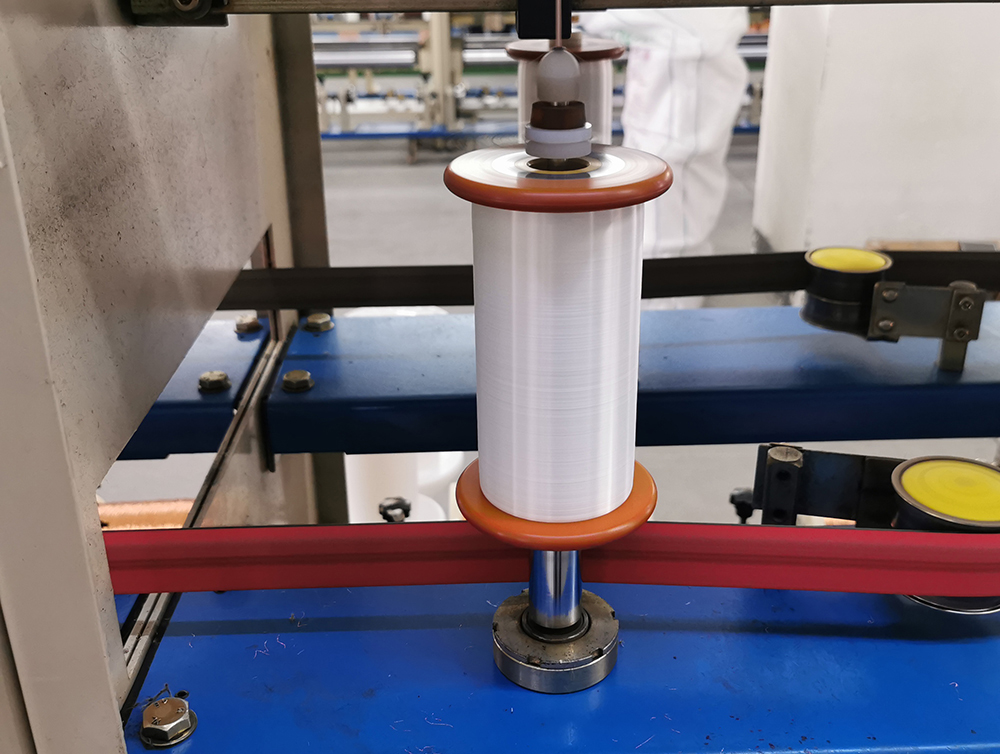

0.2mmx66 Class 155 180 Stranded Copper Litz Wire

| Test report: 0.2mm x 66 strands, thermal grade 155℃/180℃ | |||

| No. | Characteristics | Technical requests | Test Results |

| 1 | Surface | Good | OK |

| 2 | Single wire outer diameter(mm) | 0.216-0.231 | 0.220-0.223 |

| 3 | Single wire inner diameter(mm) | 0.200±0.003 | 0.198-0.20 |

| 4 | Overall diameter(mm) | Max. 2.50 | 2.10 |

| 5 | Pinhole Test | Max. 40pcs/6m | 4 |

| 6 | Breakdown Voltage | Min. 1600V | 3600V |

| 7 | Conductor ResistanceΩ/m(20℃) | Max. 0.008745 | 0.00817 |

·Increase Copper Density and Efficiencies

·Mitigation of Skin and Proximity Effect

·Reduce A.C. Losses

·Reduction of Footprint and Weight

·Minimum Eddy Current Losses

·Lowered Operating Temperatures

·Avoidance of "Hot Spots"

We can customize litz wire, according to the single wire diameter and strands number required by the customer. The specs are as follow:

·Single Wire Diameter: 0.040-0.500mm

·Strands: 2-8000pcs

·Overall Diamter: 0.095-12.0mm

Litz Wire Applications Include:

·Solar

·Inductive heating elements

·Power supply units

·Renewable energy

·Automotive

(Single-strand wire is used as the sample) Take 3 samples with a length of about 15cm from the same spool, and immerse one end of the sample with a length of about 4cm into the solder (tin 50, lead 50) tank specified in Table 1, and immerse them for the time in Table 1. After tinning, take it out and observe the soldering condition. The deep part should be completely soldered (the upper end of the immersed part is 10mm away from the test object), check whether the soldering tin is evenly attached, and there is no carbonized black shavings attached; the diameter should be less than 0.10mm When it is a conductor, use a winding tool to immerse the sample coil for about 50mm, and then determine the center of about 30mm.

Table1

| Conductor diameter(mm) | Solder Temperature(℃) | Immersion Tin Time (seconds) |

| 0.08~0.32 | 390 | 3 |

5G base station power supply

EV Charging Stations

Industrial Motor

Maglev Trains

Medical Electronics

Wind Turbines

Founded in 2002, Ruiyuan has been in the manufacture of enamelled copper wire for 20 years.We combine the best manufacturing techniques and enamel materials to create a high-quality, best-in-class enameled wire. The enameled copper wire lies at the heart of technology we use every day – appliances, generators, transformers, turbines, coils and much more. Nowadays, Ruiyuan has the global footprint to support our partners in marketplace.

Our Team

Ruiyuan attracts many outstanding technical and management talents, and our founders have built the best team in the industry with our long-term vision. We respects the values of each employee and provides them with a platform to make Ruiyuan a great place to grow a career.