USTC / UDTC 155/180 0.08mm*250 Profiled Silk Covered Litz Wire

The most advantage of silk severed profiled litz wire in comparison to ordinary USTC is Smaller volume with high frequency.With shape change to rectangular, filling rate is increased, while space factor is decreased,that provide extra space at very tight space of the complete product especially for wireless charger on cell phone. And multiple strands provide high frequency,larger surface allow larger current pass through, that make quick charge possible

|

Test report: 0.08mm x 250 strands,1.4*2.1mm profiled litz wire thermal grade 155℃ |

|||

|

No. |

Characteristics |

Technical requests |

Test Results |

|

1 |

Surface |

Good |

OK |

|

2 |

Single wire outer diameter (mm) |

0.087-0.103mm |

0.090-0.093mm |

|

3 |

Single wire inner diameter(mm) |

0.08±0.003mm |

0.078-0.08mm |

|

4 |

Overall diameter(mm) |

Length ≤2.10mm Width ≤1.40mm |

1.92-2.05mm(L) 1.24-1.36mm(W)

|

|

5 |

Twist Pitch |

27 |

27 |

|

6 |

Breakdown Voltage |

Min. 1100V |

2500V |

|

7 |

Conductor Resistance Ω/m(20℃) |

Max. 0.1510 |

0.1443 |

Single wire, 0.08mm or AWG 40 that can be changed according to your demand,however please note when the single wire is changed, the strands will be changed as well.As the same cross section, thinner single wire means more strands, if you need higher frequency, thinner single wire with more strands is better, and the price is higher as well.

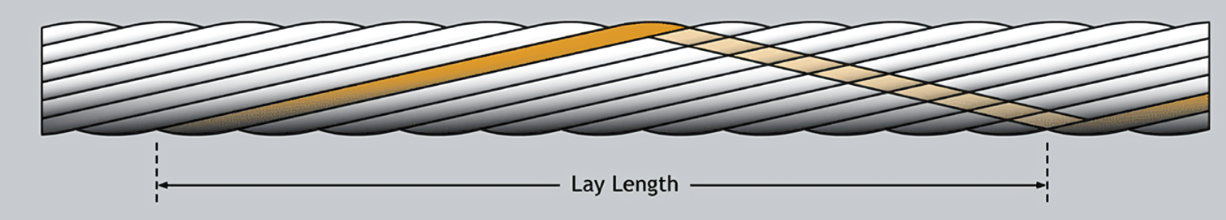

Twist pitch or length of lay, that can be customized as well, the smaller of the length of lay, the more tighten of the wire will be, we can give recommendation according to your application to reach the best condition of the wire.

5G base station power supply

EV Charging Stations

Industrial Motor

Maglev Trains

Medical Electronics

Wind Turbines

Founded in 2002, Ruiyuan has been in the manufacture of enamelled copper wire for 20 years.We combine the best manufacturing techniques and enamel materials to create a high-quality, best-in-class enameled wire. The enameled copper wire lies at the heart of technology we use every day – appliances, generators, transformers, turbines, coils and much more. Nowadays, Ruiyuan has the global footprint to support our partners in marketplace.

Our Team

Ruiyuan attracts many outstanding technical and management talents, and our founders have built the best team in the industry with our long-term vision. We respects the values of each employee and provides them with a platform to make Ruiyuan a great place to grow a career.