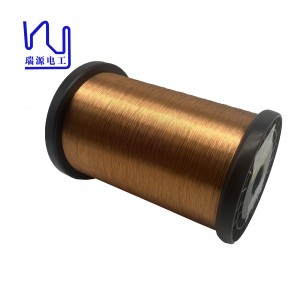

Polyurethane 0.18mm Solderable Hot Wind Self-adhesive Enameled Copper Wire

The hot air type self-adhesive enamelled package ensures the tight connection between the copper wire and the winding, increasing the stability and reliability of the coil,we also provide alcohol-type self-adhesive enamelled copper wires to meet the needs of different customers for fire protection and environmental protection.

1.The advantage of 0.18mm hot air self-adhesive enamelled copper wire lies in its excellent electrical conductivity and good heat resistance. This copper wire has low electrical resistivity and good electrical conductivity, which ensures high-efficiency electric current transmission, thereby increasing the working efficiency of the equipment.

2. Its excellent heat resistance means that it can operate in high temperature environment for a long time without damage. This hot air self-adhesive enamelled copper wire excels in high temperature applications such as power tools, communication equipment and automotive electronics.

A voice coil refers to a device that produces sound, such as speakers and headphones. It can be flexibly wound into coils of various shapes and sizes, providing audio equipment with high-quality sound quality and sound expression. Whether it's a hi-fi system or professional recording equipment, our self-adhesive enameled copper wire can meet your needs.

|

Test Item

|

Unit

|

Standard Value

|

Reality Value |

||

|

Min. |

Ave. |

Max. |

|||

|

Conductor dimensions |

mm |

0.18±0.003 |

0.180 |

0.180 |

0.180 |

|

(Basecoat dimensions) Overall dimensions |

mm |

Max.0.226 |

0.210 |

0.211 |

0.212 |

|

Insulation Film Thickness |

mm |

Min. 0.008mm |

0.019 |

0.020 |

0.020 |

|

Bonding Film Thickness |

mm |

Min.0.004 |

0.011 |

0.011 |

0.012 |

|

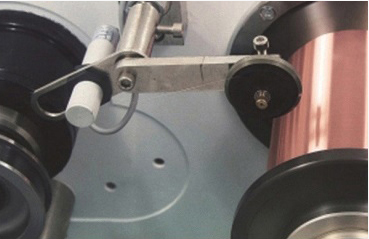

Continuity of covering(50V/30m) |

Pcs |

Max.60 |

Max.0 |

||

|

Flexibility |

|

/ |

/ |

||

|

Adherence |

|

no crack |

Good |

||

|

Breakdown Voltage |

V |

Min.2600 |

Min.4469 |

||

|

Resistance to Softening (Cut Through) |

℃ |

Continue 2 times pass |

300℃/Good |

||

|

(390℃±5℃) Solder test |

s |

/ |

/ |

||

|

Bonding Strength |

g |

Min. 29.4 |

50 |

||

|

Electrical Resistance(20℃) |

Ω/m |

Max.715.0 |

679 |

680 |

681 |

|

Elongation |

% |

Min.15 |

29 |

30 |

30 |

|

Breaking Load |

N |

Min |

/ |

/ |

/ |

|

Surface appearance |

|

Smooth |

Good |

||

Automotive coil

sensor

special transformer

special micro motor

inductor

Relay

Customer Oriented,Innovation brings more Value

RUIYUAN is a solution provider, which requires us to be more professional on wires, insulation material and your applications.

Ruiyuan has a heritage of innovation, along with advancements in enameled copper wire, our company has grown through an unwavering commitment to integrity, service and responsiveness to our customers.

We look forward to continuing to grow on the basis of quality, innovation and service.

7-10 days Average delivery time.

90% European and North American customers. Such as PTR,ELSIT, STS etc.

95% Repurchase rate

99.3% Satisfaction rate. Class A supplier verified by German customer.