0.06mm * 1000 Film Wrapped Stranded Copper Enameled Wire Profiled Litz Wire

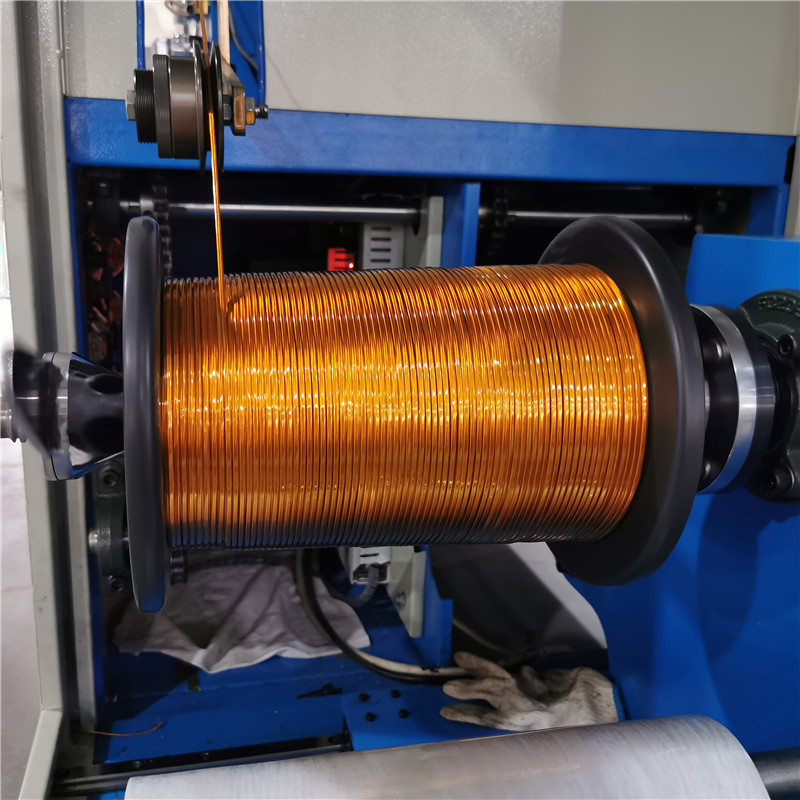

Film wrapped shaped litz wire has all the features of litz wire any Mylar wire:high frequency and high voltage. More strands with higher frequency, film wrapped that increase the breakdown voltage over 8000volts, up to 11000volts if there are three layers, that is greatly satisfy the demand of high voltage transformer. Meanwhile Rectangular or flat shape help the design could be smaller and compact, but with better heat dissipation compare with round Mylar Litz wire. Therefore, film wrapped shaped litz wire is an ideal option for high frequency and high voltage application.

1.High voltage withstand: Not matter which film PET or PI, the withstand breakdown voltage is at least 6000 volts with single layer. If the application need higher voltage, we choose double or triple layers, that will be over 10000 volts, that is enough for such application: high frequency, high voltage transformers, E-motors

2.Better sealing performance: No crevice on the film and when the film is wrapped on the wire, there is no gap between two adjacent layers, that protect the wire from water or any other liquid. However, we don’t suggest to immerse the wire into water

3.Double insulated film materials options

|

Material |

Polyester(PET) |

Polyimide(PI) |

|

Recommended Operation temperature |

130/155℃ |

180℃ |

|

Breakdown voltage |

Min.6000v |

Min.6000v |

|

Overlap Rate |

50%/67%/84% |

50%/67%/84% |

|

Color |

Transparent |

Brown |

Size Range

|

Biggest Width |

10 |

mm |

|

Width to Thickness Ratio |

4:1 |

mm |

|

Smallest Thickness |

1.5 |

mm |

|

Diameter of Single wire |

0.03-0.3mm |

mm |

1.Wireless charger

2.High frequency transformer

3.High frequency transducer

4.E-Motors

5G base station power supply

EV Charging Stations

Industrial Motor

Maglev Trains

Medical Electronics

Wind Turbines

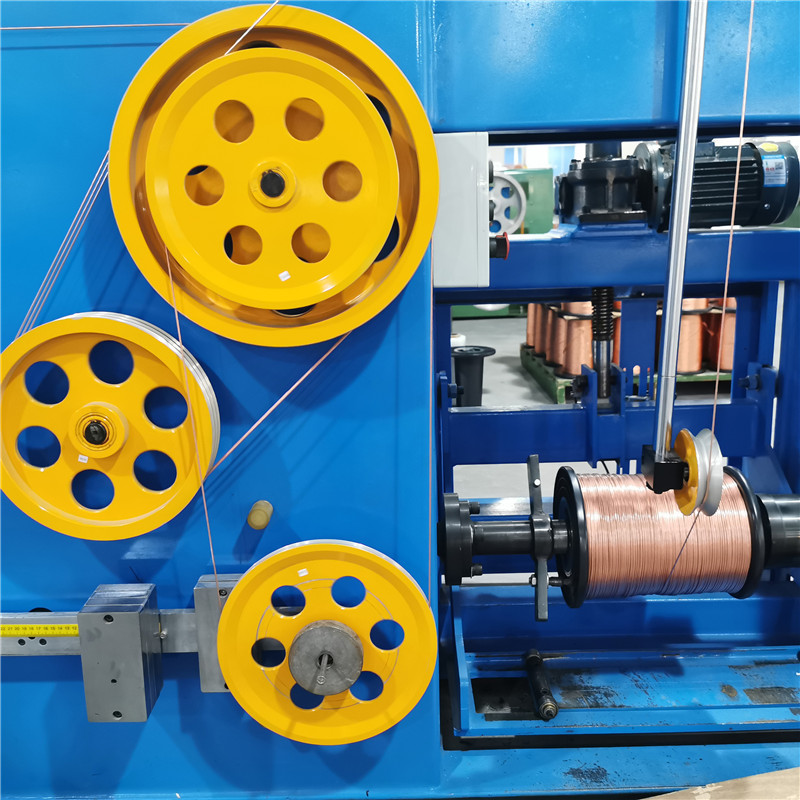

Founded in 2002, Ruiyuan has been in the manufacture of enamelled copper wire for 20 years.We combine the best manufacturing techniques and enamel materials to create a high-quality, best-in-class enameled wire. The enameled copper wire lies at the heart of technology we use every day – appliances, generators, transformers, turbines, coils and much more. Nowadays, Ruiyuan has the global footprint to support our partners in marketplace.

Our Team

Ruiyuan attracts many outstanding technical and management talents, and our founders have built the best team in the industry with our long-term vision. We respects the values of each employee and provides them with a platform to make Ruiyuan a great place to grow a career.