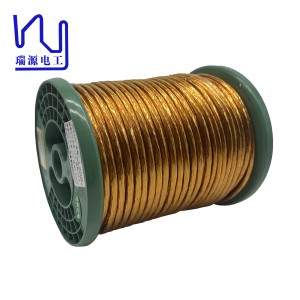

High Frequency 0.4mm*120 Taped Litz Wire Copper Conductor For Motor/Transformer

This taped litz wire has a single wire diameter of 0.4 mm, consists of 120 strands twisted together, and is wrapped with a polyimide film. Polyimide film is considered one of the best insulation materials currently, with high temperature resistance and excellent insulation properties. The numerous advantages of using taped litz wire make it a popular choice for magnetic applications in industries such as high frequency transformers, high power transformer manufacturing, and medical equipment, inverters, high frequency inductors and transformers.

·IEC 60317-23

·NEMA MW 77-C

·customized according to customer requirements.

One of the main advantages of taped Litz wire is its high frequency performance, which is due to the twisting of multiple wires. By twisting the individual strands together, the skin effect that causes increased resistance at high frequencies can be reduced. This property makes taped Litz wire an efficient conductor for high frequency applications, ensuring minimal power losses and improved performance in such systems.

In addition, using polyimide film as the insulating material provides excellent heat resistance and electrical insulation, making taped litz wire suitable for harsh environments where high temperatures and electrical isolation are critical. This not only ensures the safety and reliability of electrical equipment, but also extends the service life of components using wires.

|

Item |

Unit |

Technical requests |

Reality Value |

|

Conductor Diameter |

mm |

0.4±0.005 |

0.396-0.40 |

|

Single wire diameter |

mm |

0.422-0.439 |

0.424-0.432 |

|

O.D. |

mm |

Max. 6.87 |

6.04-6.64 |

|

Resistance (20℃) |

Ω/m |

Max.0.001181 |

0.00116 |

|

Breakdown Voltage |

V |

Min.6000 |

13000 |

|

Pitch |

mm |

130±20 |

130 |

|

No. of strands |

|

120 |

120 |

|

Tape/overlap% |

Min. 50 |

55 |

5G base station power supply

EV Charging Stations

Industrial Motor

Maglev Trains

Medical Electronics

Wind Turbines

Founded in 2002, Ruiyuan has been in the manufacture of enamelled copper wire for 20 years.We combine the best manufacturing techniques and enamel materials to create a high-quality, best-in-class enameled wire. The enameled copper wire lies at the heart of technology we use every day – appliances, generators, transformers, turbines, coils and much more. Nowadays, Ruiyuan has the global footprint to support our partners in marketplace.

Our Team

Ruiyuan attracts many outstanding technical and management talents, and our founders have built the best team in the industry with our long-term vision. We respects the values of each employee and provides them with a platform to make Ruiyuan a great place to grow a career.