2UEWF 0.18mm*4 Copper Stranded Wire High Frequency Litz Wire

The unique twisting of Litz wire places each twisted wire on the periphery of the conductor and equally sized on its center. This unique twisting method, combined with carefully selected wire diameters, enables Litz wire to minimize losses from two sources: skin effect and proximity effect.

|

single wire diameter (mm) |

0.18mm |

|

number of strands |

4 |

|

Maximum Outside Diameter(mm) |

0.49mm |

|

Insulation class |

class130/class155/class180 |

|

Film type |

Polyurethane/Polyurethane composite paint |

|

Film thickness |

0UEW/1UEW/2UEW/3UEW |

|

Pressure resistance |

>1600V |

|

Stranding direction |

Forward/ Reverse |

|

lay length |

14±2 |

|

Color |

copper/red |

|

Reel Specifications |

PT-4/PT-10/PT-15 |

|

Twisted |

Single twist/multiple twist |

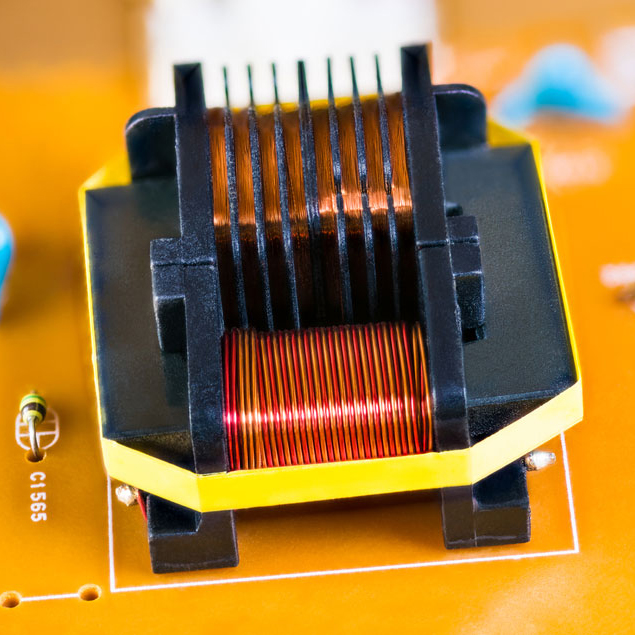

This 0.18*4 litz wire is customized. Customers choose Litz wire to reduce proximity effect losses. That is to say, the alternating current flowing through each conductor in a coil or winding creates an alternating magnetic field around it.

This magnetic field induces eddy currents in adjacent windings, changing the overall distribution of the current flowing through them and creating losses that appear as excess heat. The result is that the current is concentrated in the area of the conductor farthest from the nearby conductors that carry the current in the same direction.

This proximity effect increases with frequency. At higher frequencies, the proximity effect can increase the AC resistance of a conductor up to ten times its DC resistance.

The unique twist pattern of strands places each strand almost equally on the inside and outside of the wire, resulting in equal flux linkage and reactance for each strand. This results in an even distribution of current throughout the conductor. The resistance ratios (AC to DC) then approach unity, which is especially desirable in high-Q circuit applications.

Our products have passed multiple certifications: ISO9001/ISO14001/IATF16949/UL/ROHS/REACH/VDE(F703)

Founded in 2002, Ruiyuan has been in the manufacture of enamelled copper wire for 20 years.We combine the best manufacturing techniques and enamel materials to create a high-quality, best-in-class enameled wire. The enameled copper wire lies at the heart of technology we use every day – appliances, generators, transformers, turbines, coils and much more. Nowadays, Ruiyuan has the global footprint to support our partners in marketplace.

Our Team

Ruiyuan attracts many outstanding technical and management talents, and our founders have built the best team in the industry with our long-term vision. We respects the values of each employee and provides them with a platform to make Ruiyuan a great place to grow a career.