0.2mm x 66 High Frequency Multipel Stranded Wire Copper Litz Wire

| Test report: 0.2mm x 66 strands, thermal grade 155℃/180℃ | |||

| No. | Characteristics | Technical requests | Test Results |

| 1 | Surface | Good | OK |

| 2 | Single wire outer diameter(mm) | 0.216-0.231 | 0.220-0.223 |

| 3 | Single wire inner diameter(mm) | 0.200±0.003 | 0.198-0.20 |

| 4 | Overall diameter(mm) | Max. 2.50 | 2.10 |

| 5 | Pinhole Test | Max. 40pcs/6m | 4 |

| 6 | Breakdown Voltage | Min. 1600V | 3600V |

| 7 | Conductor ResistanceΩ/m(20℃) | Max. 0.008745 | 0.00817 |

Litz wire is composed of multiple strands of enameled copper wire and twisted together. According to different applications, there are a variety of different insulating magnet wire choices, forming many circumferential surfaces, achieving a layer effect, reducing high-frequency resistance, and increasing the Q value, which is easier to design high-voltage, high-frequency coils. Our wire have passed multiple certifications,IS09001/IS014001/IATF16949/UL/RoHS/REACH

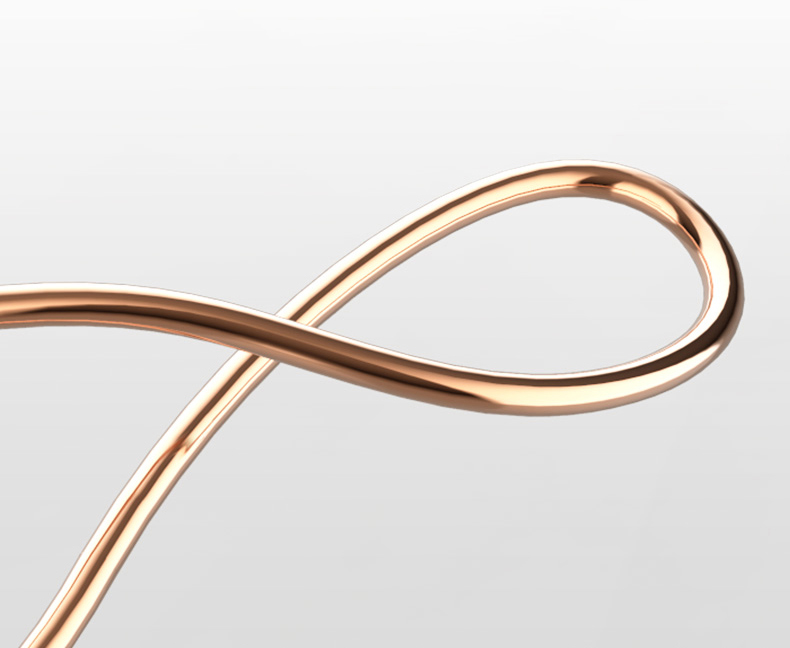

- Compared with the single enameled

- copper wire, the stranded wire has a larger

- surface area under the same conductor

- cross-sectional area, which can effectively

- suppress the influence of the skin effect and

- significantly improve the Q value of the coil.

High-frequency transformers and

inductors, communication equipment, ultrasonic

equipment, video equipment, radio equipment,

induction heating equipment, etc.

| Single Wire Diameter(mm) | 0.04-0.50 |

| Strands Number | 2-8000 |

| Overall Diameter(mm) | 0.095-12 |

| Temperature Class | Class B/Class F/Class H |

| Insulation Material | Polyurethane |

| Insulation Layer Thickness | 0UEW/1UEW/2UEW/3UEW |

| Twisted | Single twist / multiple twist |

| Breakdown Voltage(V) | >1200 |

| Twist Direction | Clockwise (S) / Anti-clockwise (Z) |

| Twist Pitch | 4-110mm |

| Color | Nature / Red |

| Spool | PT-4/ PT-10/ PT-15 |

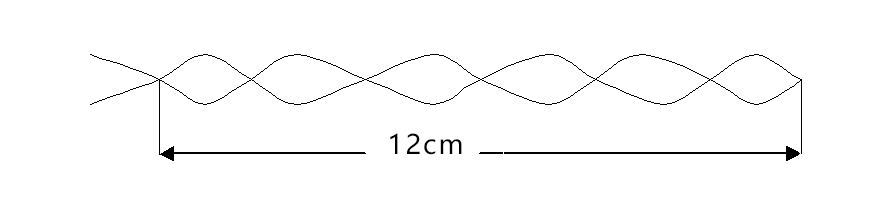

Single-strand insulation breakdown voltage test:

If the diameter of the conductor is thick than 0.05mm, take 3 samples with a length of about 50cm from the same spool, fold them into two wire segments (as shown in Figure 1), apply the tension shown in Table 1, and roll the part with a length of about 12cm for a specified number of times. After twisting, remove the tension, cut off the twisted part, apply a 50 or 60Hz approximate sine wave AC voltage between the two stranded conductors, and the voltage rises evenly at a rising speed of about 500V/S, thereby measuring the breaking voltage value. However, if the destruction occurs within 5 seconds, reduce the boosting speed so that the destruction occurs in more than 5 seconds. (When unqualified, when re-inspection, all three samples must meet the requirements of the attached table, and then judge.)

High quality copper material

high copper content

Strong electrical conductivity

Bend at will

Not easily broken

Has good flexibility

Table 1

| Conductor Diameter(mm) | Tension kgf(N) | Number of strands with a length of 12cm |

| 0.08-0.11 | 0.01(0.098) | 30 |

| 0.12-0.17 | 0.04(0.392) | 24 |

| 0.18-0.29 | 0.12(1.18) | 20 |

| 0.30-0.45 | 0.35(3.43) | 16 |

| 0.50-0.70 | 0.45(4.41) | 12 |

5G base station power supply

EV Charging Stations

Industrial Motor

Maglev Trains

Medical Electronics

Wind Turbines

Founded in 2002, Ruiyuan has been in the manufacture of enamelled copper wire for 20 years.We combine the best manufacturing techniques and enamel materials to create a high-quality, best-in-class enameled wire. The enameled copper wire lies at the heart of technology we use every day – appliances, generators, transformers, turbines, coils and much more. Nowadays, Ruiyuan has the global footprint to support our partners in marketplace.

Our Team

Ruiyuan attracts many outstanding technical and management talents, and our founders have built the best team in the industry with our long-term vision. We respects the values of each employee and provides them with a platform to make Ruiyuan a great place to grow a career.