120 ~ 170℃ to take into shape after half an hour baking bonding. The self bonding wire can also be bonded together by heat from electric power. As diameter varies and voltage and current is not different, the above-mentioned temperature range or measurement of certain voltage and current is for reference to determine the process parameters of bonding.

Our SBEIW is widely used in the disk type electric machine in car that is distinctive from other motors including micro motors and special motors.

1.compact structure, small axial size, armature without iron core, small inertia, continual start and good control response.

2.Disk type electric machine has small inductance (due to no iron core), good commutation performance. Its service life of the carbon brush can reach more than 2 times of motor with iron core. For brushless motor, cost of control components is reduced.

3.Large force and high efficiency. High duty ratio of conductor contributes to large force. Permanent magnet structure without iron core make working efficiency 1.2 times of motor with iron core. There’ s no iron consumption and excitation loss.

4. Large starting torque, tough mechanical characteristics and large motor overload

5.Low cost and light weight.

SBEIW Heat resistant self-adhesive magnet wire composite coat can be bonded by baking or electrification and form a solid structure after cooling. Some of its advantageous features make it fitted to manufacture small and special electric machine requiring particular technology. It’ s characterized by simple, time-saving, energy saving, and environmental manufacturing process and remarkable performance in motor

| Thermal class | Size range | Standard |

| 180/H | 0.040-0.4mm | IEC60317-37 |

Transformer

Motor

Ignition coil

Voice Coil

Electrics

Relay

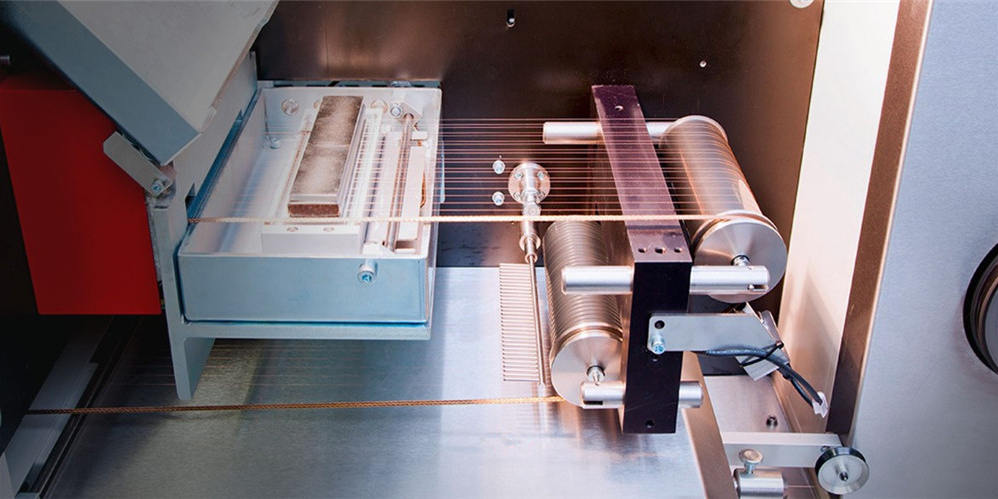

Drawing

Paint

Annealing

Baking

Cooling

Customer Oriented,Innovation brings more Value

RUIYUAN is a solution provider, which requires us to be more professional on wires, insulation material and your applications.

Ruiyuan has a heritage of innovation, along with advancements in enameled copper wire, our company has grown through an unwavering commitment to integrity, service and responsiveness to our customers.

We look forward to continuing to grow on the basis of quality, innovation and service.

7-10 days Average delivery time.

90% European and North American customers. Such as PTR,ELSIT, STS etc.

95% Repurchase rate

99.3% Satisfaction rate. Class A supplier verified by German customer.

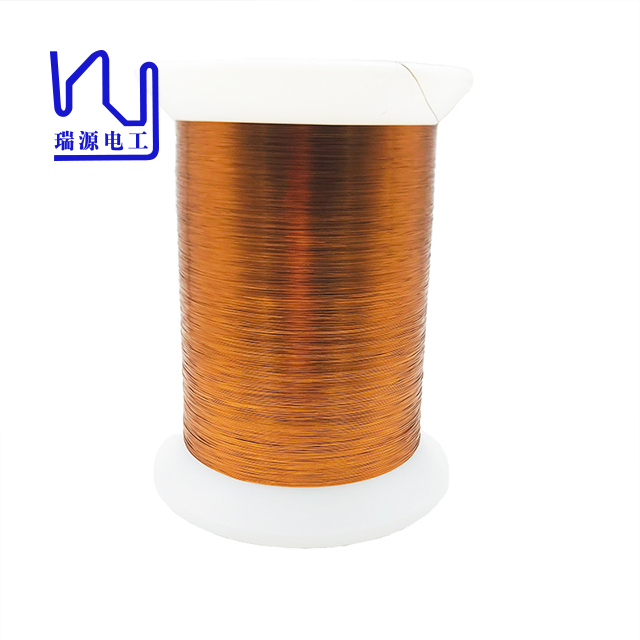

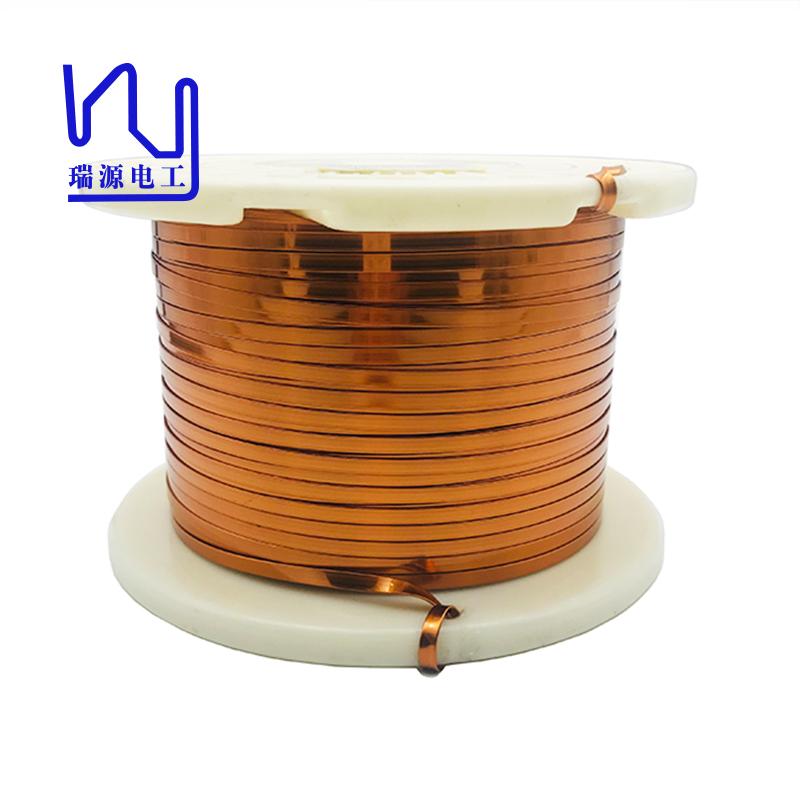

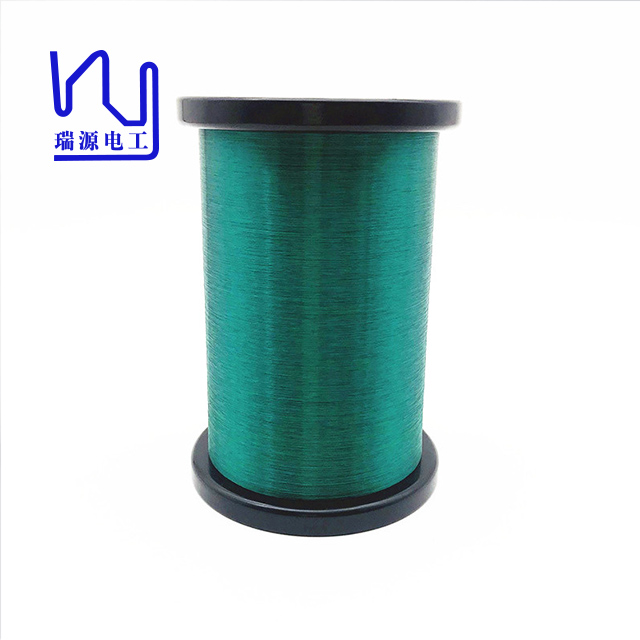

Product detail pictures:

Related Product Guide:

Assume full responsibility to satisfy all needs of our clients; achieve continual advancements by endorsing the expansion of our purchasers; turn into the final permanent cooperative partner of clientele and maximize the interests of clients for China OEM Enameled Copper Magnet Wire - Class 180 Hot air self-adhesive magnet winding copper wire – Ruiyuan , The product will supply to all over the world, such as: Latvia, Karachi, Turkmenistan, High output volume, top quality, timely delivery and your satisfaction are guaranteed. We welcome all inquiries and comments. We also offer agency service---that act as the agent in china for our customers. If you are interested in any of our products or have an OEM order to fulfill, please feel free to contact us now. Working with us will save you money and time.

This manufacturer can keep improving and perfecting products and service, it is in line with the rules of market competition, a competitive company.