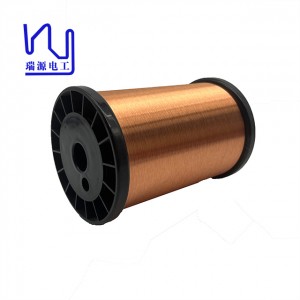

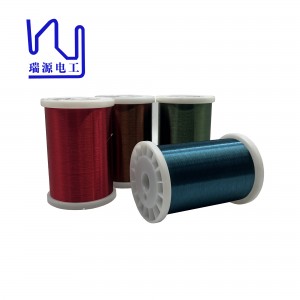

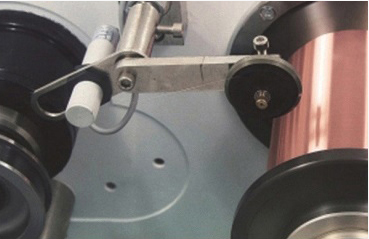

0.028mm – 0.05mm Ultra Thin Enameled Magnet Winding Copper Wire

Here we bring you the size range that is used in most applications. 0.028-0.050mm

Among them

G1 0.028mm and G1 0.03mm are chiefly winded for the secondary high-voltage transformers.

G2 0.045mm,0.048mm and G2 0.05mm are chiefly applied to ignition coils.

G1 0.035mm and G1 0.04mm are chiefly applied to relays

Requirements of enameled copper wire for different applications vary even for the same enameled copper wire. For example, withstand voltage is very important to magnet wires for ignition coils and high-voltage transformers. The thickness of enamel needs to be stringently controlled to ensure that withstand voltage meets requirements. To ensure consistency of outer diameter, we adopt the method of multiple times of thin enameling.

For relays, thinly enameled copper wire is usually applied as stability of the conductor resistance is vital to them. This requires us to pay great attention to select raw material and wire drawing process.

Our regular test items of enameled copper wire are as follows:

appearance and O.D

Elongation

Breakdown voltage

Resistance

Pinhole test(we can achieve 0)

|

Dia. (mm) |

Tolerance (mm) |

Enameled copper wire (Overall diameter mm) |

Resistance at 20℃ Ohm/m |

||||||||

|

Grade 1 |

Grade 2 |

Grade 3 |

|||||||||

| 0.028 |

±0.01 |

0.031-0.034 | 0.035-0.038 | 0.039-0.042 |

24.99-30.54 |

||||||

| 0.030 |

±0.01 |

0.033-0.037 | 0.038-0.041 | 0.042-0.044 |

24.18-26.60 |

||||||

| 0.035 |

±0.01 |

0.039-0.043 | 0.044-0.048 | 0.049-0.052 |

17.25-18.99 |

||||||

| 0.040 |

±0.01 |

0.044-0.049 | 0.050-0.054 | 0.055-0.058 |

13.60-14.83 |

||||||

| 0.045 |

±0.01 |

0.050-0.055 | 0.056-0.061 | 0.062-0.066 |

10.75-11.72 |

||||||

| 0.048 |

±0.01 |

0.053-0.059 | 0.060-0.064 | 0.065-0.069 |

9.447-10.30 |

||||||

| 0.050 |

±0.02 |

0.055-0.060 | 0.061-0.066 | 0.067-0.072 |

8.706-9.489 |

||||||

|

Breakdown voltage Min.(V) |

Elogntagion Min. |

Dia. (mm) |

Tolerance (mm) |

||||||||

|

G1 |

G2 |

G3 |

|||||||||

|

170 |

325 |

530 |

7% |

0.028 |

±0.01 |

||||||

|

180 |

350 |

560 |

8% |

0.030 |

±0.01 |

||||||

|

220 |

440 |

635 |

10% |

0.035 |

±0.01 |

||||||

|

250 |

475 |

710 |

10% |

0.040 |

±0.01 |

||||||

|

275 |

550 |

710 |

12% |

0.045 |

±0.01 |

||||||

|

290 |

580 |

780 |

14% |

0.048 |

±0.01 |

||||||

|

300 |

600 |

830 |

14% |

0.050 |

±0.02 |

||||||

|

Breakdown voltage Min.(V) |

Elogntagion Min. |

Dia. (mm) |

Tolerance (mm) |

||

|

G1 |

G2 |

G3 |

|||

|

170 |

325 |

530 |

7% |

0.028 |

±0.01 |

|

180 |

350 |

560 |

8% |

0.030 |

±0.01 |

|

220 |

440 |

635 |

10% |

0.035 |

±0.01 |

|

250 |

475 |

710 |

10% |

0.040 |

±0.01 |

|

275 |

550 |

710 |

12% |

0.045 |

±0.01 |

|

290 |

580 |

780 |

14% |

0.048 |

±0.01 |

|

300 |

600 |

830 |

14% |

0.050 |

±0.02 |

Transformer

Motor

Ignition coil

Voice Coil

Electrics

Relay

Customer Oriented,Innovation brings more Value

RUIYUAN is a solution provider, which requires us to be more professional on wires, insulation material and your applications.

Ruiyuan has a heritage of innovation, along with advancements in enameled copper wire, our company has grown through an unwavering commitment to integrity, service and responsiveness to our customers.

We look forward to continuing to grow on the basis of quality, innovation and service.

7-10 days Average delivery time.

90% European and North American customers. Such as PTR,ELSIT, STS etc.

95% Repurchase rate

99.3% Satisfaction rate. Class A supplier verified by German customer.